Method for producing modified conjugated diene polymer, modified conjugated diene polymer, and rubber composition

一种橡胶组合物、共轭二烯的技术,应用在轮胎零部件、车辆部件、特殊轮胎等方向,能够解决改性改良少、橡胶组合物改性效果未必充分、无法获得橡胶改性效果等问题,达到加工性良好、耐磨耗性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

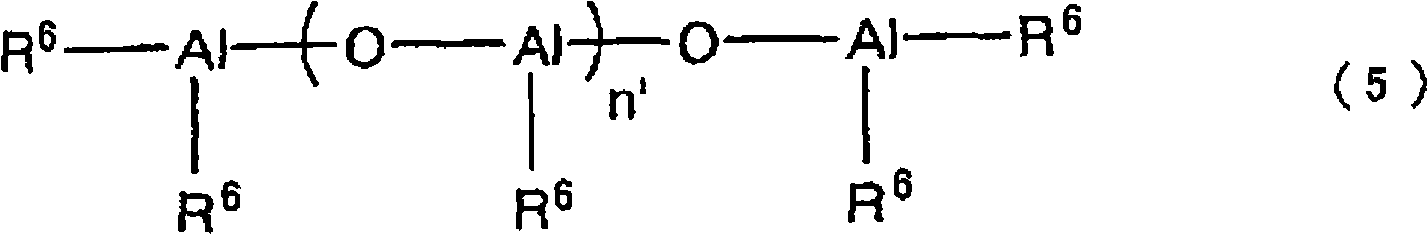

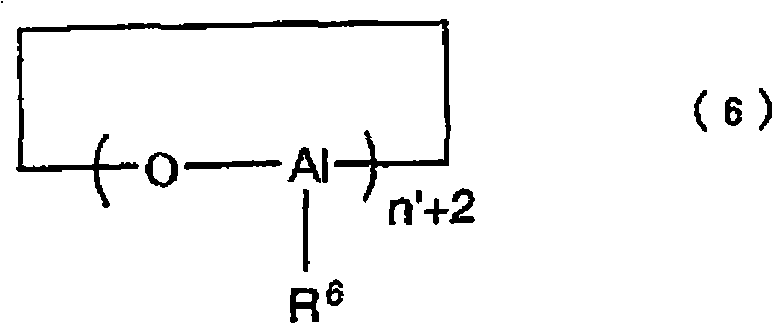

Method used

Image

Examples

Embodiment 1

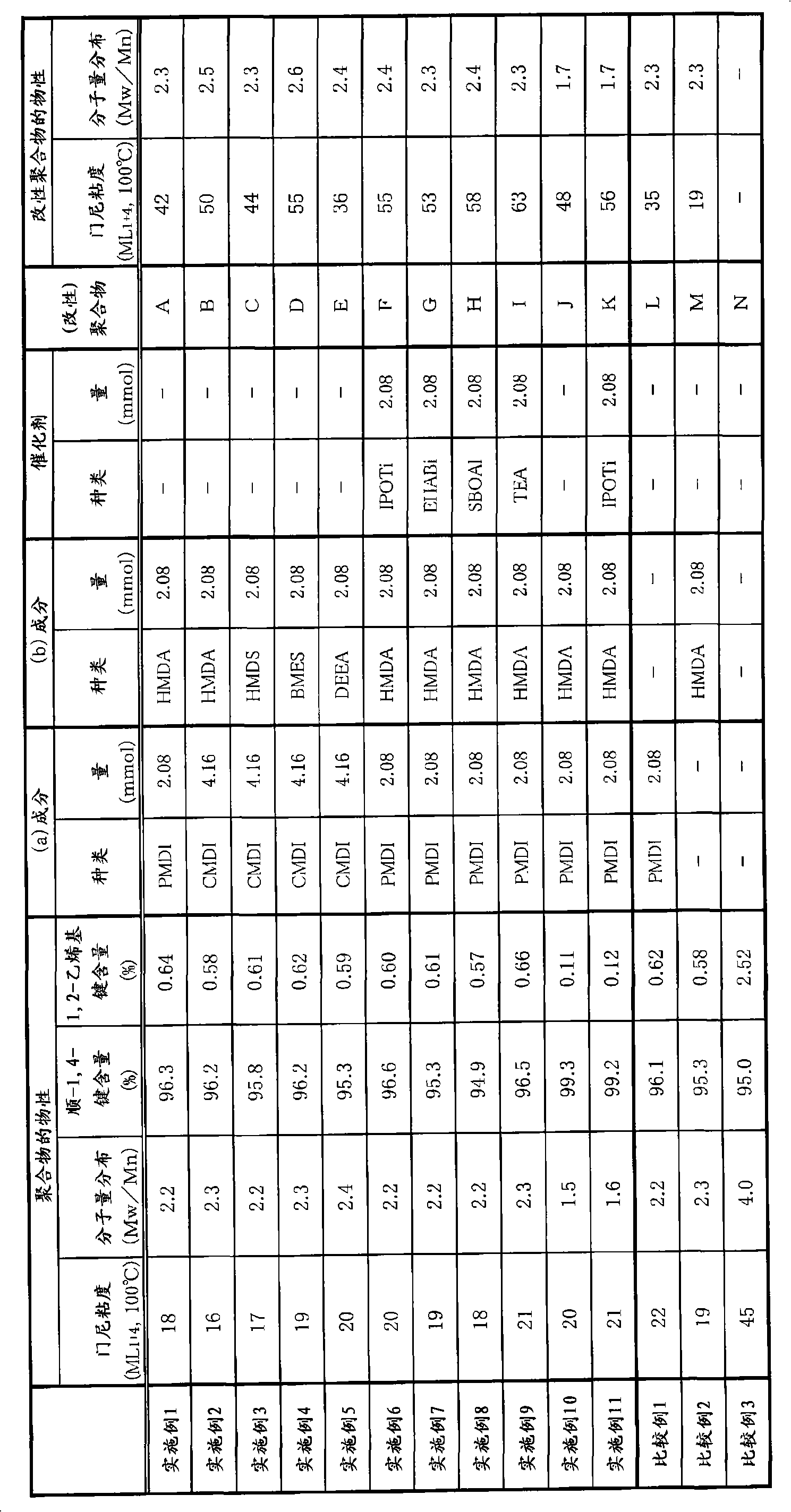

[0176] Embodiment 1 (manufacture of modified polymer A):

[0177] In a nitrogen-substituted 5-liter reactor, 2.4 kg of cyclohexane and 300 g of 1,3-butadiene were charged under a nitrogen atmosphere. To this, a cyclohexane solution of neodymium tertiary carbonate (0.09 mmol), a toluene solution of methylaluminoxane (hereinafter also referred to as "MAO") (3.6 mmol), hydrogenated diisobutyl A toluene solution of aluminum (hereinafter also referred to as "DIBAH") (5.5mmol) and diethylaluminum chloride (0.18mmol) was reacted with 1,3-butadiene (4.5mmol) at 40°C and aged for 30 minutes. The obtained catalyst was polymerized at 60°C for 60 minutes. The reaction conversion of 1,3-butadiene was almost 100%.

[0178] Take out 200 g of this polymer solution into a methanol solution containing 0.2 g of 2,4-di-tert-butyl-p-cresol, stop the polymerization, remove the solvent by stripping, and dry with a roller at 110° C. to obtain Polymer before modification (conjugated diene polymer)....

Embodiment 2

[0184] Embodiment 2 (manufacture of modified polymer B):

[0185] In addition to using polymethylene polyphenyl polycyanate (trade name "PAPI*135" (manufactured by DOWCHEMICAL, Japan)) (hereinafter also referred to as "CMDI" (4.16mmol in NCO conversion)) instead of in Example 1 Modified polymer B (modified conjugated diene polymer) was obtained in the same manner as in Example 1, except for the PMDI (2.08 mmol). Table 1 shows the modification conditions and the results of the modification reaction.

Embodiment 3

[0186] Embodiment 3 (manufacture of modified polymer C):

[0187] Except using hexamethyldisilazane (hereinafter also referred to as "HMDS") instead of HMDA in Example 2, all the other operations were performed in the same manner as in Example 2 to obtain modified polymer C (modified conjugated di ethylenic polymers). Table 1 shows the modification conditions and the results of the modification reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com