Method for preparing poly(pseudo)rotaxanes with gamma-cyclodextrin and polyvinyl alcohol

A technology of polyvinyl alcohol and quasi-polyrotaxane, which is applied in the field of new polymer material preparation, can solve problems such as unreported, and achieve the effects of good water solubility, simple preparation process and broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Preparation of polyvinyl alcohol: 50ml of vinyl acetate was added to 250ml of methanol, 1.2g of azobisisobutyronitrile was added, the weight ratio of azobisisobutyronitrile to vinyl acetate was 0.026:1, and nitrogen was blown to remove After oxygen, put it into a constant temperature water bath with a temperature of 65°C under the protection of nitrogen, and polymerize for 6 hours to obtain polyvinyl acetate; use a rotary evaporator to evaporate the unreacted vinyl acetate monomer at 40°C under reduced pressure; The solution of polyvinyl acetate was transferred to a 250mL three-neck flask equipped with a stirrer and a thermometer, and 2.0mL of NaOH solution with a concentration of 10mol / L was added dropwise, and the molar ratio of the NaOH solution added dropwise to vinyl acetate was 0.037:1. Then alcoholyze in a water bath with a temperature of 35°C for 1.5 hours; the product after alcoholysis is centrifuged at a high speed of 11000r / min, and the solid powder obtaine...

Embodiment 2

[0028] 1) Preparation of polyvinyl alcohol: add 50ml of vinyl acetate to 472ml of methanol, add 1.7g of azobisisobutyronitrile, the weight ratio of azobisisobutyronitrile to vinyl acetate is 0.037:1, blow nitrogen to remove After oxygen, put it in a constant temperature water bath with a temperature of 65°C under the protection of nitrogen, and polymerize for 8 hours to obtain polyvinyl acetate; use a rotary evaporator to evaporate the unreacted vinyl acetate monomer at 40°C under reduced pressure; The solution of polyvinyl acetate was transferred to a 250mL three-necked flask equipped with a stirrer and a thermometer, and 0.9mL of a 10mol / L NaOH solution was added dropwise. The molar ratio of the added NaOH solution to vinyl acetate was 0.017:1, and then Alcoholysis in a water bath at 40°C for 2 hours; the product after alcoholysis was centrifuged at a high speed of 11000r / min, and the solid powder obtained after centrifugation was washed twice with methanol; then dissolved in...

Embodiment 3

[0032] 1) Preparation of polyvinyl alcohol: the same as in Example 1.

[0033] 2) Preparation of pseudopolyrotaxane: Dissolve 2.0g of polyvinyl alcohol in 20ml of deionized water and stir until completely dissolved at 85°C; then add 3.0g of γ-cyclodextrin solid powder, γ-cyclodextrin and polyvinyl alcohol The molar ratio is 10:1, stirred at 80°C for 80 hours; after the reaction, evaporate the reaction solution to about 5ml with a rotary evaporator, and vacuum-dry the obtained concentrated solution to obtain γ-cyclodextrin and polyethylene Alcohol pseudopolyrotaxanes.

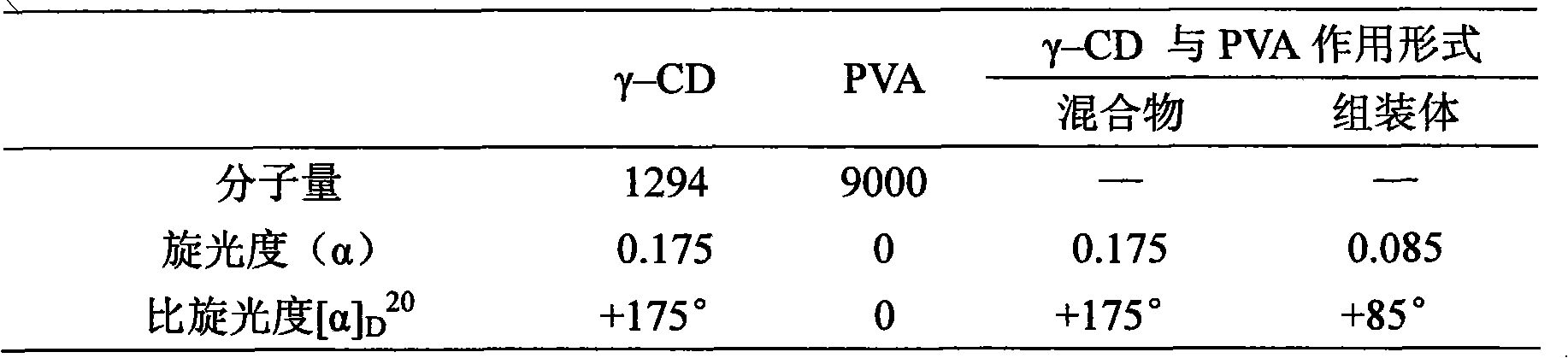

[0034] The prepared γ-cyclodextrin and polyvinyl alcohol pseudopolyrotaxane were analyzed by thermogravimetric analysis and infrared spectrum. The thermal gravimetric spectrum shows that the decomposition temperature of polyvinyl alcohol is 276°C, the thermal decomposition temperature of γ-CD is 321°C, and the thermal decomposition temperature of γ-cyclodextrin and polyvinyl alcohol pseudopolyrotaxane is 337°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com