Processing system and processing method for purifying sewerage sludge filtrate

A purification treatment and sewage sludge technology, applied in biological water/sewage treatment, degassed water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems that microorganisms cannot purify sewage and prolong sewage purification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

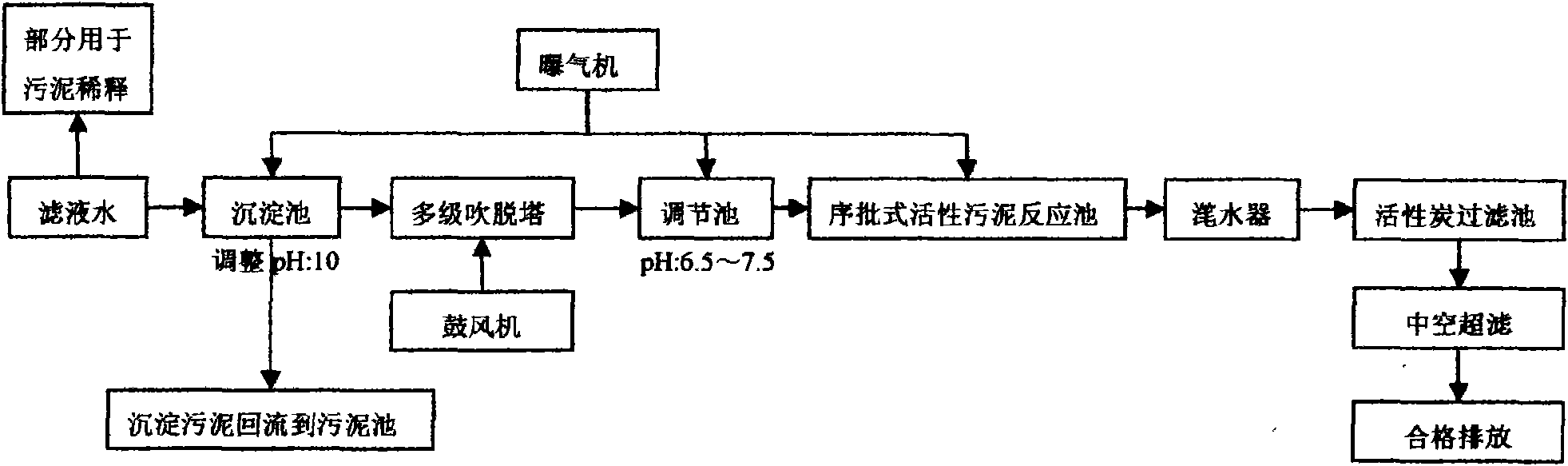

[0037] Such as figure 1 As shown, the sewage sludge filtrate purification treatment system includes successively connected sedimentation tanks, multi-stage stripping towers, adjustment tanks, sequencing batch activated sludge reaction tanks, ceramsite filter tanks, hollow ultrafiltration treatment devices, and also includes The aerator connected to the sedimentation tank, multi-stage stripping tower, regulating tank and sequencing batch activated sludge reaction tank, the sludge tank connected to the sedimentation tank, and the decanter installed in the sequencing batch activated sludge reaction tank , the multi-stage stripping tower includes a blower.

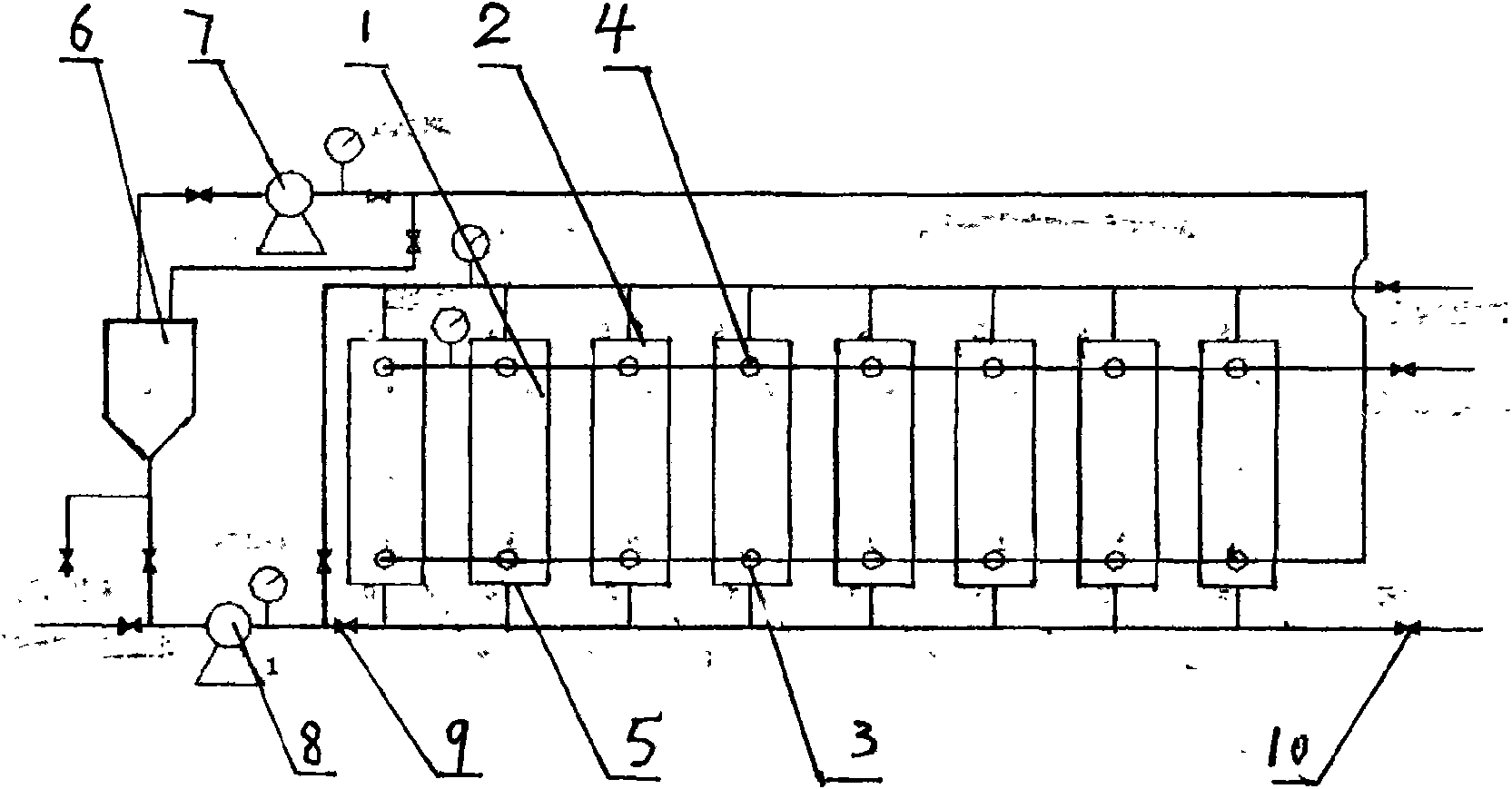

[0038] Such as figure 2 As shown, the hollow ultrafiltration treatment device includes two or more storage pipes 1, a hollow fiber membrane (not shown) integrated in the storage pipe 1, and each storage pipe 1 is provided with a filtrate inlet 2, The sewage outlet 5, the purified water outlet 3, 4, the filtrate inlet 2 of t...

Embodiment 2

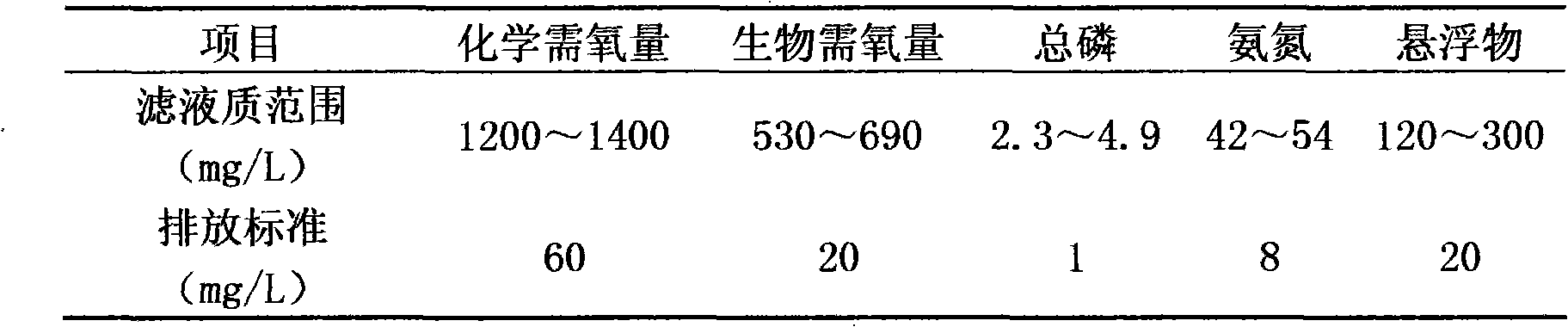

[0041] The sedimentation tank is 15 meters long, 3 meters wide, effective depth is 2 meters, and the residence time is 2 hours. After the filtrate water passes through the sedimentation tank for aeration and sedimentation, most of the sludge particles that have passed through the filter holes of the filter cloth at the beginning of the press filtration are removed from the water. After sedimentation, the sludge pump is discharged into the sludge tank; the average effluent water quality of the sedimentation tank: the chemical oxygen demand is about 1170mg·L -1 , the biological oxygen demand is 570mg·L -1 , the suspended matter is 160mg·L -1 , the removal efficiency of total phosphorus and ammonia nitrogen is not obvious.

[0042] The effluent of the sedimentation tank is transported by the sewage pump to the air stripping tower to remove ammonia nitrogen, and the pH value is adjusted to about 10 with lime. The sewage enters from the top and sprays downward, collides with the f...

Embodiment 3

[0048] The difference with embodiment 2 is:

[0049] The residence time of the filtrate in the sedimentation tank is 1.5 hours. The average effluent quality of the sedimentation tank: the chemical oxygen demand is about 950mg·L -1 , the biological oxygen demand is 494mg·L -1 , the suspended matter is 150mg·L -1 , the removal efficiency of total phosphorus and ammonia nitrogen is not obvious.

[0050] Adjust the pH to about 9.5 with lime. The residence time in the stripping tower is 1 hour, the water temperature is heated to 60°C, and the gas-water ratio is 2000-2500m 3 / m 3 , the ammonia nitrogen removal rate of the stripping tower can reach 48%, and the average effluent concentration of ammonia nitrogen is about 20.1mg·L -1 .

[0051] Adjust the pH in the adjustment tank to 6.5; the residence time in the adjustment tank is 3 hours; the average chemical oxygen demand of the effluent in the adjustment tank is 800mg·L -1 , the biological oxygen demand is 420mg·L -1 , am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com