Catalyst for producing methyl cyclohexanecarboxylate and application thereof

A technology of methyl cyclohexyl carboxylate and methyl benzoate, which is applied in the field of catalysts and their preparation, can solve the problems of complex separation of products and catalysts, easily broken activated carbon, and many post-treatment procedures, so as to improve the ability to resist CO poisoning , improve the conversion rate and simplify the separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

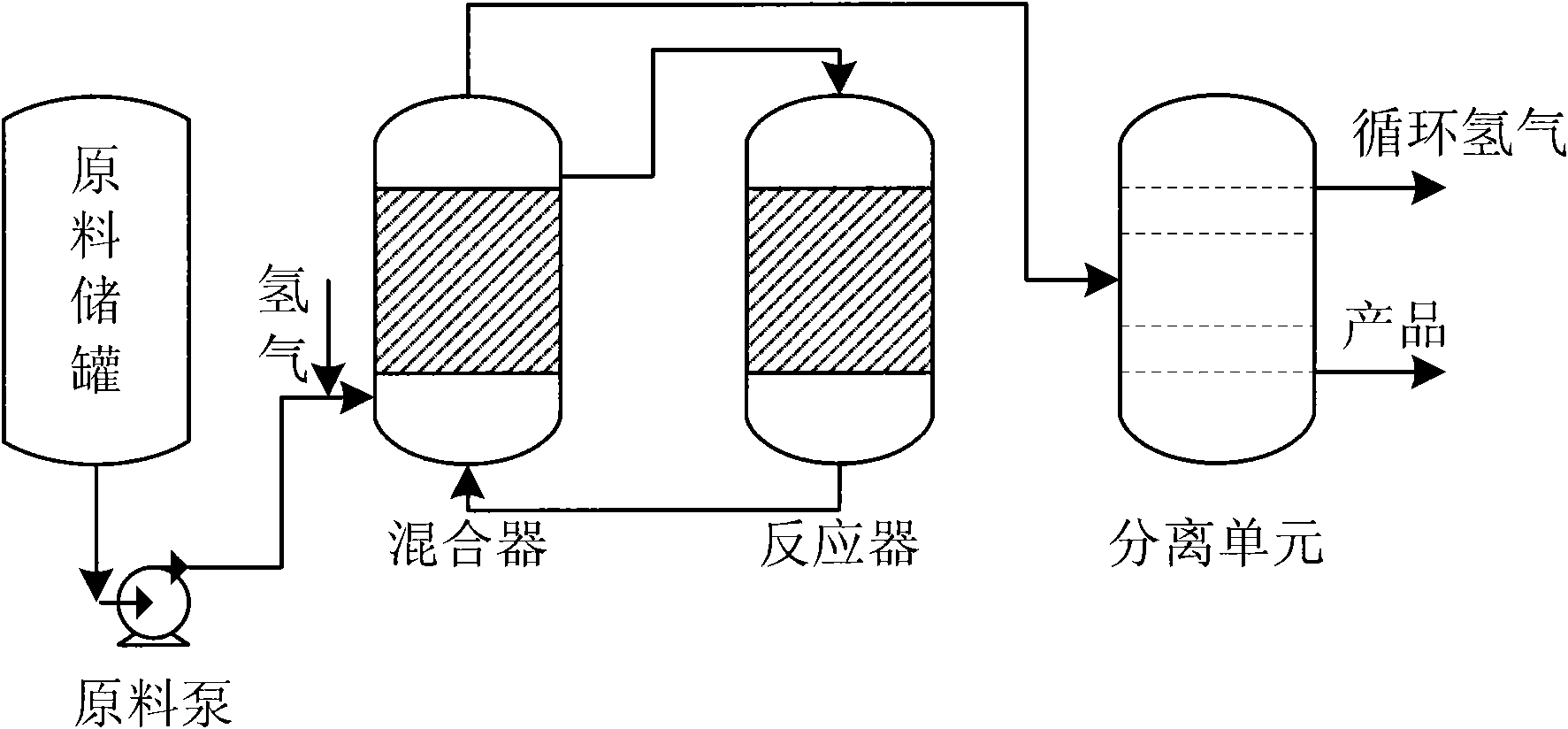

Image

Examples

Embodiment 1

[0020] Weigh 0.7 g of Mg(NO 3 ) 2 4H 2 O, dissolved in 24 milliliters of water, impregnated with this aqueous solution weighed 25 grams of aluminum oxide (average particle size is 40 mesh, specific surface area 180m 2 / g). Dry at 110°C and decompose by roasting at 500°C for 5 hours. Take 4 mL of PdCl 2 Mix hydrochloric acid aqueous solution (0.127g Pd / ml) and 20 milliliters of water, impregnate the above-mentioned roasted catalyst intermediate, dry naturally, dry at 120°C, roast at 450°C, and reduce in hydrogen flow at 280°C for 2 hours.

Embodiment 2

[0022] Weigh 0.7 g of Ca(NO 3 ) 2 4H 2 O, dissolved in 24 ml of water, impregnated with this aqueous solution weighed 35 grams of aluminum oxide (average particle size is 40 mesh, specific surface area 180m 2 / g). Dry at 110°C and decompose by roasting at 500°C for 5 hours. Take 4 mL of PdCl 2 Mix hydrochloric acid aqueous solution (0.127g Pd / ml) and 20 milliliters of water, impregnate the above-mentioned roasted catalyst intermediate, dry naturally, dry at 120°C, roast at 450°C, and reduce in hydrogen flow at 280°C for 2 hours.

Embodiment 3

[0024] Weigh 0.7 g of Ca(NO 3 ) 2 4H 2 O, dissolved in 24 milliliters of water, impregnated with this aqueous solution weighed 25 grams of aluminum oxide (average particle size is 40 mesh, specific surface area 180m 2 / g). Dry at 110°C and decompose by roasting at 500°C for 5 hours. Take 1 mL of PdCl 2 Aqueous solution (0.127g Pd / ml) plus 2ml RuCl 2 Aqueous solution (0.013g Ru / ml) was added to 18ml of water to make a mixed solution. Then, impregnate the above calcined catalyst intermediate with this mixed solution, dry, calcinate at 450°C, and reduce in hydrogen flow at 280°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com