Method and device for treating high ammonia nitrogen water

A kind of treatment equipment, high ammonia nitrogen technology, applied in the direction of neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high energy consumption, high operating cost, and difficulty in normal growth of organisms And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

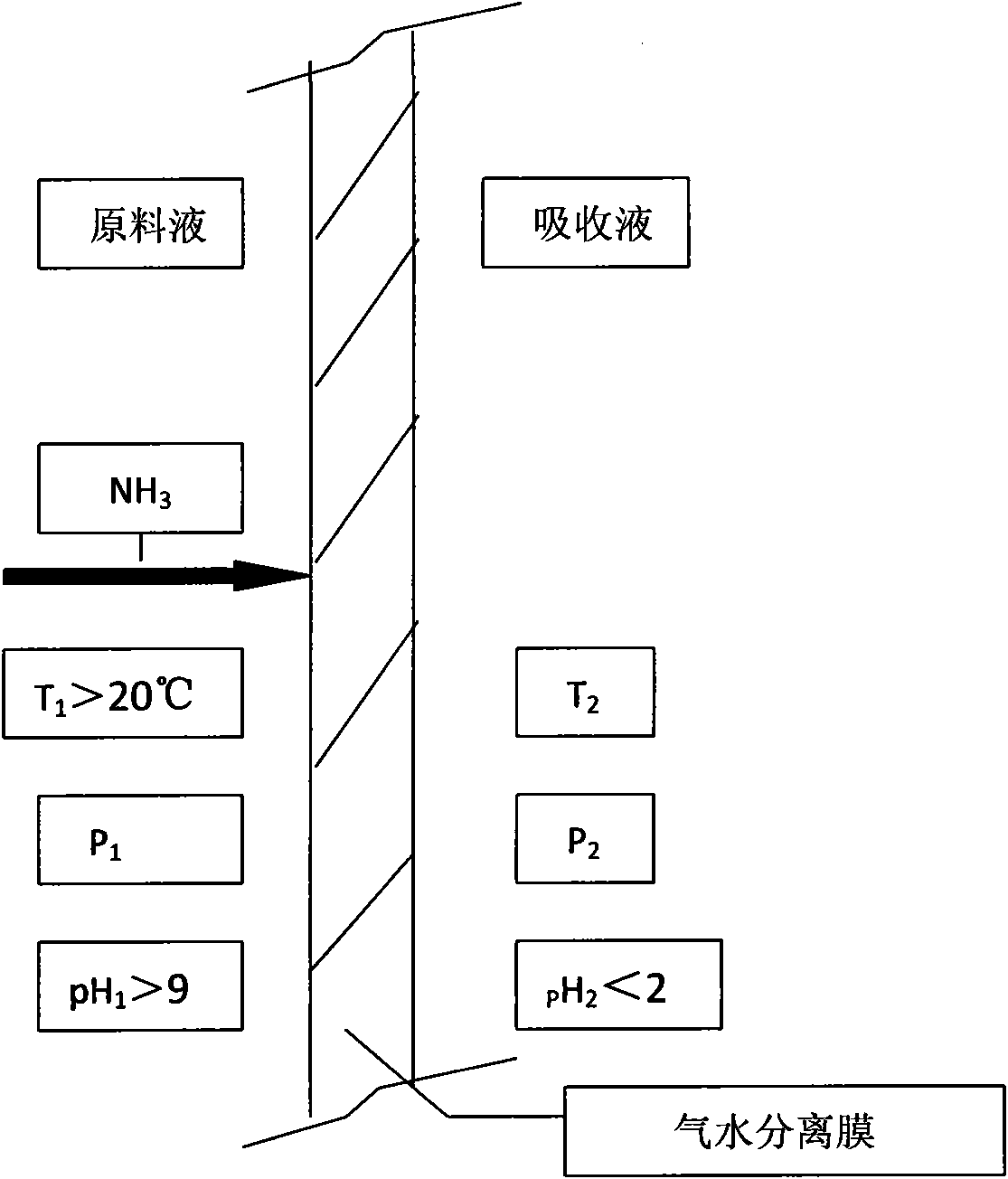

[0037] The above method, wherein T1=20°C, T2=20°C; P1=0.15MPa, P2=0.08MPa; pH1=9.5.

[0038] The temperature of the treated water is 20°C, the concentration of ammonia nitrogen is 10000mg / L-12000mg / L, and the pH of the treated wastewater is adjusted to 9.5 with lime solution. The said containing H + The absorption liquid is 5% hydrochloric acid aqueous solution, pH is less than 0. Using this device for treatment, the concentration of ammonia nitrogen in the effluent is 15mg / L. When the ammonium salt concentration in the absorbing liquid reaches 20%, it is sent to the heating evaporation equipment to obtain solid ammonium chloride.

Embodiment 2

[0039] Embodiment 2, the above method, wherein T1=30°C, T2=30°C; P1=0.2MPa, P2=0.1MPa; pH1=10.

[0040] The temperature of the treated water is 30°C, the concentration of ammonia nitrogen is 6000mg / L-8000mg / L, and the pH of the treated wastewater is adjusted to 10 by using 30% caustic soda solution. The said containing H + The absorption liquid is 7% nitric acid aqueous solution, pH is less than 0. Using this device for treatment, the concentration of ammonia nitrogen in the effluent is 10mg / L. When the ammonium salt concentration in the absorption liquid reaches 25%, it is sent into the heating evaporation equipment to obtain solid ammonium nitrate,

Embodiment 3

[0041] Embodiment 3, the above method, wherein T1=40°C, T2=40°C; P1=0.12MPa, P2=0.05MPa; pH1=10.5.

[0042] The temperature of the treated water is 40°C, the concentration of ammonia nitrogen is 1000mg / L-3000mg / L, and the pH of the treated wastewater is adjusted to 10.5 by using 50% caustic soda solution. The said containing H + The absorption liquid is 10% sulfuric acid aqueous solution, pH is less than 0. Using this device for treatment, the concentration of ammonia nitrogen in the effluent is 8mg / L. When the ammonium salt concentration in the absorbing liquid reaches 30%, it is sent to the heating and evaporating equipment to obtain solid ammonium sulfate.

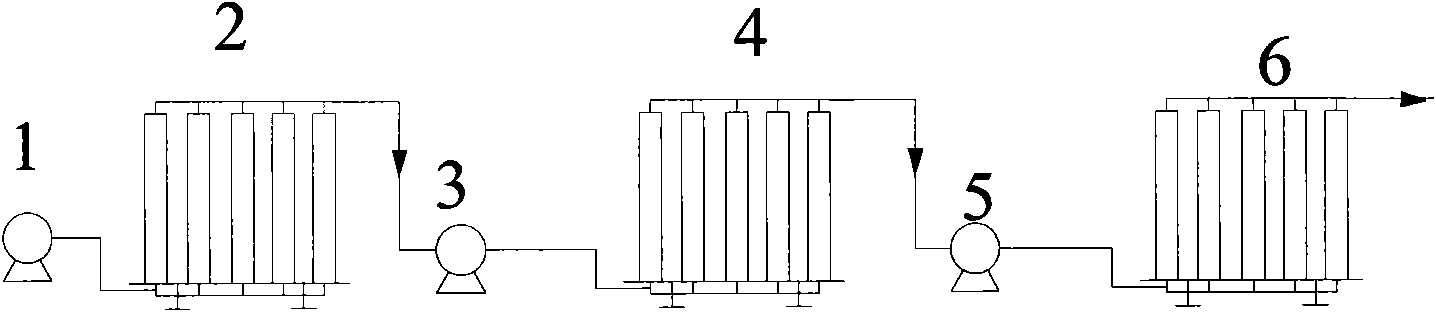

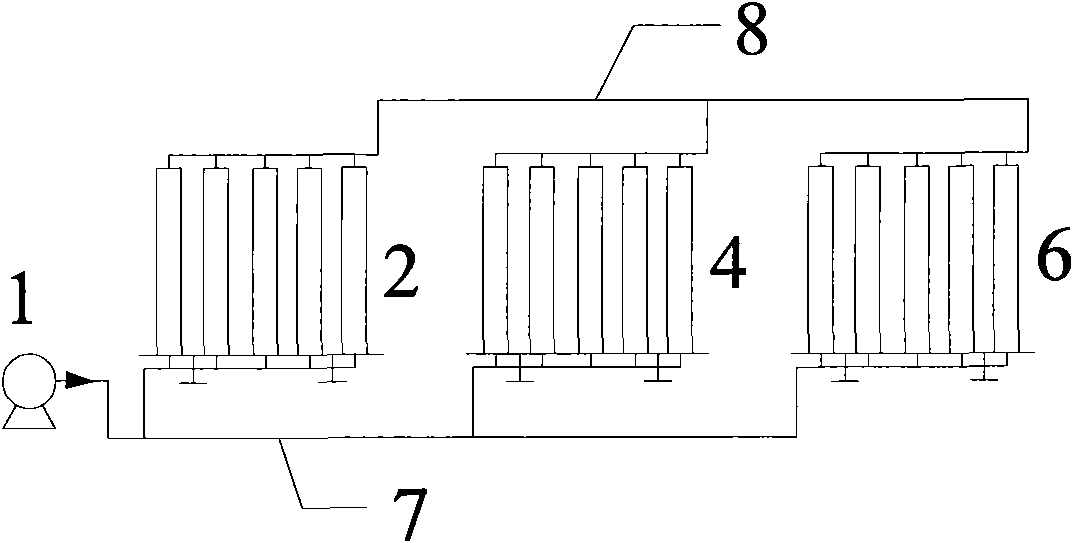

[0043] see figure 2 , figure 2 It is a schematic diagram of the series connection of multi-stage gas-water separation membrane units. The outlet of the first-stage booster pump 1 is connected to the feed-liquid inlet of the first-stage gas-water separation membrane unit 2 (a certain number of gas-water separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com