Ethylene absorbent and preparation method thereof

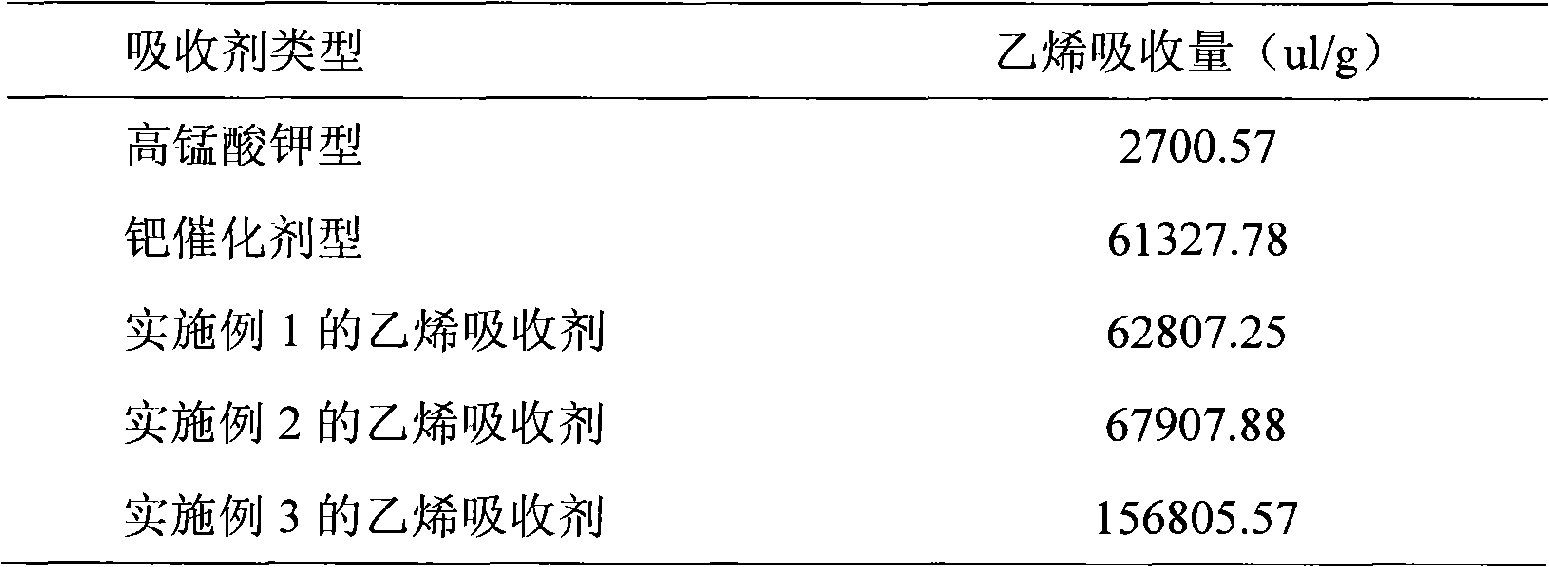

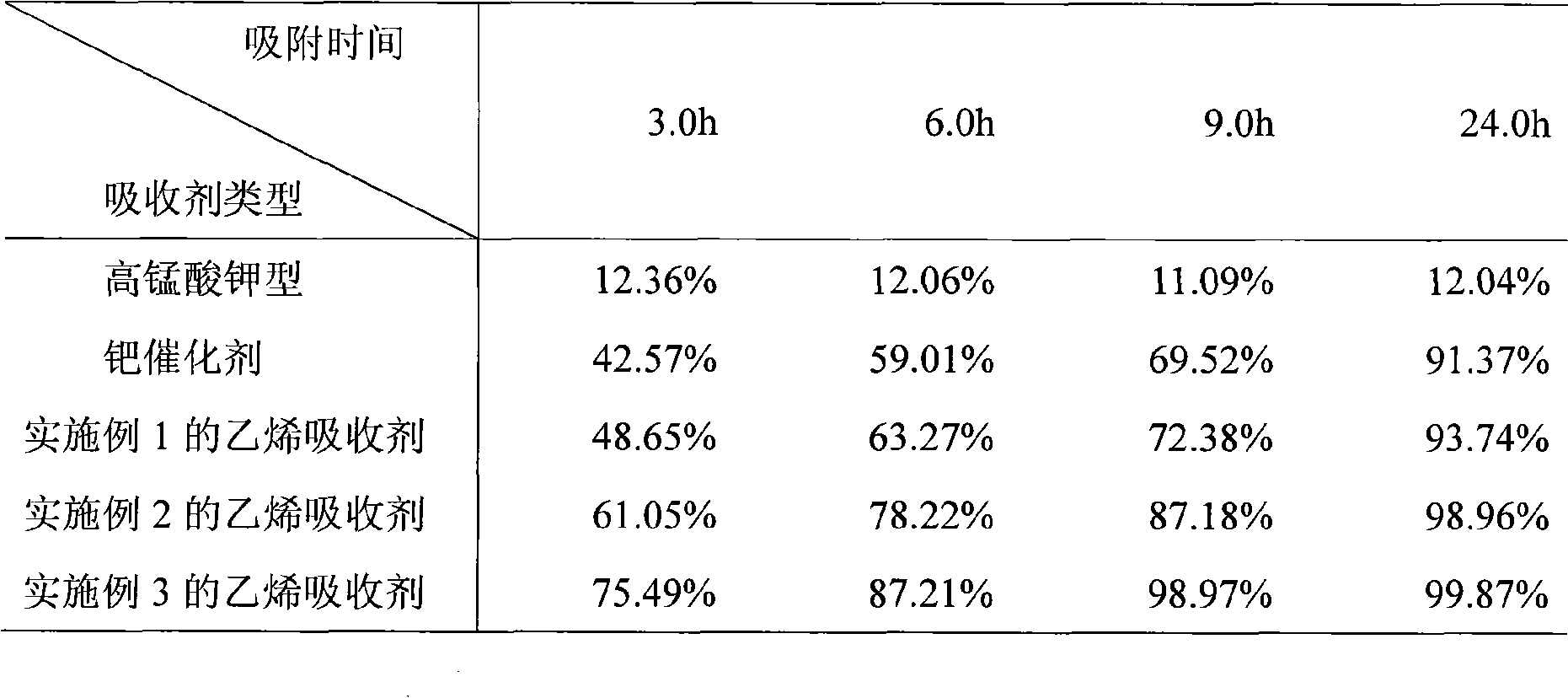

A technology of ethylene absorbent and metal additives, which is applied in the direction of botanical equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problems of operator injury, easy to corrode skin, etc., and achieve high ethylene absorption efficiency and good absorption Effect, effect of large ethylene absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An ethylene absorbent, the ethylene absorbent is prepared from a carrier substance, a metal auxiliary agent and a main reaction agent, the carrier substance is diatomite, the metal auxiliary agent is manganese chloride, and the weight of the metal auxiliary agent manganese chloride is the carrier 1% of the weight of the substance, the main reaction agent is palladium nitrate, and the weight of the main reaction agent palladium nitrate is 0.3% of the weight of the carrier substance.

[0019] The preparation method of above-mentioned ethylene absorbent, step is as follows:

[0020] (1) Weigh 20.0 g of carrier material diatomite, add 100 ml of 1mol / l nitric acid solution to acidify diatomite with nitric acid solution, stir at room temperature, acidify time is 0.5 hour, then filter or centrifuge, filter or centrifuge The final residue was dried at 60°C until the water content was 10%, to obtain an acidified diatomite carrier;

[0021] (2) Take metal additive manganese chlo...

Embodiment 2

[0025] An ethylene absorbent, the ethylene absorbent is prepared from a carrier substance, a metal auxiliary agent and a main reaction agent, the carrier substance is activated carbon, the metal auxiliary agent is anhydrous copper sulfate, and the weight of the metal auxiliary agent anhydrous copper sulfate is the carrier 3% of the weight of the substance, the main reaction agent is palladium chloride, and the weight of the main reaction agent palladium chloride is 1% of the weight of the carrier substance.

[0026] The preparation method of above-mentioned ethylene absorbent, step is as follows:

[0027] (1) Take by weighing 20.0 g of carrier material activated carbon powder, add 100 ml of 1mol / l nitric acid solution and acidify the activated carbon with nitric acid solution, stir at room temperature, and the acidification time is 5.0 hours, then filter or centrifuge, filter or centrifuge the residue in Dry at 60°C until the moisture content is 30%, to obtain acidified activa...

Embodiment 3

[0032] An ethylene absorbent, the ethylene absorbent is prepared from a carrier substance, a metal auxiliary agent and a reaction main agent, the carrier substance is artificial zeolite, the metal auxiliary agent is ammonium molybdate, and the weight of the metal auxiliary agent ammonium molybdate is the carrier substance 5% of the weight, the main reaction agent is palladium acetate, and the weight of the main reaction agent palladium acetate is 5% of the weight of the carrier substance.

[0033] The preparation method of above-mentioned ethylene absorbent, step is as follows:

[0034] (1) Weigh 20.0 g of the carrier material artificial zeolite, add 100 ml of 1mol / l nitric acid solution to acidify the artificial zeolite with nitric acid solution, stir at room temperature, and the acidification time is 10.0 hours, then filter or centrifuge, and filter or centrifuge the residue Drying at 60°C until the water content is 50% to obtain an acidified artificial zeolite carrier;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com