Cleaning and dust collecting method of volatilized zinc oxide and device thereof

A technology of zinc oxide and sub-zinc oxide, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of serious dust pollution, high labor intensity of workers, and no solution to bag dust collection technology. To achieve the effect of shortening the process flow, reducing the cooling area and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

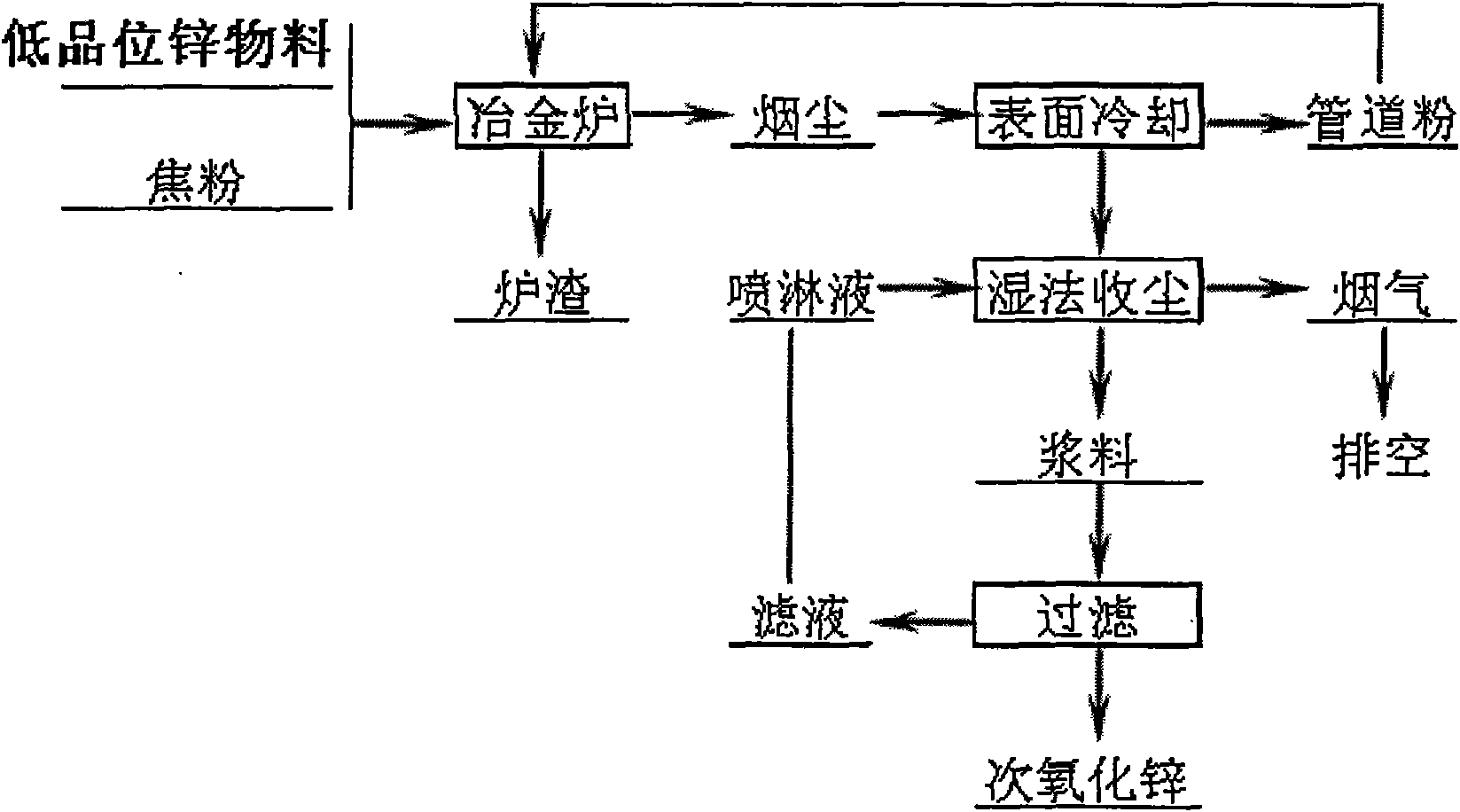

Problems solved by technology

Method used

Image

Examples

Embodiment 1

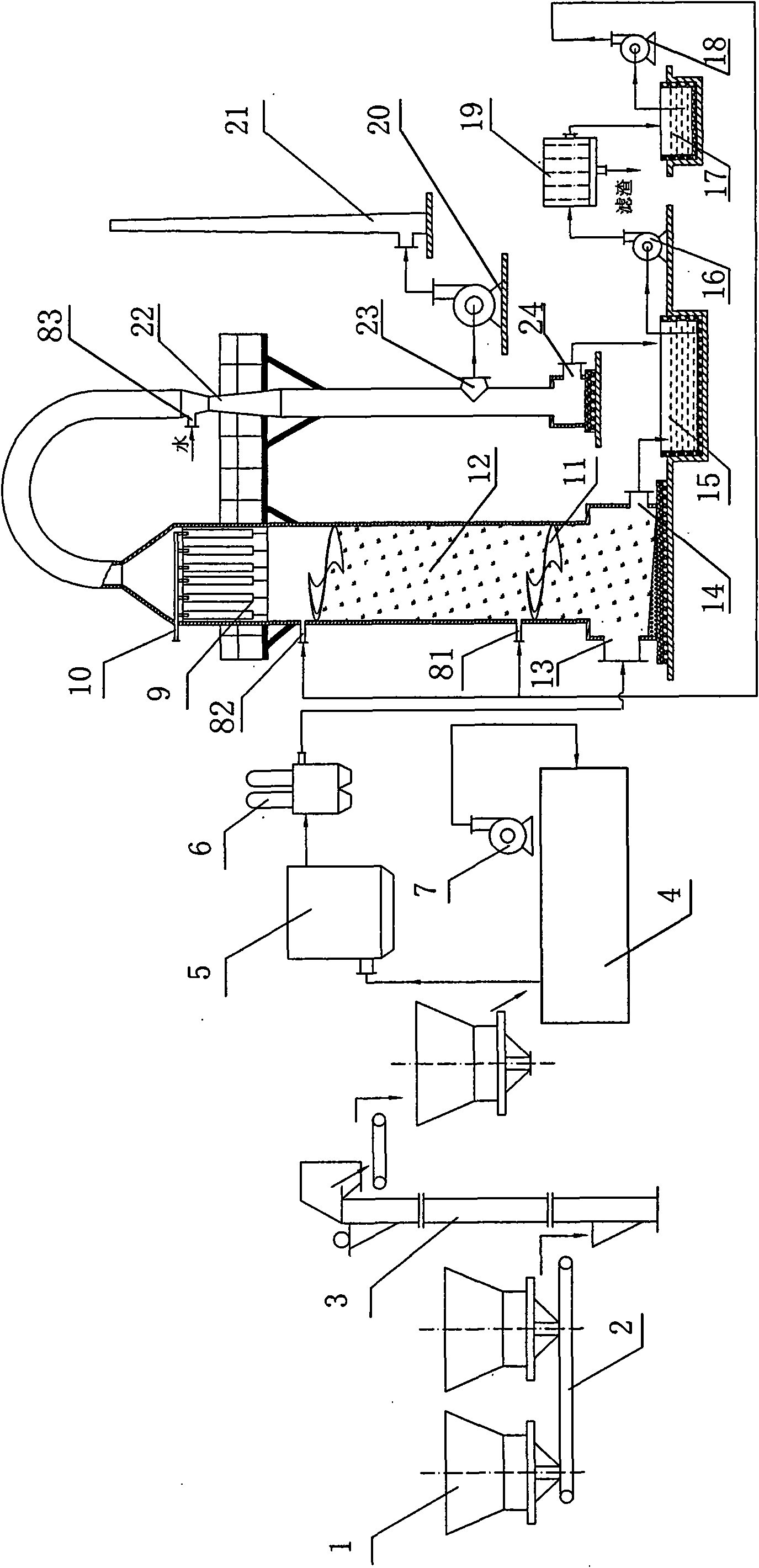

[0031] control figure 2 , the cleaning and dust collection device of volatile zinc oxide according to the present invention mainly consists of a disc feeder 1, a belt conveyor 2, a bucket elevator 3, a metallurgical furnace 4, a waste heat boiler 5, a surface cooler 6, and an air compressor 7. Spray water inlet 81, 82, 83, cloth bag chamber 9, high-pressure air inlet 10, spiral sprayer 11, spray-bag tower 12, surface cooling flue gas inlet 13, slurry outlet 14, slurry pool 15. Slurry pump 16, filtrate tank 17, water pump 18, filter press 19, induced draft fan 20, chimney 21, Venturi dust collector 22, flue gas outlet 23, slurry outlet 24 and other components.

[0032] Taking the metallurgical furnace 4 as a rotary kiln as an example, the connection mode and working process of the cleaning and dust collection device for volatilizing zinc oxide are as follows:

[0033] According to the coking coal rate of 50wt%, that is, zinc leaching slag: coke powder is 1:0.5wt, the zinc lea...

Embodiment 2

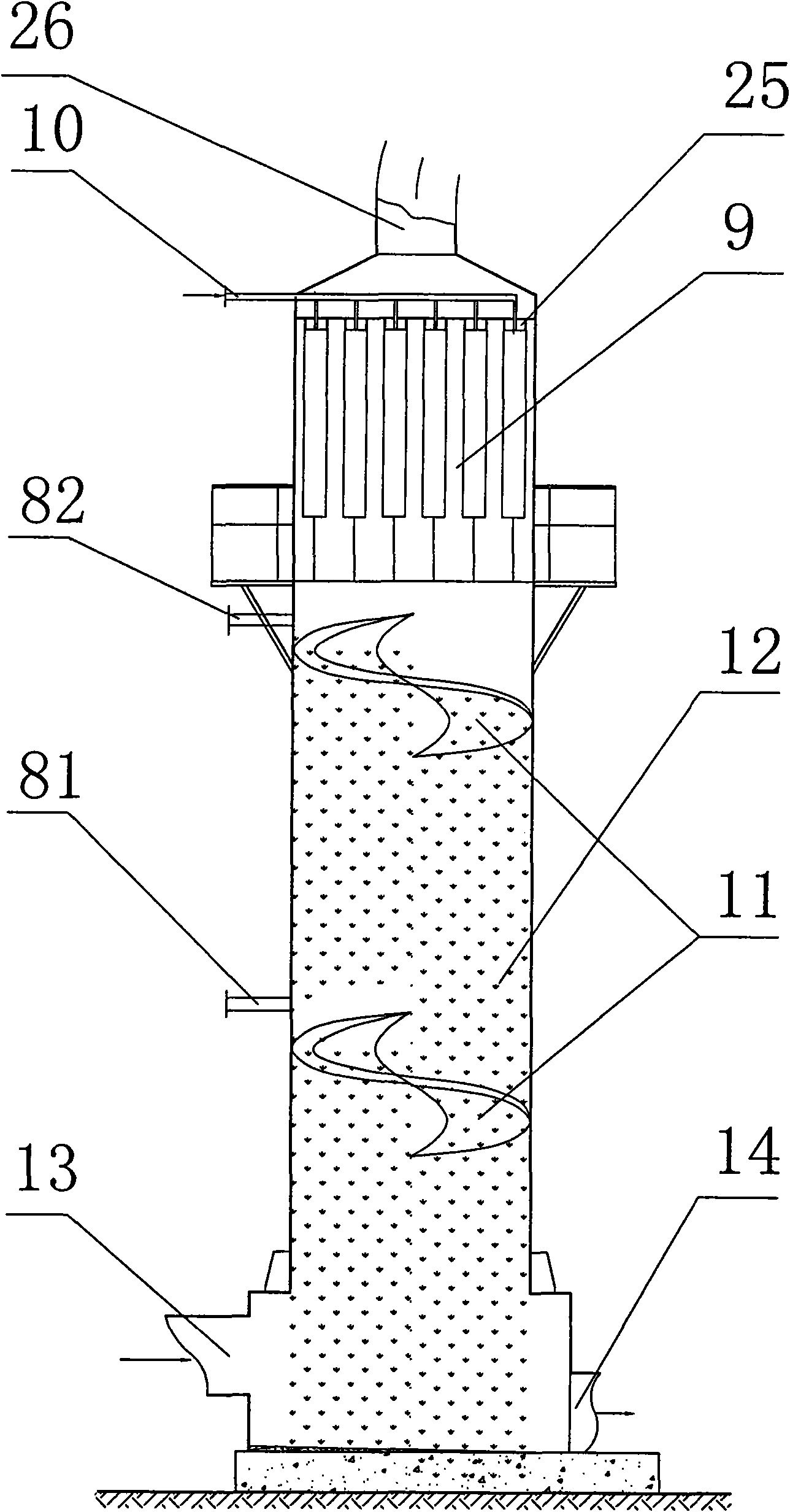

[0036] This embodiment is a detailed description of the structure and application of the spray-bag tower.

[0037] control image 3 , the spray-bag tower of the cleaning and dust collecting device of volatilized zinc oxide of the present invention, the spray-bag tower is the core device of the present invention, mainly consists of spray water inlet 81,82, bag chamber 9, high-pressure gas inlet 10 , spiral sprayer 11, spray-bag tower 12, flue gas inlet 13 from surface cooling, slurry outlet 14, bag holder 25 and furnace top outlet pipe 26.

[0038] The connection mode and working process of the spray-bag tower of the cleaning and dust collecting device of described volatile zinc oxide are as follows:

[0039]The spray-bag tower is a columnar body, which is divided into three sections. From the bottom of the tower, the first and second sections use two spiral showers 11 to realize uniform spraying, and the third section is the baghouse 9. Cloth bag holder 25 is fixed. The flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com