Coupled hydrogen-rich fuel reformation hydrogen making system

A reforming hydrogen production, coupled technology, applied in hydrogen, sustainable manufacturing/processing, inorganic chemistry, etc. The internal structure of the whole device has no problems such as energy utilization, so as to achieve the effect of ensuring power generation performance, reasonable structure and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

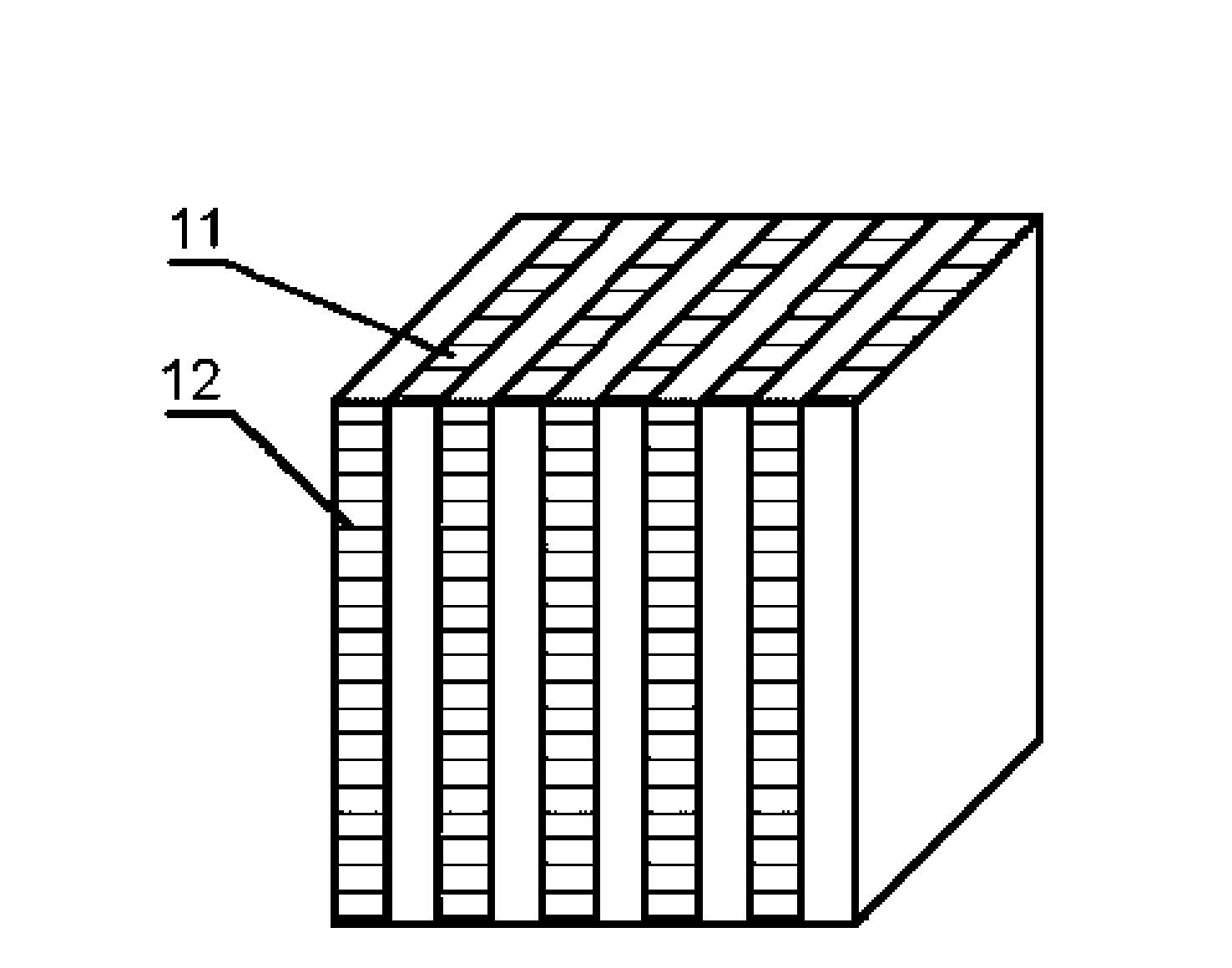

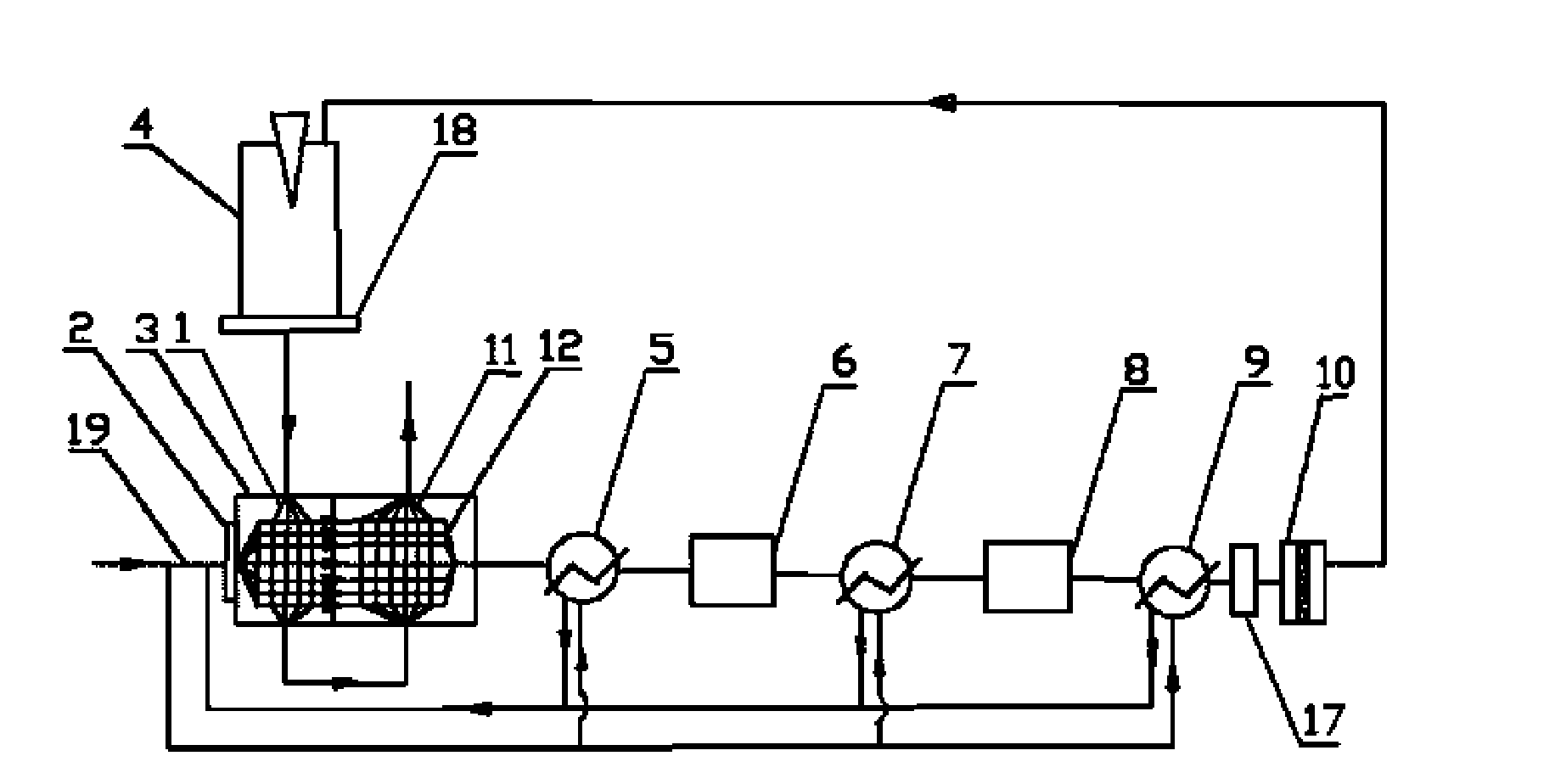

[0040] A coupled hydrogen-rich fuel reforming hydrogen production system, such as figure 1 ,2 As shown, it includes a heat supply unit 4 and a CO purification and removal unit. The system also includes a coupled reforming reactor 3. The coupled reforming reactor 3 has a plate-fin structure inside, including a heat exchange zone 1, a heat exchange In the reaction zone 11, the raw material fin pipeline 12 runs through the heat exchange zone 1 and the heat exchange reaction zone 11, and the raw material fin pipeline in the heat exchange reaction zone 11 is equipped with a reforming reaction catalyst; the outlet of the raw material fin pipeline 12 It communicates with the inlet of the CO purification and removal unit, and the outlet of the CO purification and removal unit communicates with the hydrogen inlet of the fuel cell 10 through the heat exchanger 9; The inlet of heat zone 1 is connected, and the outlet of heat exchange zone 1 is connected with the inlet of heat exchange re...

Embodiment 2

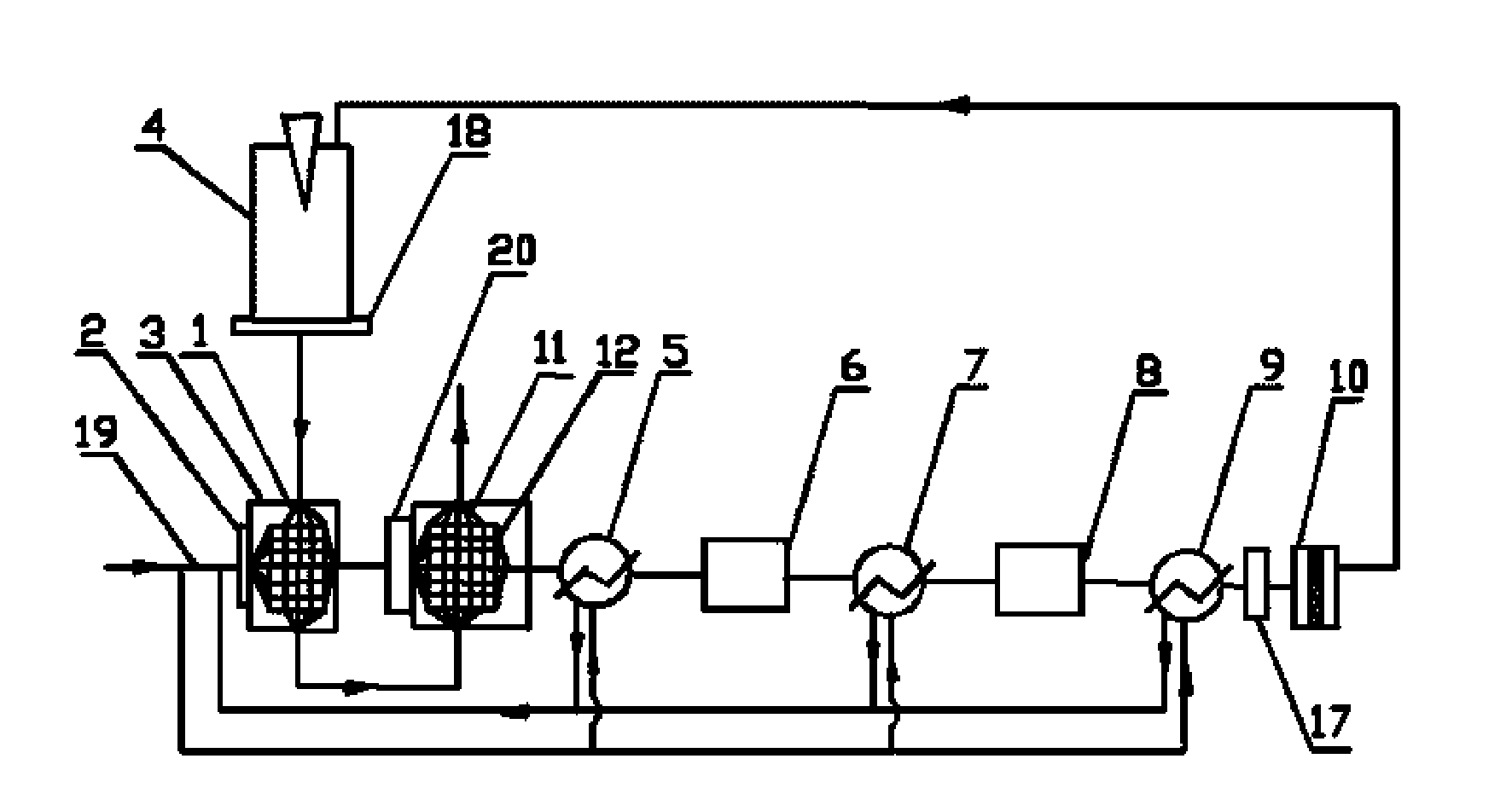

[0054] Reaction system and operation are substantially identical with embodiment 1, as image 3 As shown, the difference is that the raw material finned pipelines in the heat exchange zone 1 and the heat exchange reaction zone 11 are connected by pipelines, and a gas uniform distributor 20 is arranged on the pipelines; the cold material of each heat exchanger 5, 7, 9 The outlets are all connected in parallel to the pipeline, and then enter the raw material finned pipeline of the heat exchange reaction zone 11.

Embodiment 3

[0056] A coupled hydrogen-rich fuel reforming hydrogen production system, such as figure 1 , 4 As shown, it includes a heat supply unit 4 and a CO purification and removal unit. The system also includes a coupled reforming reactor 3. The coupled reforming reactor 3 has a plate-fin structure inside, including a heat exchange zone 1, a heat exchange Reaction zone 11, the heat exchange reaction zone 11 is equipped with a reforming reaction catalyst, the raw material finned pipeline 12 runs through the heat exchange zone 1 and the heat exchange reaction zone 11, the raw material between the heat exchange zone 1 and the heat exchange reaction zone 11 The finned pipelines are connected by pipelines, and a gas uniform distributor 20 is arranged on the pipelines; a CO shift reaction unit is arranged between the coupled reforming reactor 3 and the CO purification removal unit, including high and low temperature shift reactors 14, 16. Heat exchangers 13 and 15 respectively located at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com