A preparation method of reinforced polybutylene terephthalate flame-retardant heat-conducting material

A polybutylene terephthalate and thermally conductive material technology is applied in the field of preparation of flame-retardant thermally conductive materials, which can solve the problems of low impact strength, reduced mechanical properties, and limited application range, and achieve excellent flame-retardant performance. , The effect of improving impact toughness and elastic modulus, excellent insulation and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

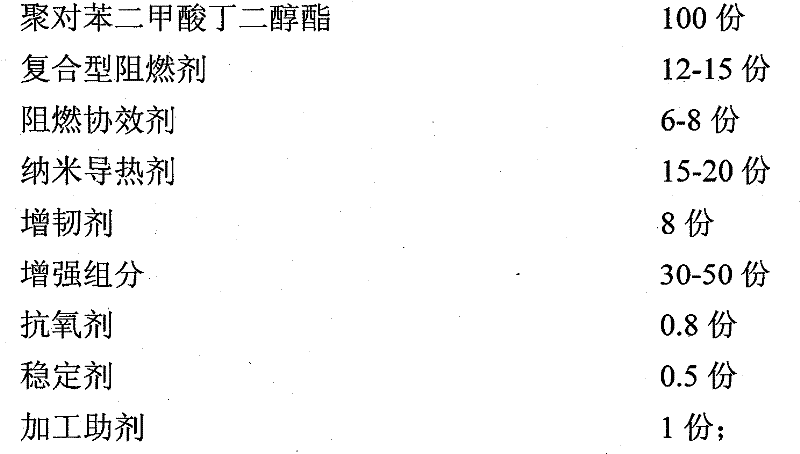

[0045] First, prepare the material: it consists of the following raw materials in parts by weight, 100 parts of polybutylene terephthalate, 12 parts of brominated polystyrene, 6 parts of antimony trioxide, 15 parts of nano-aluminum nitride, ethylene acrylic acid 8 parts of butyl ester-glycidyl methacrylate copolymer, 30 parts of glass fiber, 0.8 part of tris(2,4-di-tert-butylphenyl ester) phosphite, 0.5 part of triphenyl phosphate, 1 part of processing aid share.

[0046] Mix PBT resin and processing aid KH-550 in a high mixer for 1 minute, then mix brominated polystyrene, antimony trioxide, nano-aluminum nitride, ethylene butyl acrylate-glycidyl methacrylate copolymer, Tris(2,4-di-tert-butylphenyl ester) phosphite and triphenyl phosphate were added to the high mixer and mixed for 3 minutes, and then added to the extruder from the main feeding port; the glass treated with the interface modifier The fiber is fed into the twin-screw extruder through the glass fiber inlet for ex...

Embodiment 2

[0049] First, prepare the material: it consists of the following raw materials in parts by weight, 100 parts of polybutylene terephthalate, 14 parts of brominated polystyrene, 7 parts of antimony trioxide, 17 parts of nano-aluminum nitride, ethylene acrylic acid 8 parts of butyl ester-glycidyl methacrylate copolymer, 40 parts of glass fiber, 0.8 part of tris(2,4-di-tert-butylphenyl ester) phosphite, 0.5 part of triphenyl phosphate, 1 part of processing aid share.

[0050]Mix PBT resin and processing aid KH-550 in a high mixer for 1 minute, then mix brominated polystyrene, antimony trioxide, nano-aluminum nitride, ethylene butyl acrylate-glycidyl methacrylate copolymer, Tris(2,4-di-tert-butylphenyl ester) phosphite and triphenyl phosphate were added to the high mixer and mixed for 3 minutes, and then added to the extruder from the main feeding port; the glass treated with the interface modifier The fiber is fed into the twin-screw extruder through the glass fiber inlet for ext...

Embodiment 3

[0053] First, prepare the material: it consists of the following raw materials in parts by weight, 100 parts of polybutylene terephthalate, 15 parts of brominated polystyrene, 8 parts of antimony trioxide, 20 parts of nano-aluminum nitride, ethylene acrylic acid 8 parts of butyl ester-glycidyl methacrylate copolymer, 50 parts of glass fiber, 0.8 part of tris(2,4-di-tert-butylphenyl ester) phosphite, 0.5 part of triphenyl phosphate, 1 part of processing aid share.

[0054] Mix PBT resin and processing aid KH-550 in a high mixer for 1 minute, then mix brominated polystyrene, antimony trioxide, nano-aluminum nitride, ethylene butyl acrylate-glycidyl methacrylate copolymer, Tris(2,4-di-tert-butylphenyl ester) phosphite and triphenyl phosphate were added to the high mixer and mixed for 3 minutes, and then added to the extruder from the main feeding port; the glass fiber treated with the interface modifier It is fed into the twin-screw extruder from the glass fiber inlet for extrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com