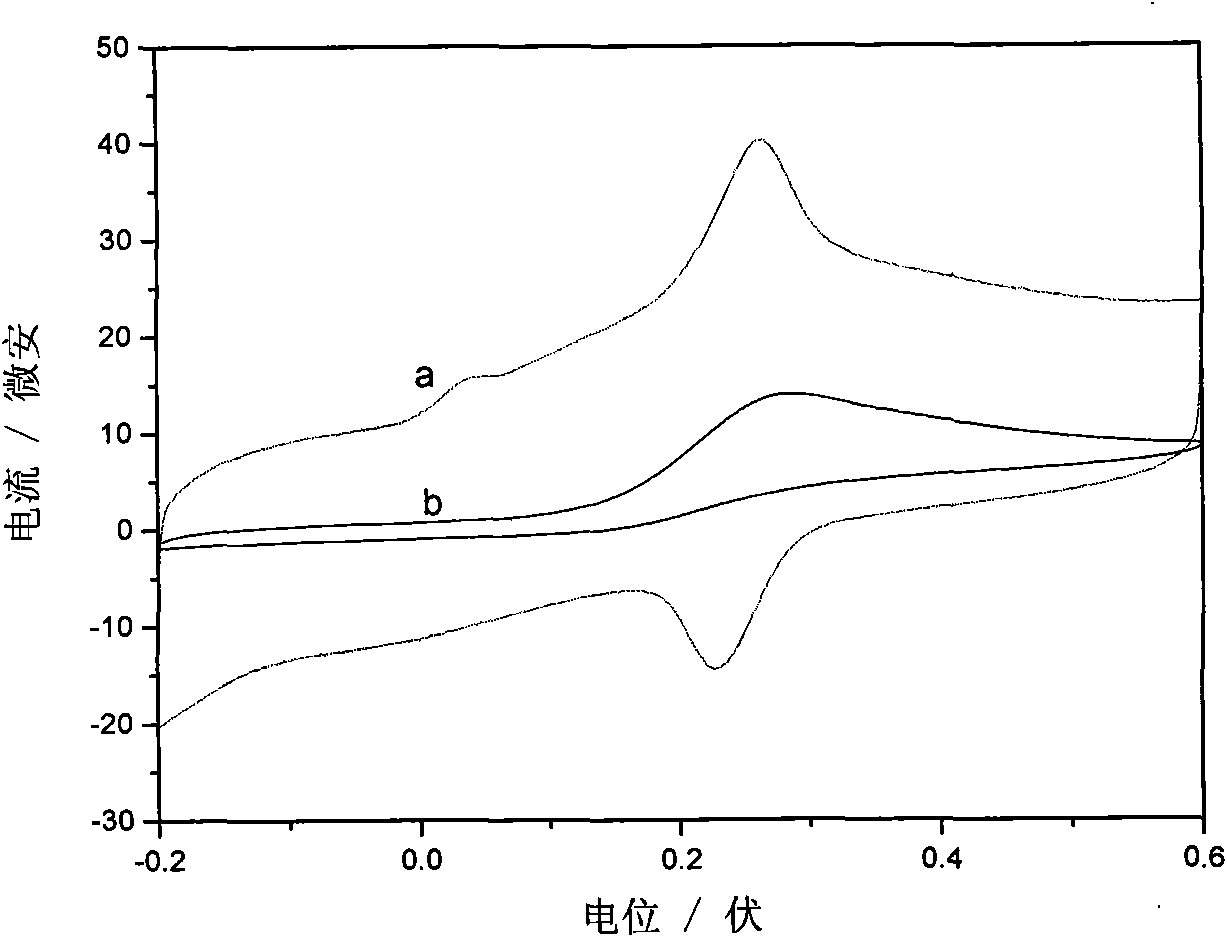

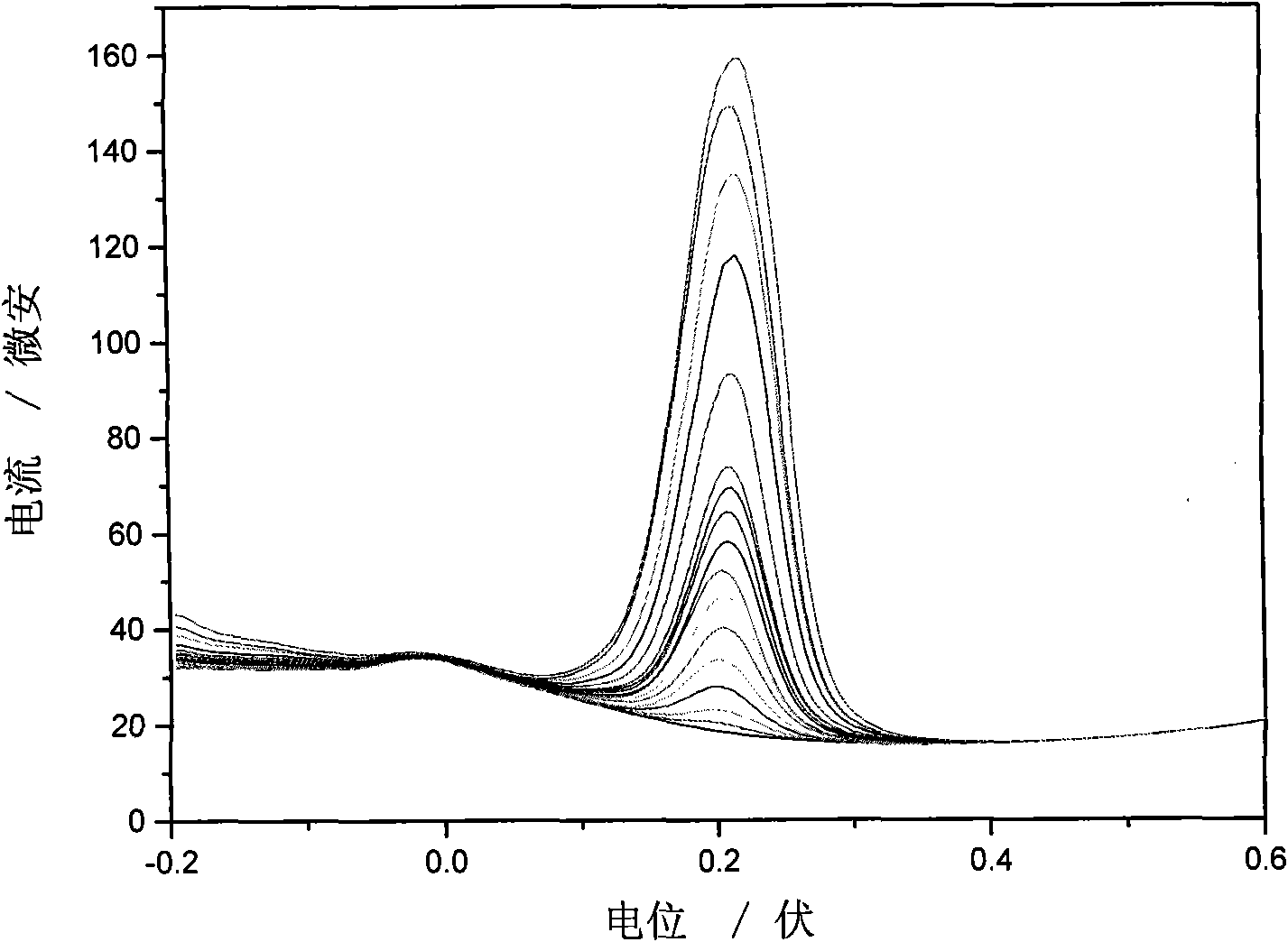

Method for measuring dopamine by utilizing graphite nano-sheet/Nafion composite film to modify electrode

A technology of graphite nanosheets and composite films, applied in the field of electrochemical analysis and detection, can solve problems such as the difficulty of chemically modifying electrodes, and achieve the effects of many surface active sites, simple preparation method and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] a. First, the glassy carbon electrode is sequentially coated with 1μm, 0.3μm, 0.05μm Al 2 o 3 The polishing powder is polished on a polishing cloth, and after each polishing, it is ultrasonically cleaned in double distilled water.

[0015] b. Prepare graphite nanosheet / Nafion mixed solution: first prepare Nafion aqueous solution, add 5% by mass Nafion solution to secondary water to dilute to obtain 0.5% by mass Nafion solution A; add graphite nanosheet to Nafion solution A to make graphite nanosheet The flake content is 7% by mass, and the black and uniformly dispersed graphite nanoflake / Nafion mixed solution B is obtained by ultrasonic shaking for 30 minutes.

[0016] c. Preparation of graphite nanosheet / Nafion composite film modified glassy carbon electrode: pipette 4 μL of the dispersion B prepared in step b with a micro-syringe and drop-coat it on the surface of the glassy carbon electrode treated in step a, and dry it at room temperature. The solvent was volatili...

Embodiment 2

[0019] a. First, the glassy carbon electrode is sequentially coated with 1μm, 0.3μm, 0.05μm Al 2 o 3 The polishing powder is polished on a polishing cloth, and after each polishing, it is ultrasonically cleaned in double distilled water.

[0020] b. Prepare graphite nanosheet / Nafion mixed solution: first prepare Nafion aqueous solution, add 5% by mass of Nafion solution to secondary water to dilute to obtain 0.9% by mass of Nafion solution A; add graphite nanosheet to Nafion solution A to make graphite nanosheet The content of flakes is 5% by mass, and the black and uniformly dispersed graphite nano flakes / Nafion mixed solution B is obtained by ultrasonic shaking for 35 minutes.

[0021] c. Preparation of graphite nanosheet / Nafion composite film modified glassy carbon electrode: pipette 6 μL of the dispersion B prepared in step b with a micro-syringe and drop-coat it on the surface of the glassy carbon electrode treated in step a, and dry it at room temperature. The solvent ...

Embodiment 3

[0024] a. First, the glassy carbon electrode is sequentially coated with 1μm, 0.3μm, 0.05μm Al 2 o 3 The polishing powder is polished on a polishing cloth, and after each polishing, it is ultrasonically cleaned in double distilled water.

[0025] b. Prepare graphite nanosheet / Nafion mixed solution: first prepare Nafion aqueous solution, add 5% by mass Nafion solution to secondary water to dilute to obtain 0.7% by mass Nafion solution A; add graphite nanosheet to Nafion solution A to make graphite nanosheet The flake content was 6% by mass, and the black and uniformly dispersed graphite nanoflake / Nafion mixed solution B was obtained by ultrasonic shaking for 35 minutes.

[0026] c. Preparation of graphite nanosheet / Nafion composite film modified glassy carbon electrode: pipette 1 μL of the dispersion B prepared in step b with a micro-syringe and drop-coat it on the surface of the glassy carbon electrode treated in step a, and dry it at room temperature. The solvent was volati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com