Polylol-in-oil composition with high vitamin C content and preparation method thereof

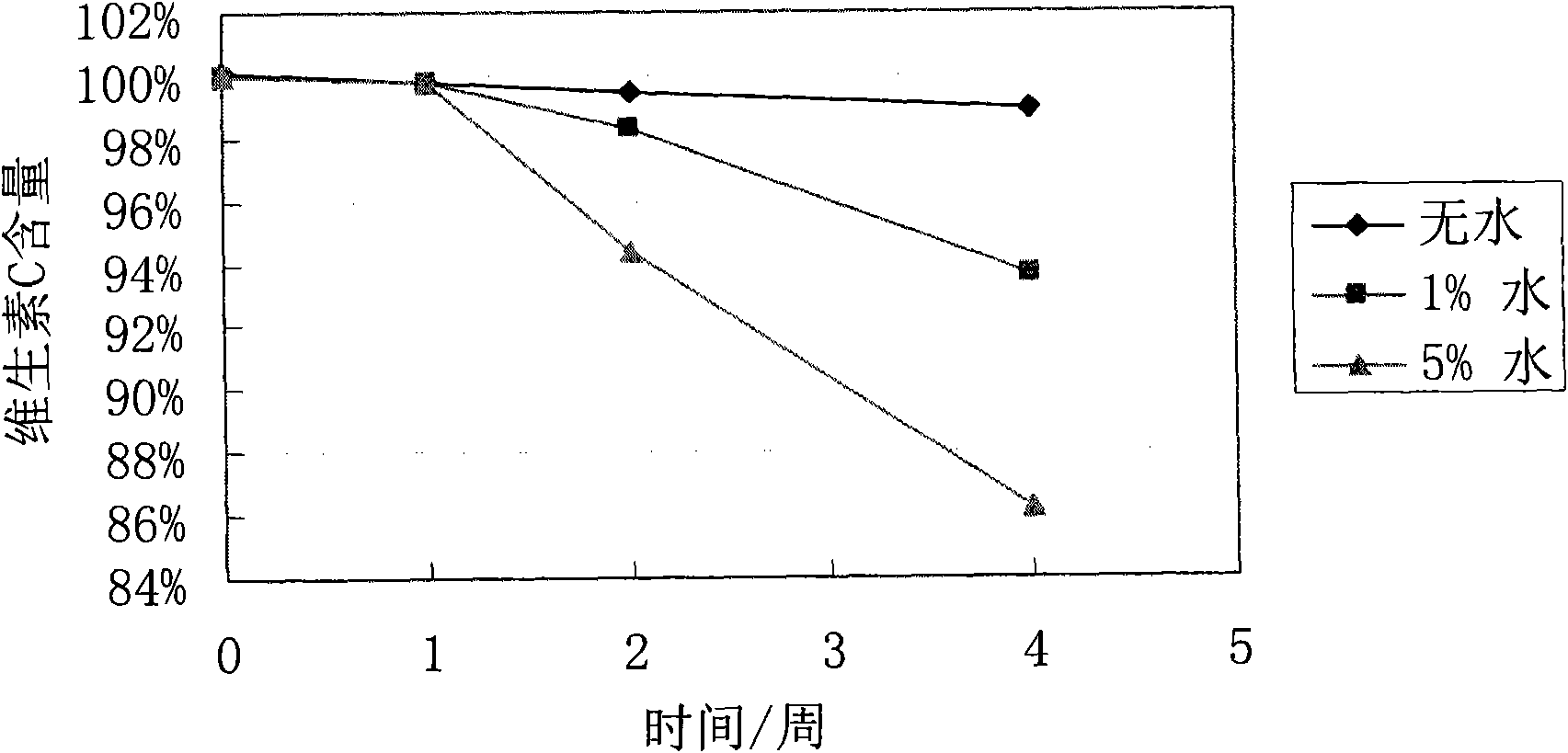

A technology of polyol-in-oil and composition, which is applied in the field of polyol-in-oil system with high vitamin C content and its preparation, and can solve the problems of easy oxidative denaturation of vitamin C and poor storage stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

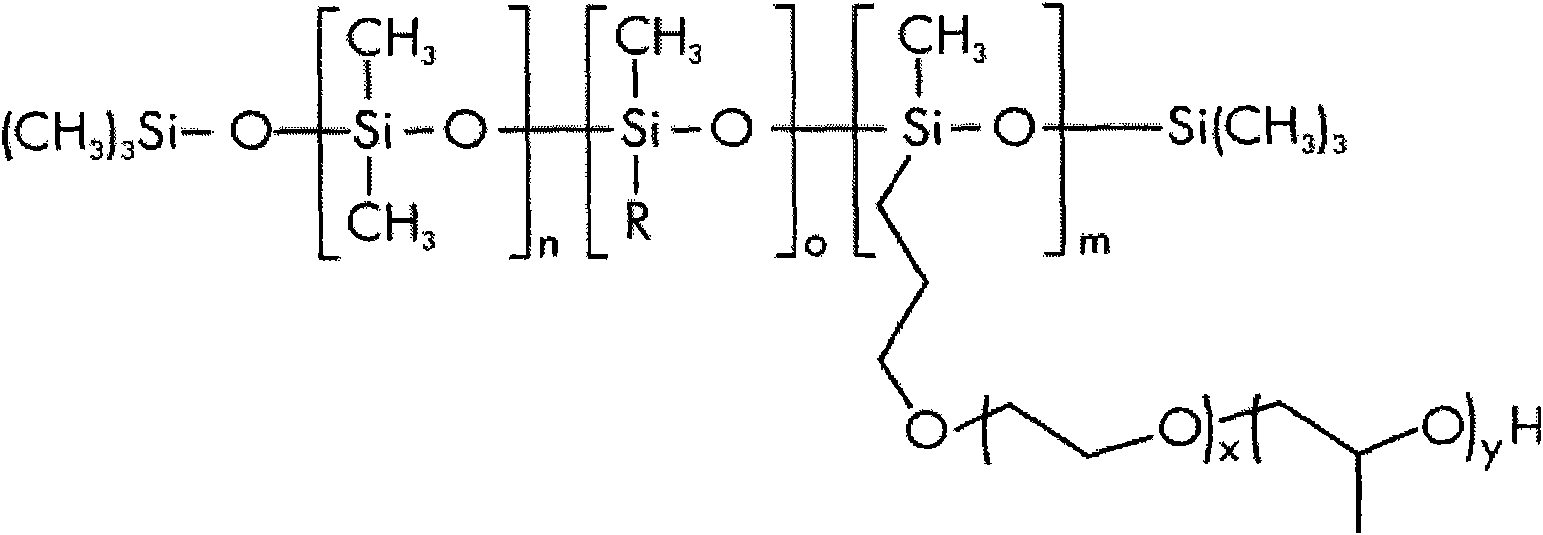

Method used

Image

Examples

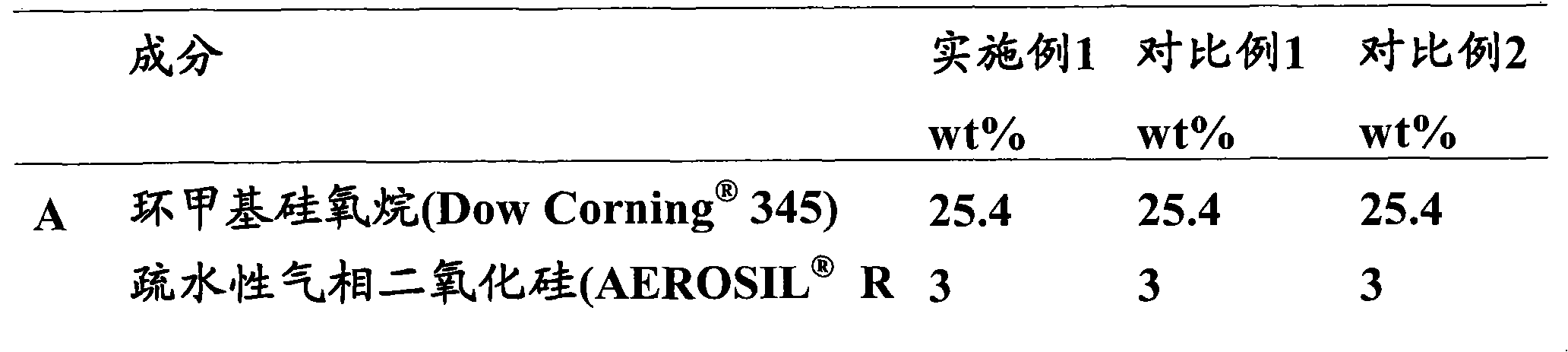

Embodiment 1 and comparative example 1 and 2

[0025]

[0026]

[0027] The preparation of the composition of embodiment 1 is carried out as follows:

[0028] 1. Will be made of 25.4wt% cyclomethicone (Dow 345) and 5.5wt% dimethylsiloxane ( 350) composition of the oil phase component, 3wt% emulsifier EM 90 and 3wt% stabilizer R 812S Mix and stir at 20-30°C until homogeneous;

[0029] 2. Add 10.5wt% solid vitamin C to the polyol component composed of 45wt% glycerin and 7.6wt% propylene glycol, heat to 90-100°C and keep for 30-45 minutes until the vitamin C is completely dissolved to form a transparent liquid; then Cool to room temperature.

[0030] 3. Add the vitamin C-containing polyol mixture obtained in step 2 to the mixture obtained in step 1 under stirring at 400-600rpm; then increase the stirring speed to 1000-16000rpm for homogenization to a homogeneous phase, that is, to obtain high vitamin C content polyol-in-oil system.

[0031] The compositions of Comparative Examples 1 and 2 were prepared similar...

Embodiment 2

[0036]

[0037] The formula has shown very good stability after four months of heat resistance at 45°C and one month of cold resistance at -25°C and a centrifugation test at 3000rpm for 30 minutes.

Embodiment 3-4

[0039]

[0040]

[0041] In embodiment 3, adopt polyglycerol-4 diisostearate / polyhydroxystearate sebacate ( GPS) and polyglyceryl-4 stearate ( GI 34) The emulsifier formed by mixing can also form a good stable system. Likewise, adopt diisostearyl polyglycerol-3 dimerized bis-linoleate in embodiment 4 ( PDI) and polyglyceryl-4 stearate ( GI 34) mixed emulsifier, the obtained product also has bright appearance and stable storage effect.

[0042] The preparation methods of Examples 2-4 are carried out with reference to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com