Copperized aluminum pipe inner conductor for coaxial cable

A coaxial cable and inner conductor technology, applied in the field of cables, can solve the problems of easy occurrence of virtual welding, unstable conductivity of copper layer, easy damage, etc., and achieve the effects of simple and reasonable manufacturing process, shortening production cycle and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

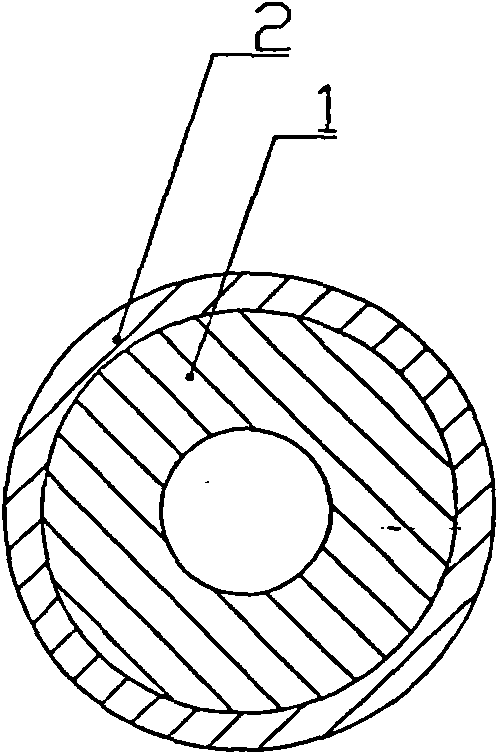

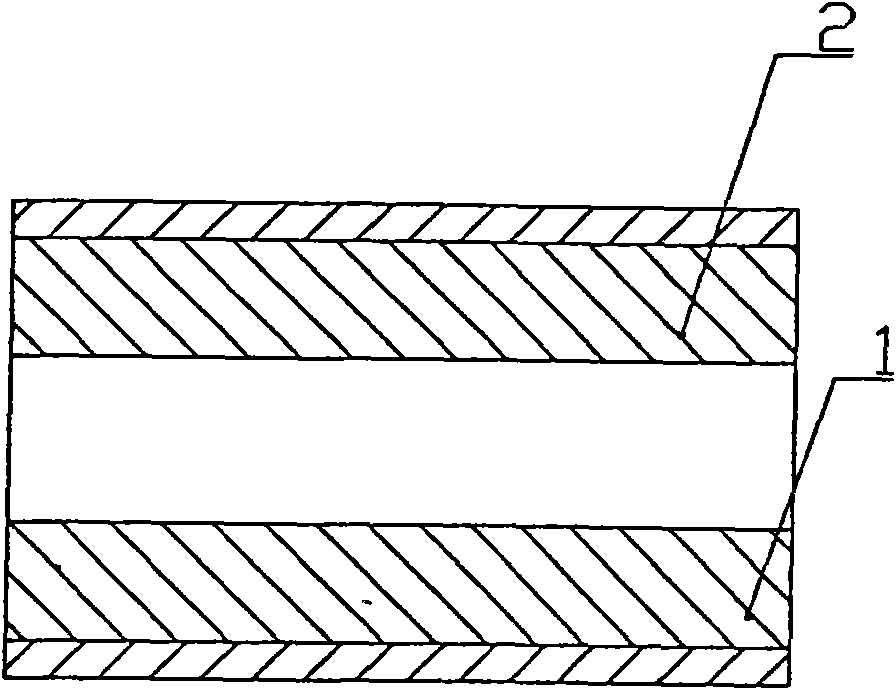

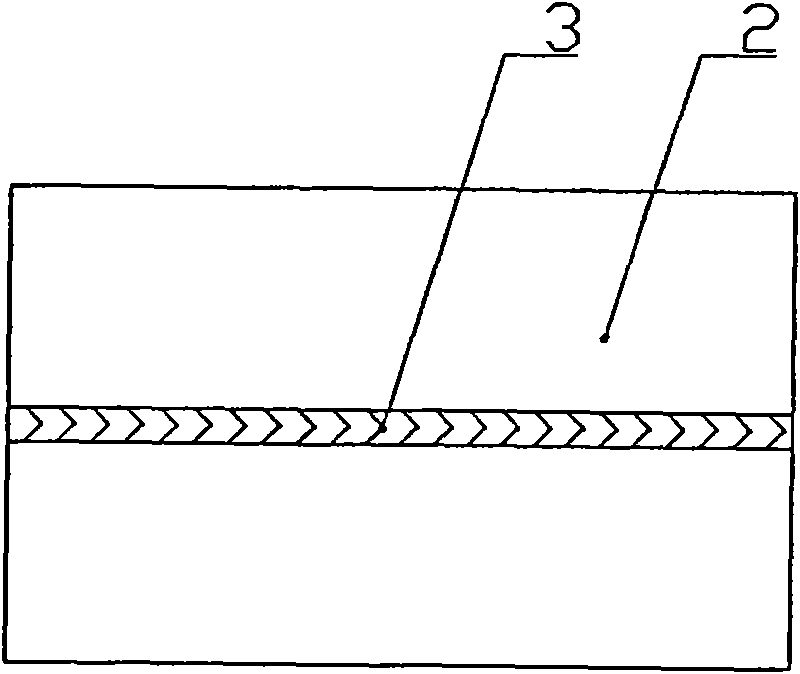

[0025] A copper-plated aluminum tube inner conductor for a coaxial cable, comprising a hollow aluminum alloy tube 1, the outer surface of the hollow aluminum alloy tube 1 is provided with a copper-plated layer 4 uniformly distributed along its longitudinal direction, and the copper-plated layer 4 is attached to the tube by electroplating The outer surface of the hollow aluminum alloy tube 1 .

[0026] The wall thickness of the hollow aluminum alloy tube 1 is 0.30 mm to 0.80 mm.

[0027] The thickness of the copper plating layer 4 is 0.04 mm to 0.06 mm.

[0028] The volume of the copper-plated layer 4 is 8% to 12% of the inner conductor of the copper-plated aluminum tube.

[0029] The inner conductor of the copper-coated aluminum tube has a density of 3.20 g / cm3 to 3.44 g / cm3.

[0030] The hollow aluminum alloy tube 1 can be processed by using the aluminum alloy profile t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com