Clean production method for brewing monascus vinegar

A technology for cleaner production and red yeast rice vinegar, which is applied in the field of clean production for brewing red yeast yeast vinegar, can solve the problems of long brewing time, high grain consumption, and pollution of the environment by red yeast rice vinegar, red yeast rice wine grains and vinegar residue, and the like. Improve the utilization rate of raw materials, the sour taste is soft and long, and the effect of shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

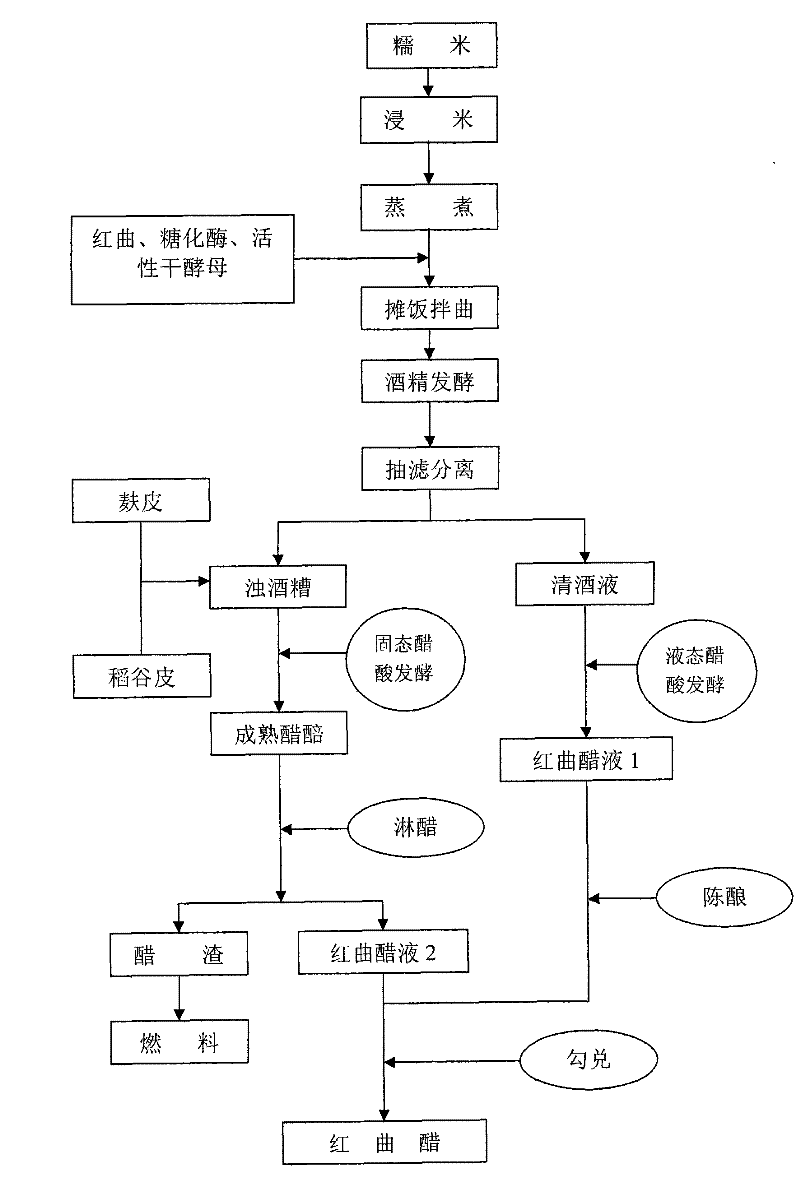

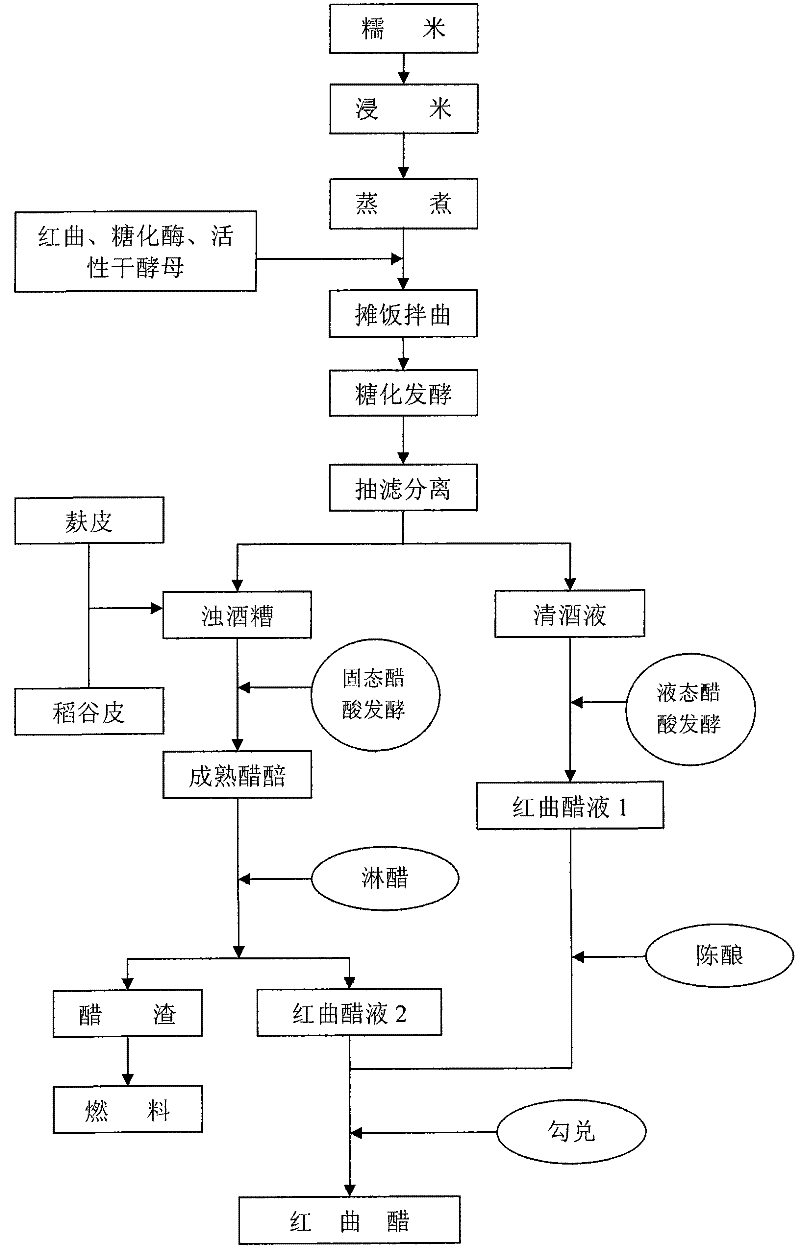

[0014] (1) Brewing red yeast rice wine: mix 1000kg glutinous rice with 200kg red yeast rice and 2.5kg glucoamylase through rice soaking, steaming, rice spreading, adding 2.0kg rice wine active dry yeast for saccharification and fermentation to produce 4800kg red yeast rice wine with an alcohol content of 10% (v / v), separated into 3240kg sake liquor and 1560kg muddy lees after suction filtration.

[0015] (2) Solid-state acetic acid fermentation and liquid acetic acid fermentation are separately fermented in parallel: 3240kg of sake liquor is fermented with liquid acetic acid to produce 5000kg of monascus vinegar 1; 1560kg of turbid distiller’s grains is added with 1400kg of rice hulls and 2500kg of bran as auxiliary materials for solid-state acetic fermentation. After 45 days of fermentation, mature vinegar is prepared. After adding monascus pigment to pour the vinegar, 3100kg of monascus vinegar liquid 2 is produced. The vinegar residue produced by leaching vinegar is dried and...

Embodiment 2

[0020] (1) Brewing of red yeast rice wine: mix 1000kg of glutinous rice with 200kg of red yeast rice and 2.5kg of glucoamylase through soaking, steaming, rice spreading, and adding 2.0kg of rice wine active dry yeast for saccharification and fermentation to produce 5000kg of red yeast wine with an alcohol content of 9.5% (v / v), separated into 3500kg sake liquor and 1500kg muddy lees after suction filtration.

[0021] (2) Solid acetic acid fermentation and liquid acetic acid fermentation are separately fermented in parallel: 3500kg of sake liquor is fermented with liquid acetic acid to produce 5000kg of monascus vinegar 1; 1500kg of turbid distiller’s grains is added with 1200kg of rice hulls and 2400kgkg of bran as auxiliary raw materials for solid acetic acid fermentation. After 60 days of fermentation, mature vinegar is obtained. After adding monascus pigment to pour the vinegar, 3100kg of monascus vinegar liquid 2 is produced. The vinegar residue produced by leaching vinegar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com