Preparation method of carbasalate calcium

A technology of calcium carbasalate and calcium nitrate, applied in the field of fine chemical product preparation, can solve the problems of high production cost, difficult removal of residues, difficult production and the like, and achieves the effects of overcoming poor safety, low production cost, and concise production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

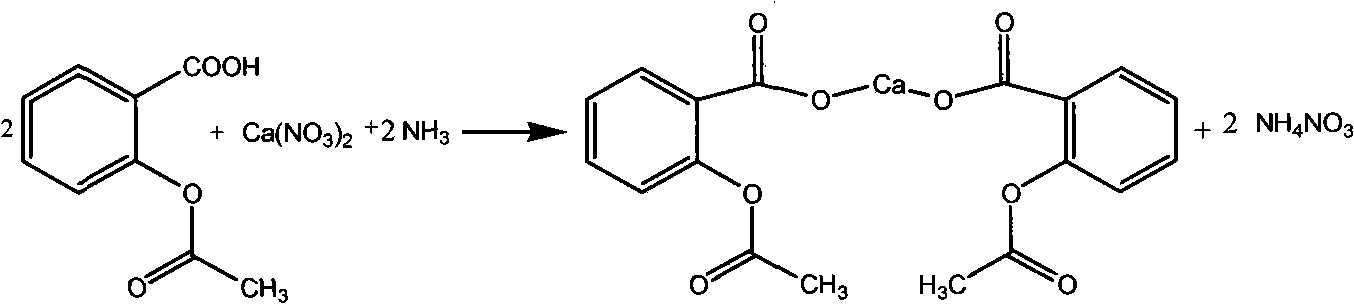

[0014] Preparation of aspirin calcium salt

[0015]

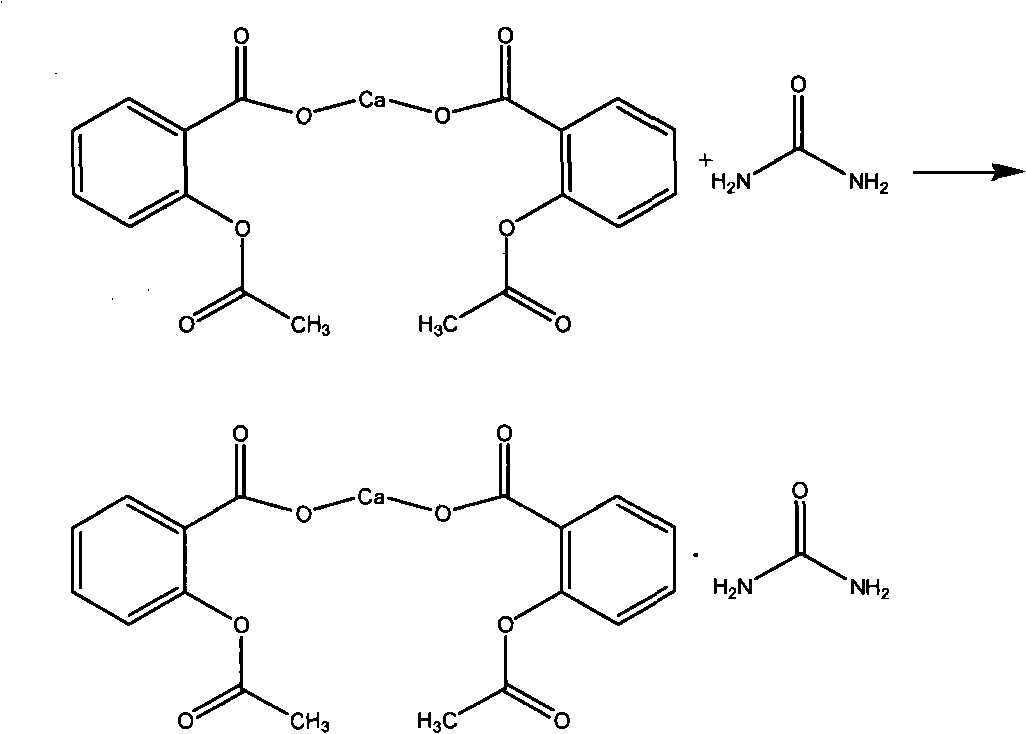

[0016] Preparation of Carboprine Calcium

Embodiment 1

[0018] (1) Pump 300kg of methanol into a 500L dissolving kettle, stir, increase the temperature to 35°C, add 50kg of aspirin, 10.5kg of urea, and 25kg of anhydrous calcium nitrate in sequence, keep it warm and stir for 40 minutes to dissolve it, press filter to 2000L In the crystallization kettle. The temperature of the crystallization kettle is cooled to 0-5°C through cooling water.

[0019] (2) Under the condition of maintaining a temperature of 0-5°C, start to pass ammonia gas and stir to make the pH value of the reaction system about 7.5, and the temperature of the reaction system does not exceed 10°C.

[0020] (3) Keep stirring, release the cooling water, add hot water around 35°C to circulate the temperature to increase the temperature in the crystallization kettle to 35°C. After keeping the crystallization for 5 hours, put the material into the centrifuge to filter and keep the centrifuge for 30 minutes.

[0021] (4) Pellet the dried material with a 12-mesh sieve, enter a d...

Embodiment 2

[0023] (1)Pump 250kg of ethanol into a 500L dissolving kettle, stir, increase the temperature to 35℃, add 50kg of aspirin, 10.5kg of urea, and 25kg of anhydrous calcium nitrate in sequence, keep it warm and stir for 40 minutes to make it completely dissolved, press filter to 2000L In the crystallization kettle. The temperature of the crystallization kettle is cooled to 0-5°C through cooling water.

[0024] (2) Under the condition that the temperature is maintained at 0-5°C, ammonia gas is introduced and stirred, so that the pH value of the reaction system is about 7.5, and the temperature of the reaction system does not exceed 10°C.

[0025] (3) Keep stirring, release the cooling water, add hot water around 35°C and circulate the temperature to increase the temperature in the crystallization kettle to 45°C. After keeping the crystallization for 5 hours, put the material into the centrifuge to filter and keep the centrifuge for 30 minutes.

[0026] (4) Pellet the dried material wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com