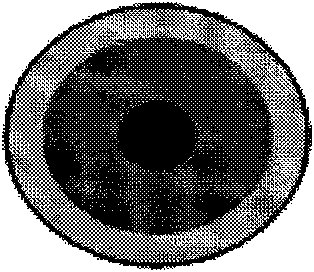

TiO2/SiO2/Fe3O4 nano particle with nuclear shell structure and manufacturing method thereof

A nanoparticle, core-shell structure technology, applied in the field of nanoparticles, can solve the problems of difficult to control recycling and low catalytic efficiency, and achieve the effect of convenient and effective control and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

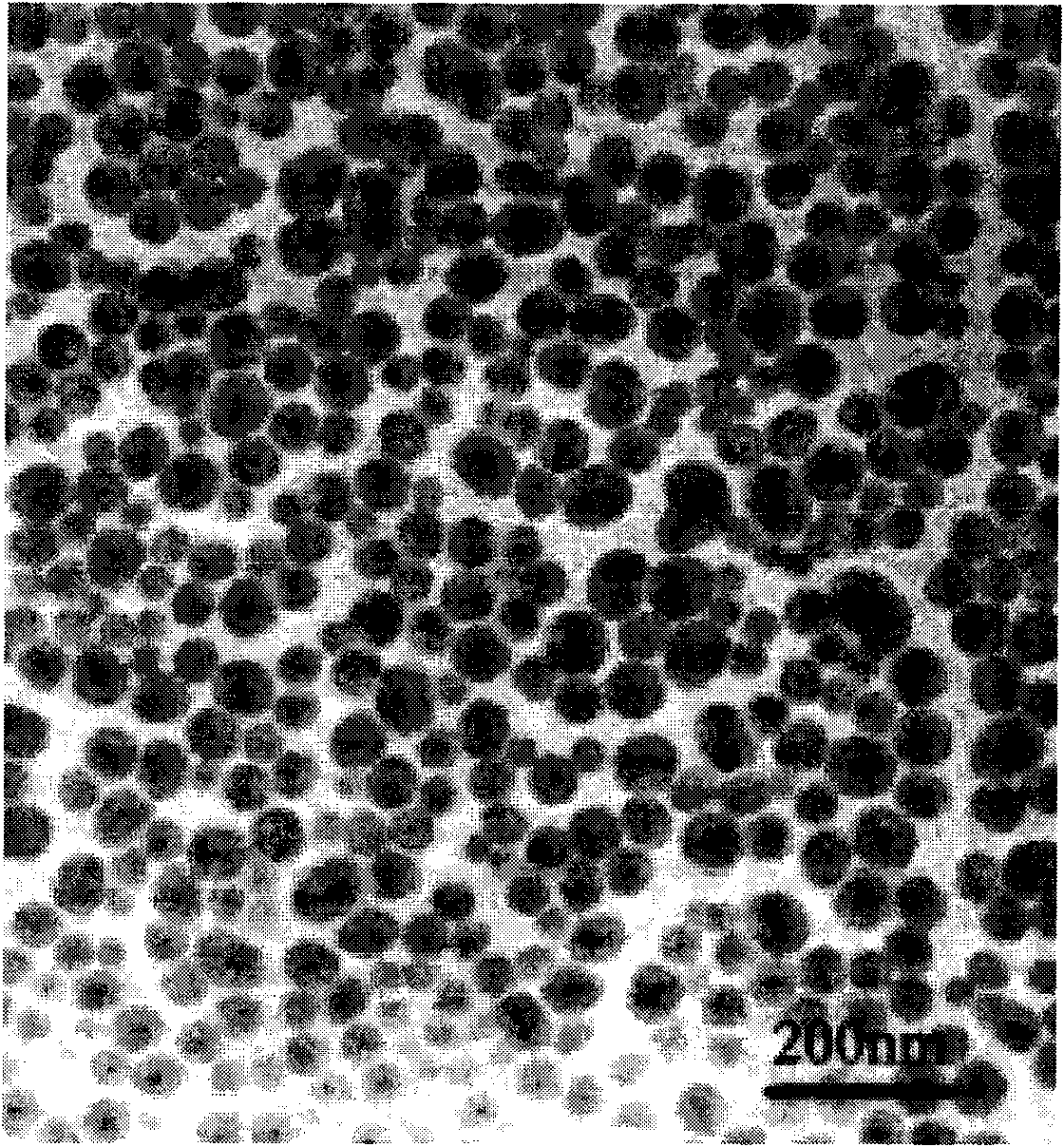

[0028] Embodiment 1, a kind of TiO with core-shell structure 2 / SiO 2 / Fe 3 o 4 A method for preparing nanoparticles, comprising the following steps:

[0029] (1) FeCl 3 .6H 2 O and FeCl 2 .4H 2 O was mixed according to the amount of substances 2:1, and Fe was synthesized under alkaline conditions by coprecipitation wet chemical method. 3 o 4 Nano-magnetic core, controlled Fe by ultrasonic dispersion during the reaction 3 o 4 Particle size, improve dispersion, and then magnetic separation and water washing;

[0030] Specifically: 16mmol of FeCl 3 .6H 2 O with 8mmol of FeCl 2 .4H 2 O was added to 190ml deionized water and magnetically stirred at room temperature, and 10ml of 25% ammonia water was added to continue stirring for 10 minutes, a black precipitate was formed, which was washed with magnetic separation and water for 3 times;

[0031] (2) to Fe 3 o 4 The particle surface is treated to make it stable in aqueous solution. Use HNO first 3 Wash 2 to 3 tim...

Embodiment 2

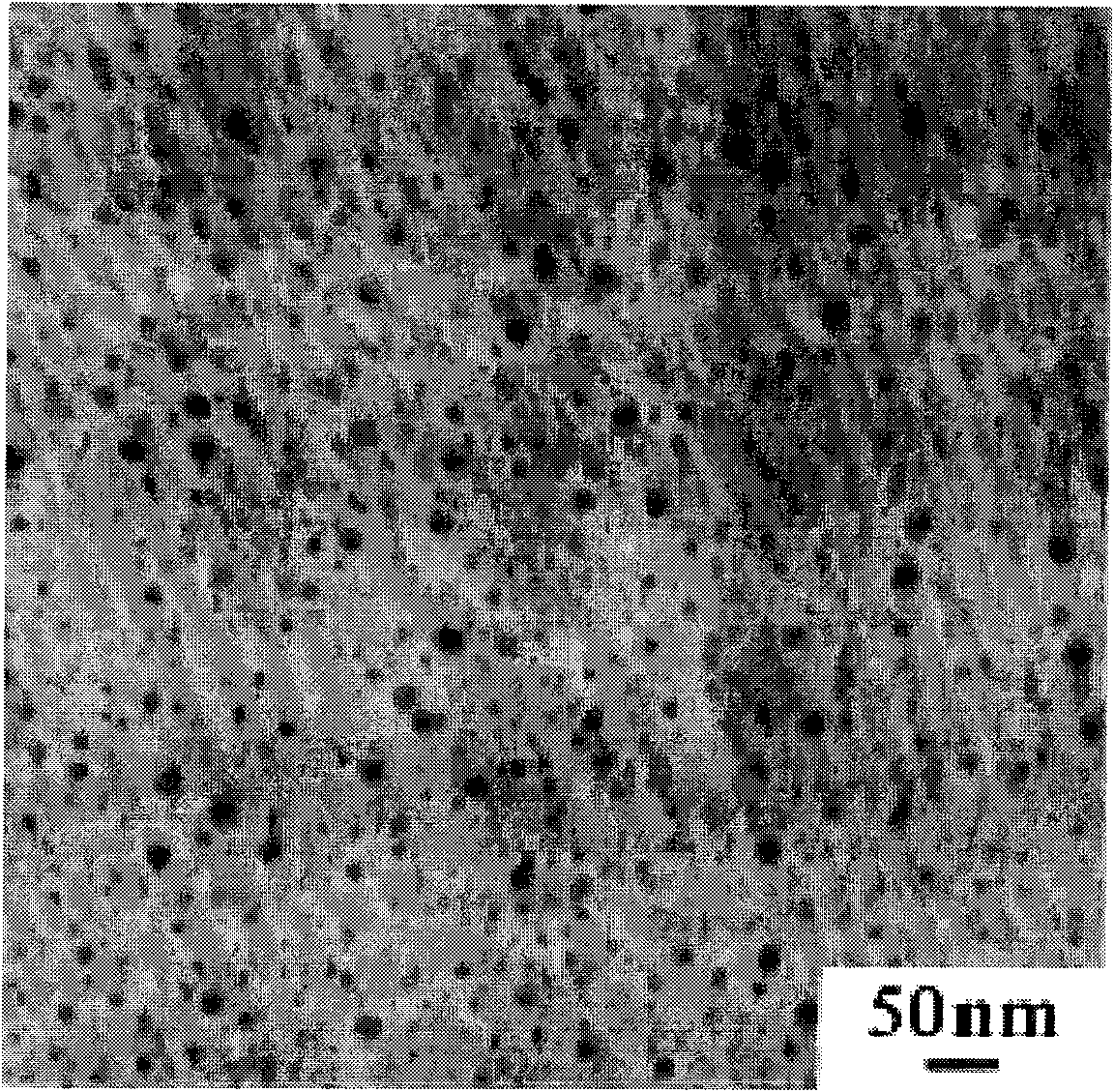

[0040] Embodiment 2, a kind of TiO with core-shell structure 2 / SiO 2 / Fe 3 o 4 A method for preparing nanoparticles, comprising the following steps:

[0041] (1) Specifically: 16mmol of FeCl 3 .6H 2 O with 8mmol of FeCl 2 .4H 2 O was added to 190ml deionized water and magnetically stirred at room temperature, and 10ml of 25% ammonia water was added to continue stirring for 10 minutes, a black precipitate was formed, which was washed with magnetic separation and water for 3 times;

[0042] (2) to Fe 3 o 4 The particle surface is treated to make it stable in aqueous solution.

[0043] The specific treatment is as follows:

[0044] a. Use 2M HNO 3 Wash twice, filter, add NaOH to raise the pH to 2, keep the pH at 2, add 5ml of 0.5M Na to the solution 3 [C 3 h 5 (COO) 3 ] The solution was stirred for 1.5 hours;

[0045] b. Wash with deionized water, dilute the solution to 50ml, the pH value is about 6, and the concentration is 30nmol ml -1 ; Stable dispersed super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com