Magnetic head gimbal assembly, manufacturing method thereof and disk drive unit

A magnetic head and foldable technology, which is applied to align the tracks on the magnetic disk, magnetic recording, and maintain the alignment of the head frame, etc., can solve the problems of difficult welding, long process time, difficult installation and operation, etc. The effect of shortened process time and easy operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

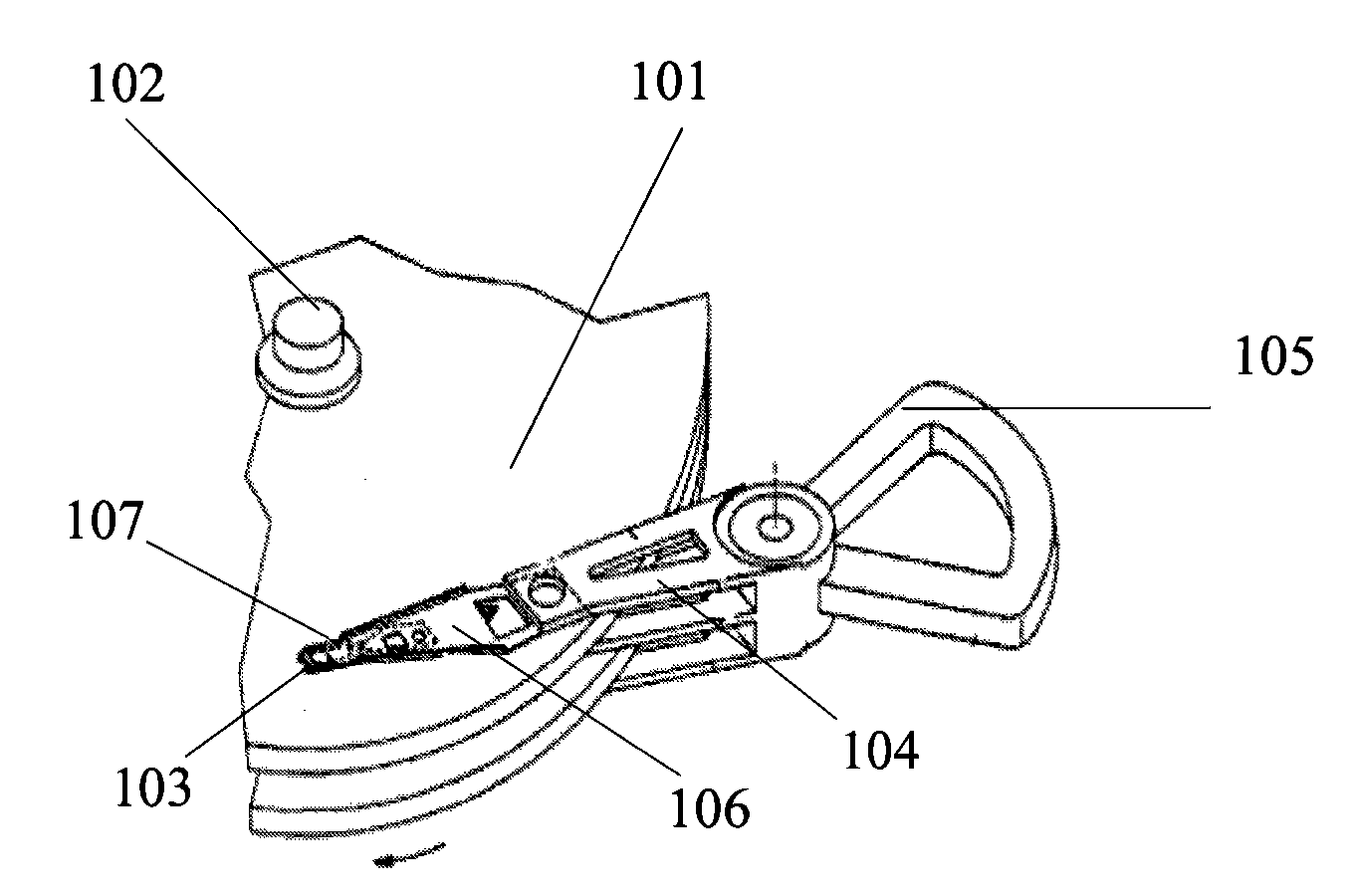

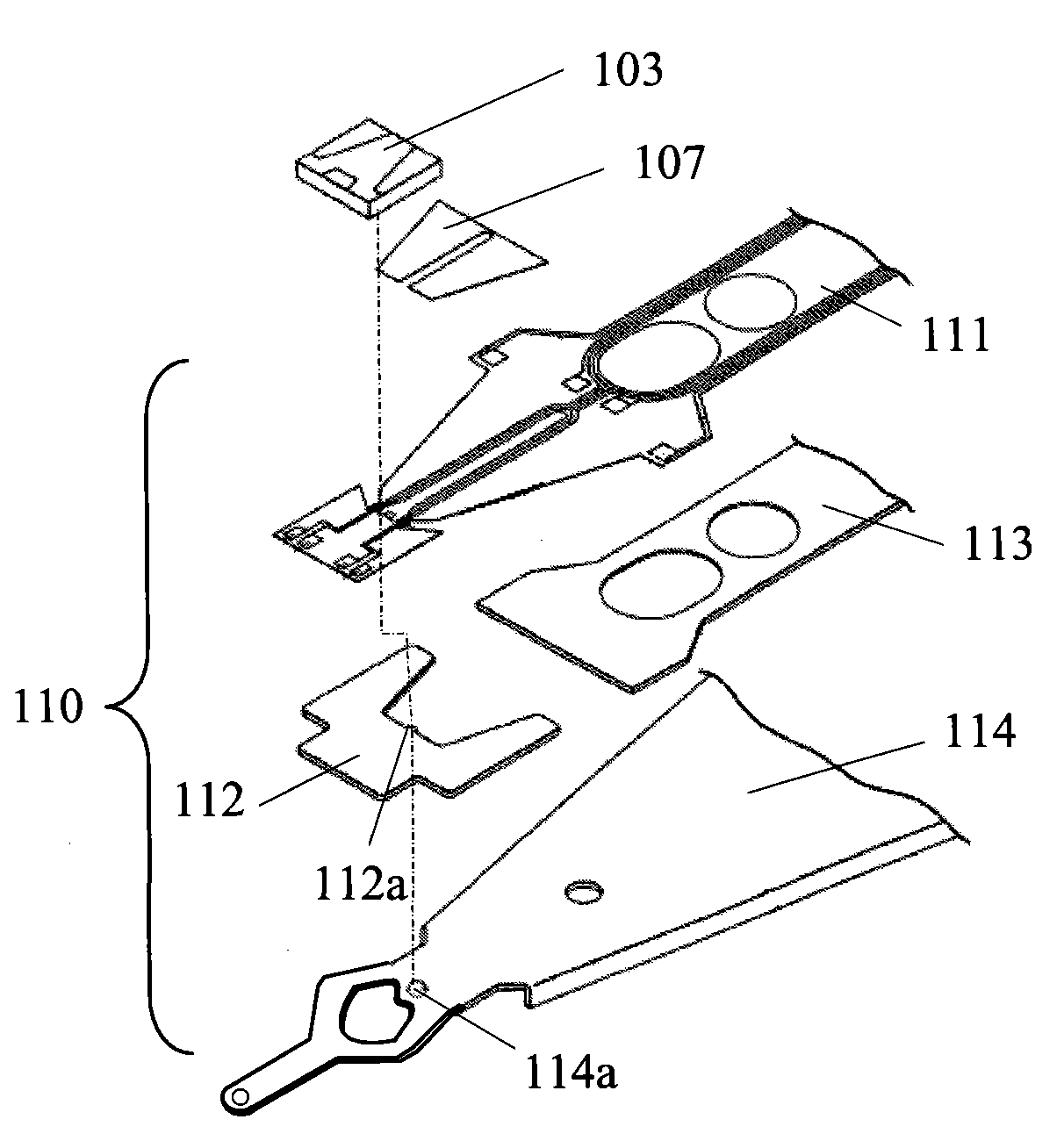

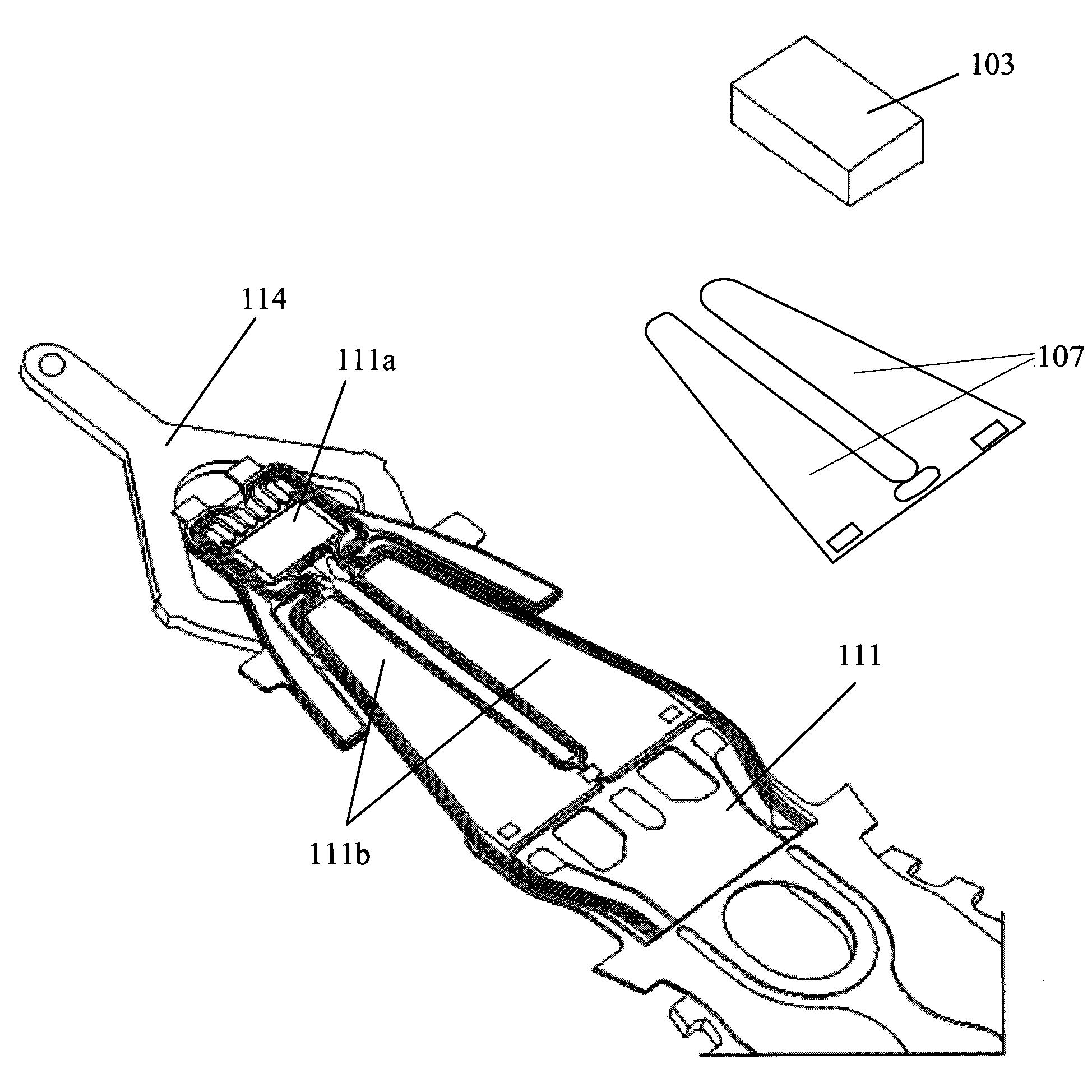

[0064] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention aims to provide a HGA and its manufacturing method, Figure 2a-9 A first embodiment of the HGA 300 of the present invention is described. see Figure 2a-2b , the HGA 300 mainly includes a magnetic head 310 , a suspension 330 carrying the magnetic head, and a micro-actuator 320 formed on the suspension 330 with a piezoelectric layer. The suspension member 330 includes a load bar 430 , a base plate 530 , a pivot member 630 and a flexible member 730 connected together. In this embodiment, the flexible member 730 , the load bar 430 and the base plate 530 are integrated by laser welding. The flexure 730 provides a number of cantilevered contacts 731 which are connected to a control system. In order to transfer the load force from the load bar 430 to the magnetic head 310 smoothly and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com