Preparation method of S-3-aminoquinuclidine dihydrochloride

A technology of aminoquinine dihydrochloride and S-3-, applied in the field of preparation of S-3-aminoquinine dihydrochloride, can solve the problem of affecting yield and cost, affecting yield and cost, and inconvenient operation and other problems, to achieve the effect of low cost, high yield and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

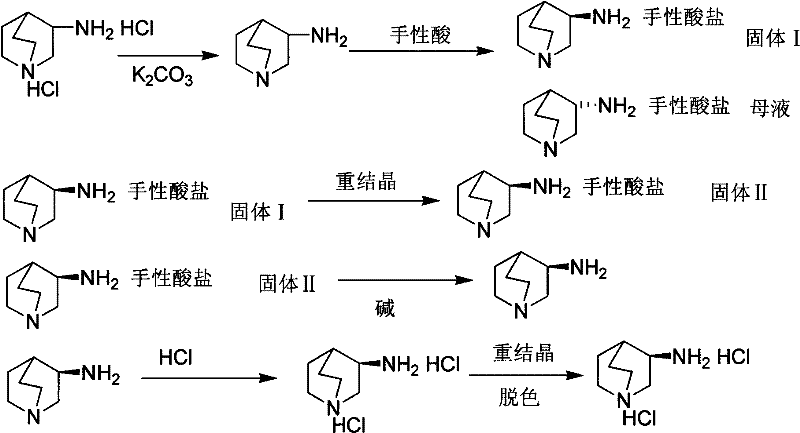

[0029] The preparation method of S-3-aminoquinine dihydrochloride is realized through the following steps:

[0030] 1) Preparation of S-3-aminoquinine-D-tartrate

[0031] Add 10g of 3-aminoquinine dihydrochloride and 150ml of methanol to a 250ml single-necked bottle, cool in an ice-water bath to 0-5°C, add 6.9g of potassium carbonate, stir at room temperature for 1 hour after the addition, and filter to remove the inorganic salt potassium chloride. Under stirring at 50°C, 7.3 g of D-tartaric acid was added to the mother liquor, stirred for 1 hour to form a salt, a large amount of solids precipitated, the solids were filtered, washed with a small amount of solvent, and dried to obtain 7.2 g.

[0032] Mp: 213-215°C, [α] D 20 =-35.0 0 (C=1, H 2 O).

[0033] 2) recrystallization of S-3-aminoquinine-D-tartrate,

[0034] Measure 50ml of methanol into a 250ml single-mouth bottle, add the salt obtained in step 1), raise the temperature to 50°C, stop heating after the salt is com...

Embodiment 2

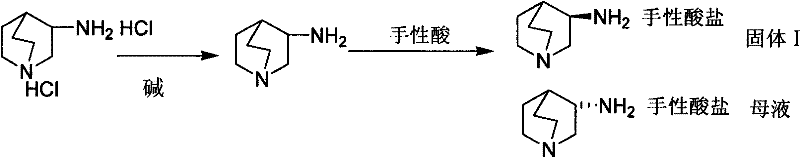

[0044] The preparation method of S-3-aminoquinine dihydrochloride is realized through the following steps:

[0045] 1) Preparation of S-3-aminoquinine-D-camphorsulfonate

[0046] Add 10g of 3-aminoquinine dihydrochloride and 150ml of absolute ethanol to a 250ml single-necked bottle, cool in an ice-water bath to 0-5°C, slowly add 8.5g of sodium bicarbonate, the whole addition process lasts for 1 hour, and stir at room temperature after the addition is complete 1.5h, filter to remove the inorganic salt sodium chloride, add 12.8g of D-camphorsulfonic acid to the mother liquor under stirring at 30°C, stir to form a salt for 2h, a solid precipitates, filter the solid, wash the solid with a small amount of solvent, and dry to obtain 9.9 g

[0047] Mp: >300°C, [α] D 20=-49.5 0 (C=1, H 2 O).

[0048] 2) recrystallization of S-3-aminoquinine-D-camphorsulfonate,

[0049] Measure 60ml of absolute ethanol and place it in a 250ml single-mouth bottle, add the salt obtained in step 1)...

Embodiment 3

[0059] The preparation method of S-3-aminoquinine dihydrochloride is realized through the following steps:

[0060] 1) Preparation of S-3-aminoquinine-L-dibenzoyl tartrate

[0061] Add 10g of 3-aminoquinine dihydrochloride and 150ml of isopropanol to a 250ml single-necked bottle, cool in an ice-water bath to 0-5°C, slowly add 8.3g of sodium acetate, the whole adding process lasts for 1h, and stir at room temperature for 2h after the addition , filter to remove the inorganic salt sodium chloride, add 18.9 g of L-dibenzoyl tartaric acid to the mother liquor under stirring at 20°C, stir to form a salt for 3 hours, a large amount of solids precipitate, filter the solids, wash the solids with a small amount of solvent, and dry to obtain 14.0g

[0062] Mp: 179-181°C, [α] D 25 =+135 0 (C=1, H 2 O).

[0063] 2) Recrystallization of S-3-aminoquinine-D-dibenzoyl tartrate,

[0064] Measure 70ml of isopropanol into a 250ml single-mouth bottle, add the salt obtained in step 1), rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com