Yeast and application thereof in the weak alkaline treatment of vegetable-pickling waste water

A technology for pickling wastewater and Candida, which is applied in the field of environmental microorganisms, can solve problems such as high cost, acidic pH of wastewater, and secondary pollution, and achieve strong salinity tolerance, good bacterial sedimentation, and reduced The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

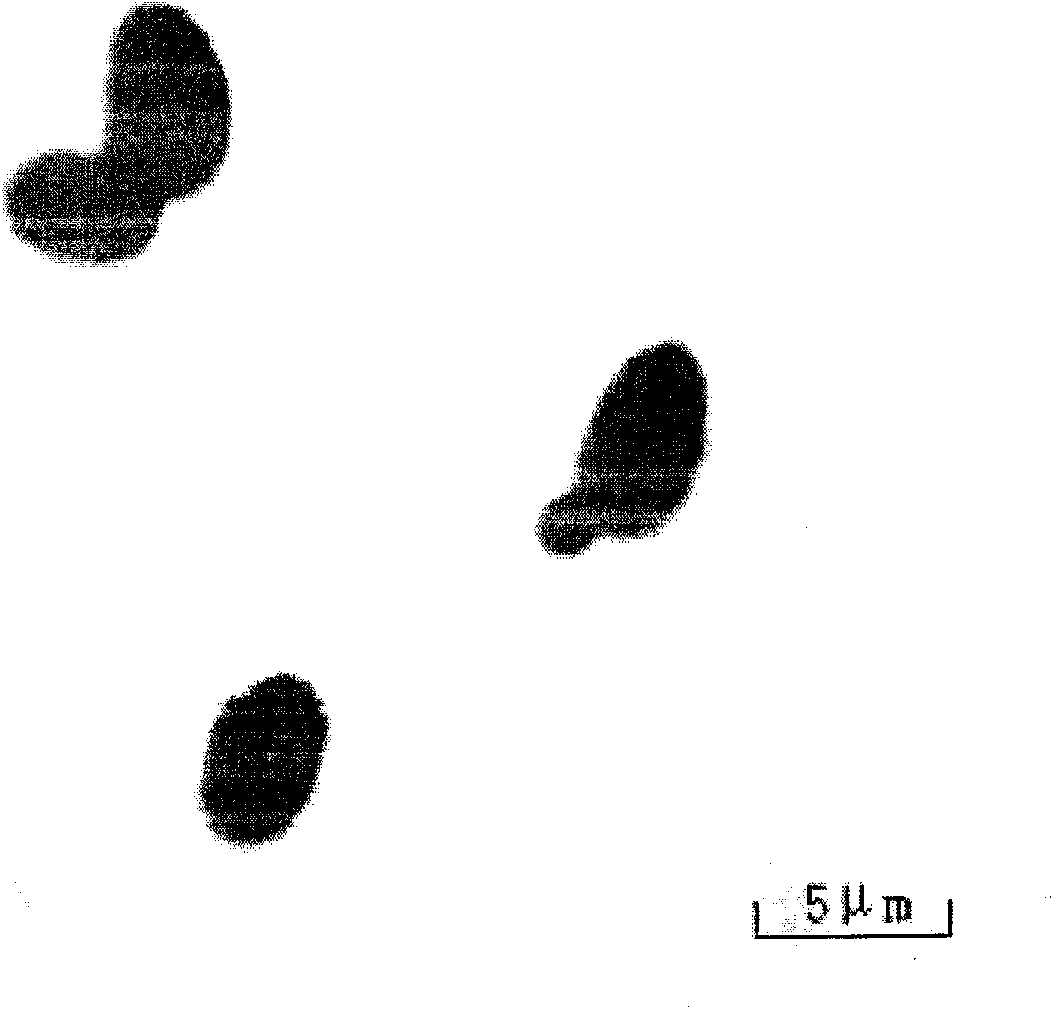

[0031] Example 1. Isolation and screening of Candida G70

[0032]Put 2g of mud sample collected from a sewage discharge outlet of a mustard plant in Cixi, Zhejiang into 50ml of filtered mustard waste water, add glass beads to shake and disperse, take 5ml of supernatant and add it to 50ml of filtered mustard waste water at a temperature of 30°C, The rotating speed was 160 rpm, and the enrichment culture was carried out on a shaker for 4 days. The enriched culture bacterial solution was diluted with the filtered and sterilized mustard wastewater, and then coated with mustard wastewater medium plate, and cultured at 30 °C for 4 days; In the mustard wastewater, the temperature was 30 °C, the rotation speed was 160rpm, and the shaking table was cultivated for 48 hours, and the strains that could alkalize the mustard wastewater were screened; the strains that could alkalize the mustard wastewater were streaked and cultured to obtain a single clone, and mustard is still used for stre...

Embodiment 2

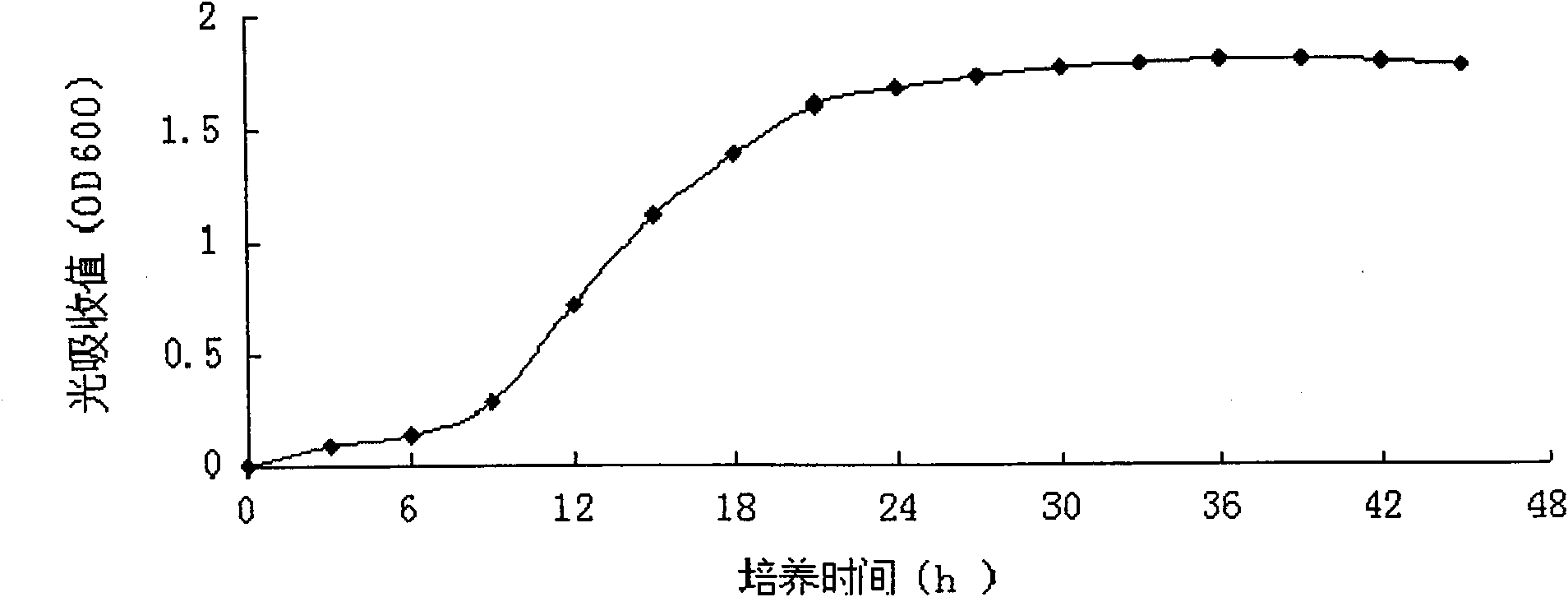

[0034] Example 2, Candida G70 growth conditions

[0035] 1) Growth temperature range: Pick Candida G70 with an inoculation loop to the slant of the malt extract powder medium (dry malt extract powder 0.3%, dry yeast powder 0.3%, peptone 0.5%, glucose 1%, agar 2%, pH Natural (about 5.5)), 30 ℃ constant temperature static culture for 24-36h, milky white bacteria appear; use the inoculation ring to pick the well-grown bacteria from the inclined surface and inoculate it into the liquid medium containing malt extract powder (dry malt extract Powder 0.3%, dry yeast powder 0.3%, peptone 0.5%, glucose 1%, pH natural (about 5.5)) in a conical flask, temperature 30 ° C, rotating speed 160 rpm, shaker culture, wait for the bacterial liquid to grow to OD 600 When it is 0.3-0.6, the inoculum amount of 2% (v / v) is transferred to fresh malt extract powder medium, and the growth temperature range of Candida G70 is determined. The temperature gradient is: 10°C, 15°C, 20°C, 25°C, 30°C, 35°C, 4...

Embodiment 3

[0039] Example 3: PCR amplification and sequence determination of the 26S rRNA gene of Candida sp. G70

[0040] Take 1ml of fresh bacterial liquid, centrifuge at 12000rpm for 1min, discard the supernatant; add 100μl of GTE solution (25mmol / L Tris-HCl (pH8.0), 10mmol / L EDTA, 50mmol / L glucose) to the precipitate, shake and mix on a vortex mixer. Homogenize until the precipitate is completely dispersed; then add 650 μl of GTE solution and mix by shaking. Then add 7.5 μl of 100 mg / ml lysozyme to the suspension to a final concentration of 1 mg / ml, mix well, and incubate at 37°C for 30 min; then add 7.5 μl of 10 mg / ml proteinase K to the suspension to a final concentration of 0.1 mg / ml, mix well, incubate at 55°C for 1 h, and invert the centrifuge tube several times. After the warm bath, add an equal volume (750 μl) of phenol / chloroform / isoamyl alcohol to the solution, invert and mix, and centrifuge at 12,000 rpm for 5 min; transfer the supernatant to a new centrifuge tube, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com