Process for efficiently leaching anode active material of waste lithium battery

A technology for positive active materials and waste lithium batteries, which is applied in the field of high-efficiency leaching of positive active materials for waste lithium batteries, and can solve problems such as high cost, large environmental pollution, and low leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

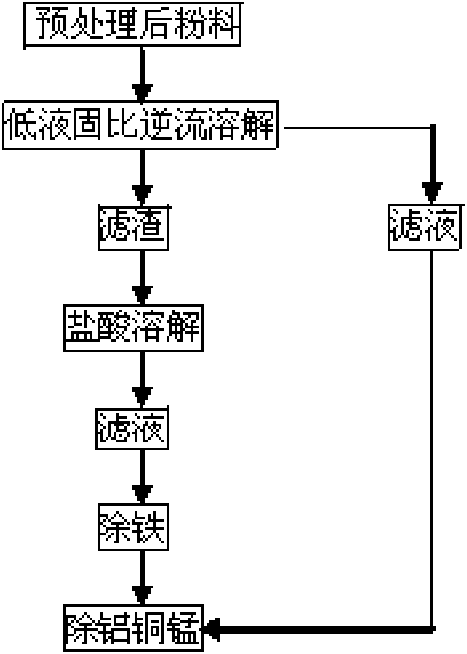

Image

Examples

Embodiment 1

[0018] Weigh and disassemble the waste lithium-ion battery to obtain 300g of powder material, which is ground to pass through an 80-mesh sieve (average particle size is less than 178 microns). Add 300ml of hydrogen peroxide (30wt%) and 600ml of a mixed solution with a sulfuric acid concentration of 2mol / L, and stir and leach in two stages at 80°C for 3 hours. After filtering, the filtrate is sent to the next purification and impurity removal process, and the remaining residue is stirred at 80°C for 1 hour with 2 mol / L hydrochloric acid at a solid-to-liquid ratio of 1:1 g / ml. Filter, and the filtrate is sent to the next stage of purification process. The leaching rate of the active material in this embodiment is about 96.5%.

Embodiment 2

[0020] Weigh and disassemble the waste lithium-ion battery to obtain 300 g of powder material, which is ground to pass through an 80-mesh sieve. Add 300ml of hydrogen peroxide (30wt%) and 600ml of a mixed solution with a sulfuric acid concentration of 4mol / L, and stir and leach in two stages at 90°C for 3 hours. Filter, and send the filtrate to the next stage of purification process, and use 2mol / L hydrochloric acid to make the solid-to-liquid ratio 1:1g / ml for the remaining residue, and stir at 80°C for 2 hours. Filter, and the filtrate is sent to the next stage of purification process. The leaching rate of the active material in this embodiment is about 98%.

Embodiment 3

[0022] Weigh and disassemble the waste lithium-ion battery to obtain 300 g of powder material, which is ground to pass through an 80-mesh sieve. Add 450ml of hydrogen peroxide (30wt%) and 600ml of a mixed solution with a sulfuric acid concentration of 4mol / L, and stir and leach in 5 stages at 90°C for 4 hours. Filter, and send the filtrate to the next stage of purification process, and use 3mol / L hydrochloric acid to make the solid-to-liquid ratio 1:1g / ml for the remaining residue, and stir at 90°C for 2 hours. Filter, and the filtrate is sent to the next stage of purification process. The leaching rate of the active material in this embodiment reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com