Method for synthesizing 2-methyl-1,4-naphthaquinone by taking ionic liquid as catalyst

An ionic liquid and catalyst technology, applied in the field of synthesizing 2-methyl-1, can solve the problems of chromium-containing wastewater and serious environmental pollution, and achieve the effect of fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Preparation of the first step ionic liquid

[0014] Stir equimolar pyridine (15.82g) and 1,4-butane sultone (27.23g) at room temperature for 3 days to obtain a white solid, wash with ethyl acetate to obtain a white solid ylide; then weigh equimolar The ylide (4.31g) and phosphoric acid (85%, 2.31g) were stirred and reacted at 80°C for 6h, and then rotary evaporated at 80°C for 4h to obtain the ionic liquid [SO 3 H-BPy][H 2 PO 4 ].

[0015] Synthesis of the second step 2-methyl-1,4-naphthoquinone

[0016] Add 0.05mol 2-methylnaphthalene, 0.25mol glacial acetic acid and 0.48mmol ionic liquid [SO 3 H-BPy][H 2 PO 4 ], when the above reactants were heated to 90°C, 20ml H 2 o 2 (30%, H 2 o 2 0.2 mol) was added dropwise in 20 minutes, and the temperature was maintained for 2 hours. During the reaction, samples were taken regularly for GC-MS qualitative and GC quantitative analysis, and the yield was 61%.

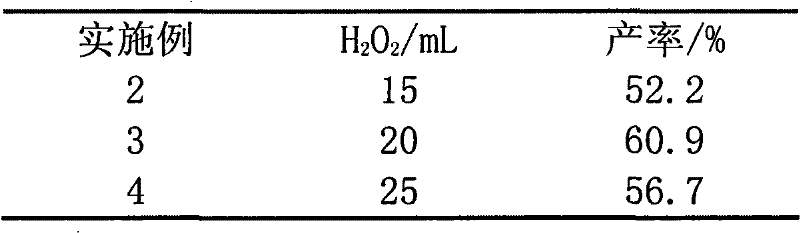

Embodiment 2-4

[0018] Except that following and catalyst (0.64mmol) are different, all the other are identical with embodiment 1, H 2 o 2 Dosage according to Table 1.

[0019] Table 1

[0020]

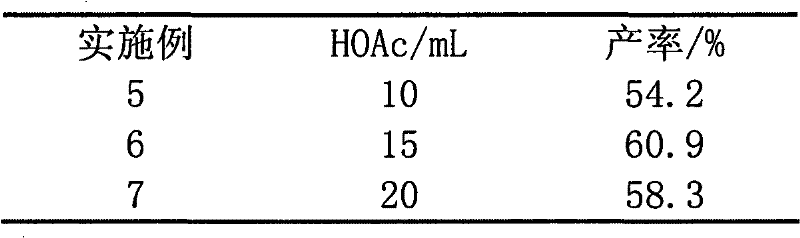

Embodiment 5-7

[0022] Except that following and catalyst (0.64mmol) are different, all the other are identical with embodiment 1, and HAOc consumption is by table 2 consumption.

[0023] Table 2

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com