Method and device for preparing calcitriol by utilizing photochemical reaction

A technology of photochemical reaction and calcitriol, which is applied in chemical industry, organic chemistry, chemical/physical/physicochemical process of energy application, etc., can solve undiscovered problems and achieve convenient operation, energy saving and strong environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

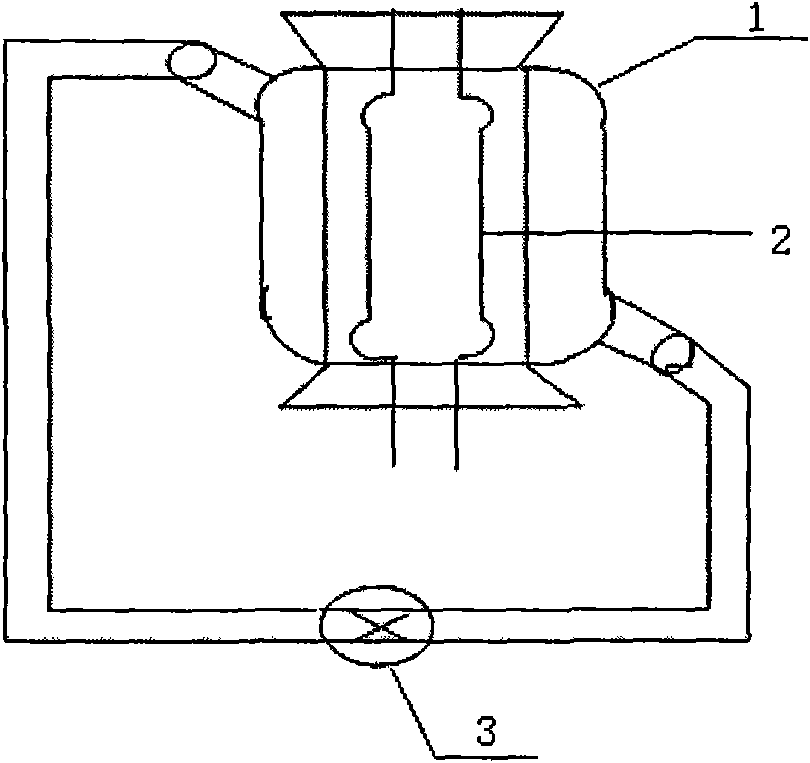

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is carried out in a reaction device, 1 g of a 5,6-trans isomer sample with a purity greater than 95% is dissolved in 1000 ml of absolute ethanol; the selected light reaction temperature is 25 ± 5 ° C, and the circulation flow rate is 50 ml / min, after the photochemical reaction is completed, the reaction solution is concentrated to dryness with a rotary evaporator to obtain a light yellow solid, which is recrystallized with ethyl acetate-n-pentane at a volume ratio of 1:3 to obtain white needle crystals 0.732g; detected by HPLC, the content is 99.6%, by IR, UV-VIS, 1 HNMR, 13 CNMR and other spectra confirmed that the product obtained by the photochemical reaction was calcitriol, and the conversion rate of the light reaction was 76.9%.

Embodiment 2

[0023] This example is carried out in a reaction device, 1 g of a sample with a 5,6-trans isomer purity greater than or equal to 95% is dissolved in 5000 ml of absolute ethanol; the light reaction temperature is adjusted to 25 ± 5 ° C, and the circulation flow rate is 50 ml / min, after the photochemical reaction is completed, the reaction solution is concentrated to dryness with a rotary evaporator under reduced pressure to obtain a light yellow solid and ethyl acetate-n-pentane at a volume ratio of 1:3 for recrystallization to obtain 0.758 g of white needle crystals ; Detected by HPLC, the content is 99.8%, by IR, UV-VIS, 1 HNMR, 13 CNMR and other spectra confirmed that the product obtained by the photochemical reaction was calcitriol, and its photoreaction conversion rate was 78.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com