Artificial trachea cannula made of nano materials and preparation method thereof

A technology of artificial trachea and nanomaterials, applied in the direction of tracheal intubation, catheter, coating, etc., can solve the problems of poor lubricity and large irritation, achieve the effect of less drug dosage, high local concentration, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

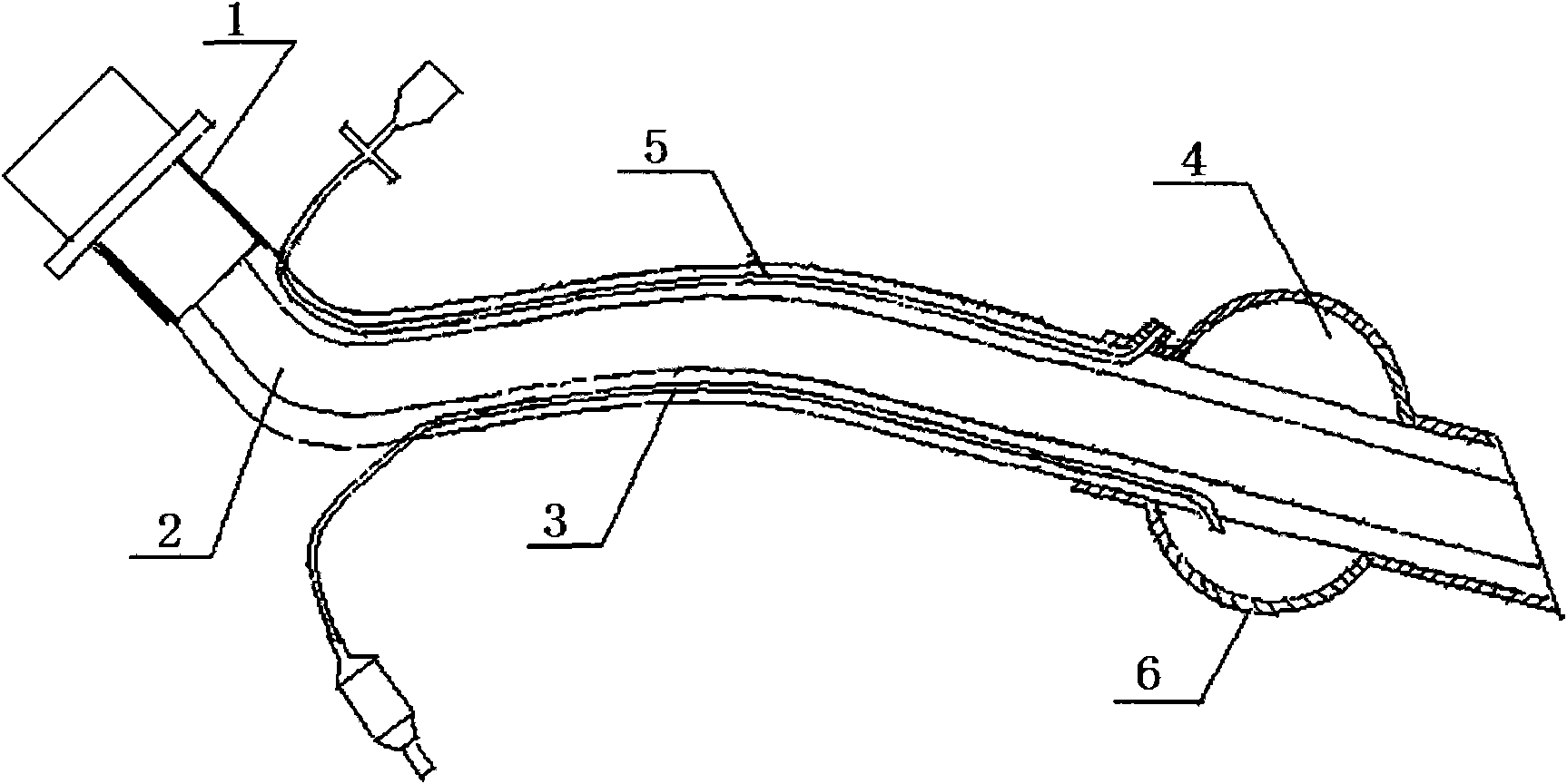

[0034] Such as figure 1 As shown, the present embodiment comprises: respirator connector 1, gas supply pipe 2, gas filling tube 3, inflatable air bag 4, liquid discharge tube 5 and lubricating coating 6, wherein: gas filling tube 3 is in the gas supply tube 2, and the gas supply tube 2 The output end is connected with the respirator connector 1, the insertion end of the trachea 2 is wedge-shaped, the outer wall of the trachea 2 is provided with an inflatable air bag 4, and the position of the inflatable air bag 4 is provided on the inflatable tube 3. 5 is inlaid on the outer wall of the air supply pipe 2 and is adjacent to the inflatable air bag 4, and the end of the liquid discharge pipe 5 close to the inflatable air bag 4 is provided with a liquid discharge port, and the other end of the liquid discharge pipe 5 is connected to the syringe. The outer wall of 2 is provided with lubricating coating 6.

[0035] This embodiment is prepared in the following ways:

[0036] The fi...

Embodiment 2

[0040] Embodiment 2: the present embodiment prepares and obtains such as by following way figure 1 Antimicrobial-lubricated artificial endotracheal tubes with composite nanomaterials shown:

[0041] The first step, with 3000g medical grade polyvinyl chloride (PVC), 15g nano-silver antibacterial material, 15g nano-zinc oxide, 60g piperacillin / tazobactam compound preparation, 1200g DINCH (BASF, HexamollDINCH), 30g stearic acid Calcium, 150g rare earth stabilizer, 450g polyvinyl acetate are fully and evenly mixed in a clean high-speed mixer;

[0042] The second step is to knead into flakes with a double-roll mill at a temperature of 160-180°C, and cut into pellets with a pelletizer to obtain medical antibacterial plastic masterbatches;

[0043] The third step is to use a twin-screw extruder to extrude the die head, plasticize and extrude the antibacterial plastic masterbatch, cool and shape it in a vacuum cooler, and then draw, cut and assemble the pipe to prepare Antibacterial...

Embodiment 3

[0045] Embodiment 3: the present embodiment prepares and obtains as follows figure 1 Antimicrobial-lubricated artificial endotracheal tubes with composite nanomaterials shown:

[0046] The first step, 3000g medical grade polyvinyl chloride (PVC), 120g nano-silver copper antibacterial material, 60g nano-titanium oxide, 300g moxifloxacin, 1200g DINCH (BASF, Hexamoll DINCH), 30g calcium stearate, 150g rare earth Stabilizer, 450g polyvinyl acetate is fully and evenly mixed in a clean high-speed mixer;

[0047] The second step is to fully and evenly mix in a clean high-speed mixer, knead into flakes with a double-roll mill at a temperature of 160-180°C, and cut into pellets with a pelletizer to obtain medical antibacterial plastic masterbatches;

[0048] The third step is to compound and mix the masterbatch with 25kg of medical grade polyvinyl chloride, use a twin-screw extruder, extrude the die head, plasticize and extrude the masterbatch, and then cool and shape the masterbatch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com