Low-Nd anisotropic Nd2Fe14B/alpha-Fe composite nanocrystalline magnet and preparation method thereof

A nd2fe14b, anisotropic technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of soft magnetic phase content limitation, unfavorable magnetic properties, and difficulty in achieving high saturation magnetization of magnets, etc. Achieve the effect of improving strength and corrosion resistance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

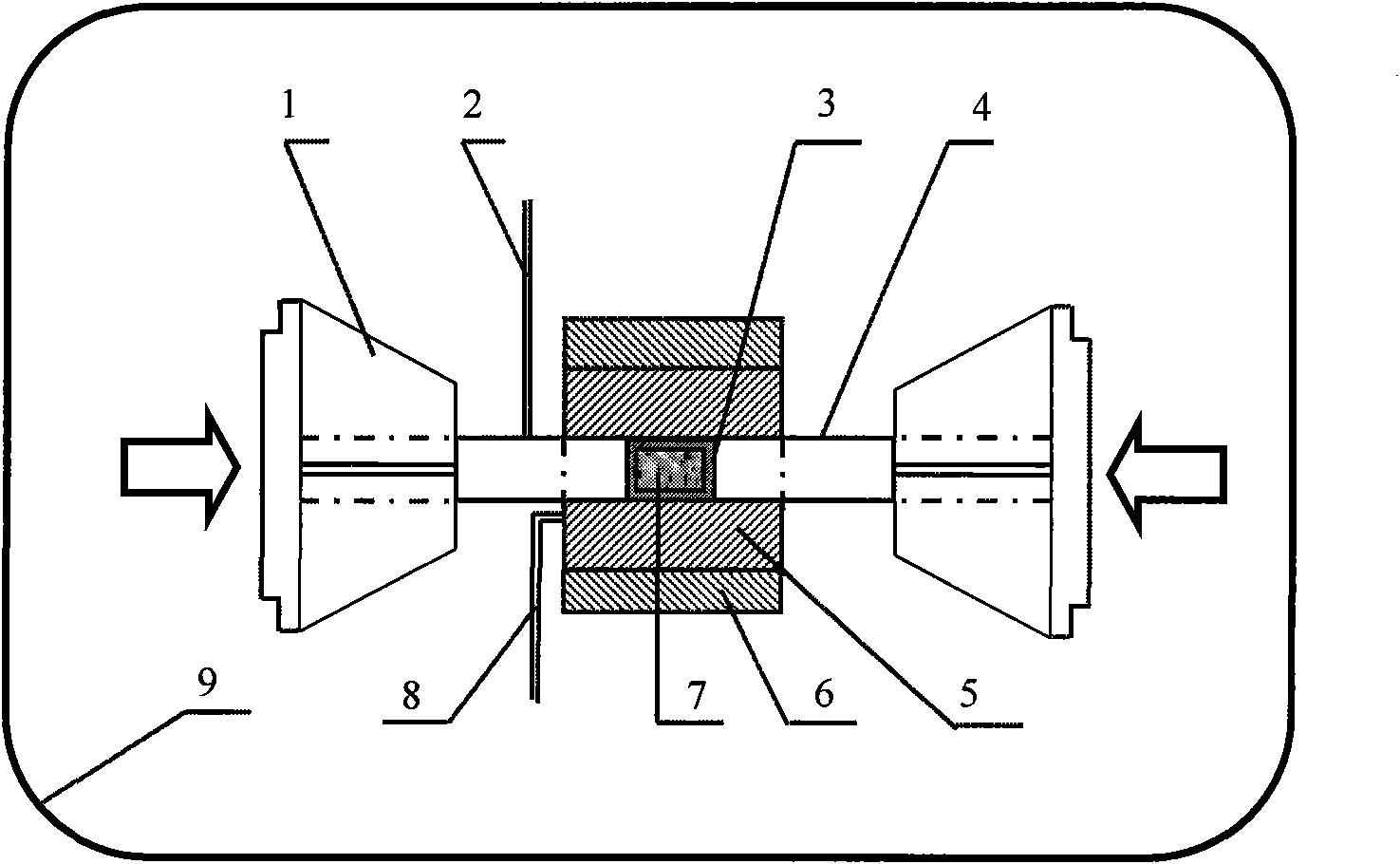

[0016] Nd 9 Fe 85 B 6 The alloy is prepared on a single-roll spinning machine at a linear speed of 40m / s to produce Nd with a width of 2mm and a thickness of about 25μm. 9 Fe 85 B 6 The amorphous ribbon is then crushed and powdered, with a particle size below 500μm. Nd 9 Fe 85 B 6 The alloy powder is loaded into the mold (e.g. figure 1 ), the mold is composed of a clamp 1, a temperature control thermoelectric corner 2, a stone black sleeve 3, a pressure head 4, an internal female mold 5, an external female mold 6 and a temperature measuring electrical corner 8. The indenter 4 is made of tungsten carbide YG19, the inner female mold 5 is made of WC, and the outer female mold 6 is made of Cr3W2V8. The female mold is composed of the inner female mold 5 and the outer female mold 6. Put the stone black sleeve 3 into the female mold, and put the Nd-Fe-B alloy powder 7 in the stone black sleeve 3, and finally put the mold in the vacuum chamber 9. Under vacuum conditions, hot press for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com