Process for production of polycarbonate resin

A technology of polycarbonate resin and preparation device, applied in the field of preparation of polycarbonate resin, can solve the problems not mentioned, etc., and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

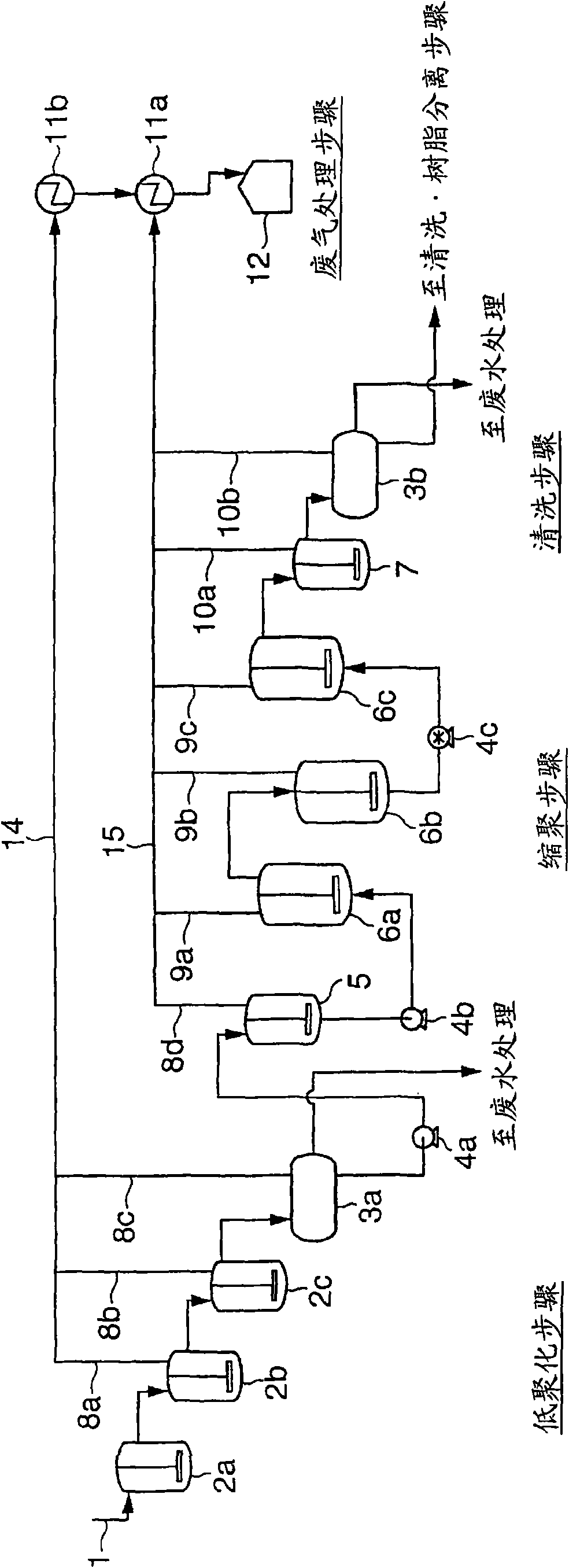

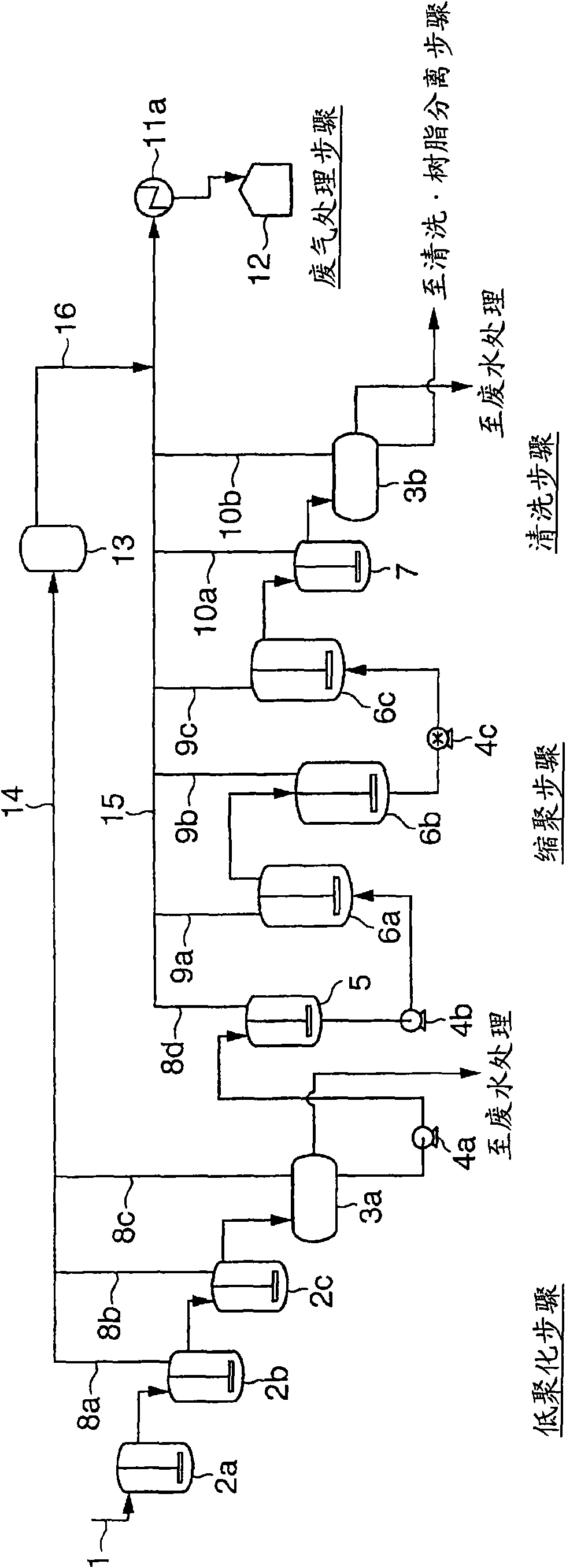

[0061] attached figure 1 and figure 2 Each is an explanatory diagram of an example of a production apparatus preferably used in the production method of the present invention. Among them, an example is given below for illustration. In this example, "BPA" is used as the dihydroxy compound, "sodium hydroxide" is used as the alkali metal compound, "dichloromethane" is used as the organic solvent, and "triethylamine" is used as the organic solvent. As a catalyst, "p-tert-butylphenol" is used as a chain terminator.

[0062] The sodium hydroxide aqueous solution of BPA, dichloromethane and liquefied phosgene supplied from the raw material supply pipe (1) pass through the oligomerization tanks (2a), (2b), and (2c) to form low carbonate with a viscosity average molecular weight of 5000 or less. Polymer. At this time, triethylamine and p-tert-butylphenol were added to the central oligomerization tank (2b) (supply piping is not shown). After the dichloromethane solution of the obta...

Embodiment 1

[0078] Using "BPA" as the dihydroxy compound, sodium hydroxide (NaOH) as the alkali metal compound, methylene chloride as the organic solvent, triethylamine (TEA) as the catalyst, and p-tert-butylphenol (pTBP) as the chain terminator, adopt The conditions shown in the table below, using the figure 2 The production apparatus shown continuously produces polycarbonate resin.

[0079] [Table 1]

[0080] BPA

kg / hr

16.0

NaOH

kg / hr

5.97

desalinated water

kg / hr

101.1

kg / hr

8.81

kg / hr

60.5

2% by weight TEA

kg / hr

0.27

24 wt% pTBP

kg / hr

1.90

Internal temperature of oligomerization tank (2a)

℃

45

Internal pressure of oligomerization tank (2a)

MPa-G

0.1

Internal temperature of oligomerization tank (2b) / (2c)

℃

30

Add 2% by weight of TEA to the oligomer storage tank (5)

kg / hr

...

Embodiment 2

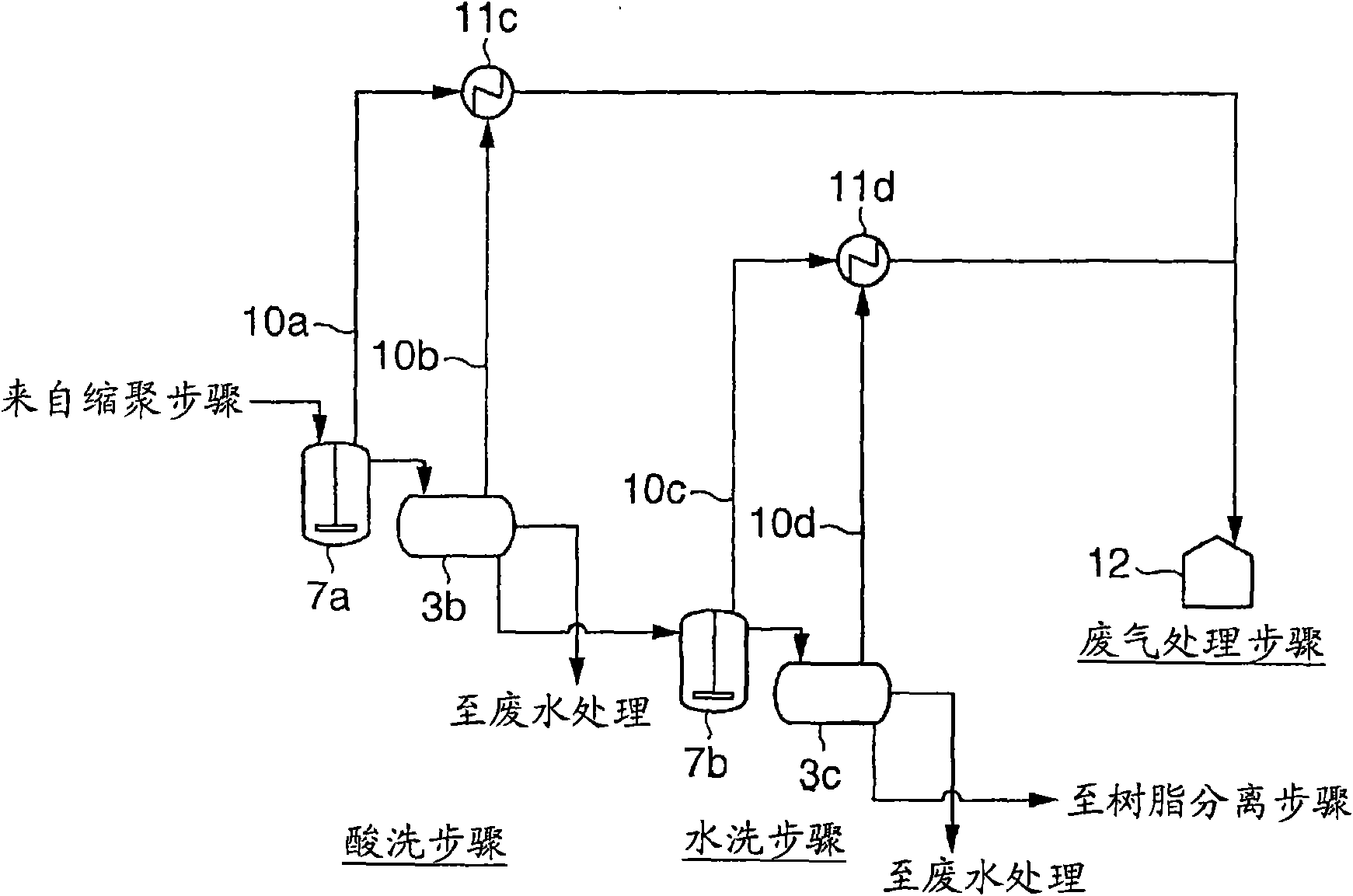

[0086] In addition to making the exhaust pipe connected to the pickling step and the exhaust pipe connected to the water washing step in embodiment 1 independent of each other (such as image 3 Shown) except, adopt the method identical with embodiment 1 to prepare polycarbonate resin continuously. Same as Example 1, the chlorine atom content from the chloroformate group is below 1 weight ppm, no abnormal batches occur, and the product quality is stable. In addition, the measured value of the free chlorine content in the resin measured by ion chromatography was stable at 10 ppb. In addition, as in Example 1, as a result of observing whether or not roll contamination occurred during film formation to produce a sheet: no roll contamination occurred at all.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com