SILICON BASED SOLID STATE LIGHTING and manufacturing method thereof

A light-emitting device and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of providing a substrate, not using a single crystal form, and damaging the light-emitting performance of the LED structure 100, so as to prevent layer fracture , increase luminous efficiency, and improve manufacturing throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

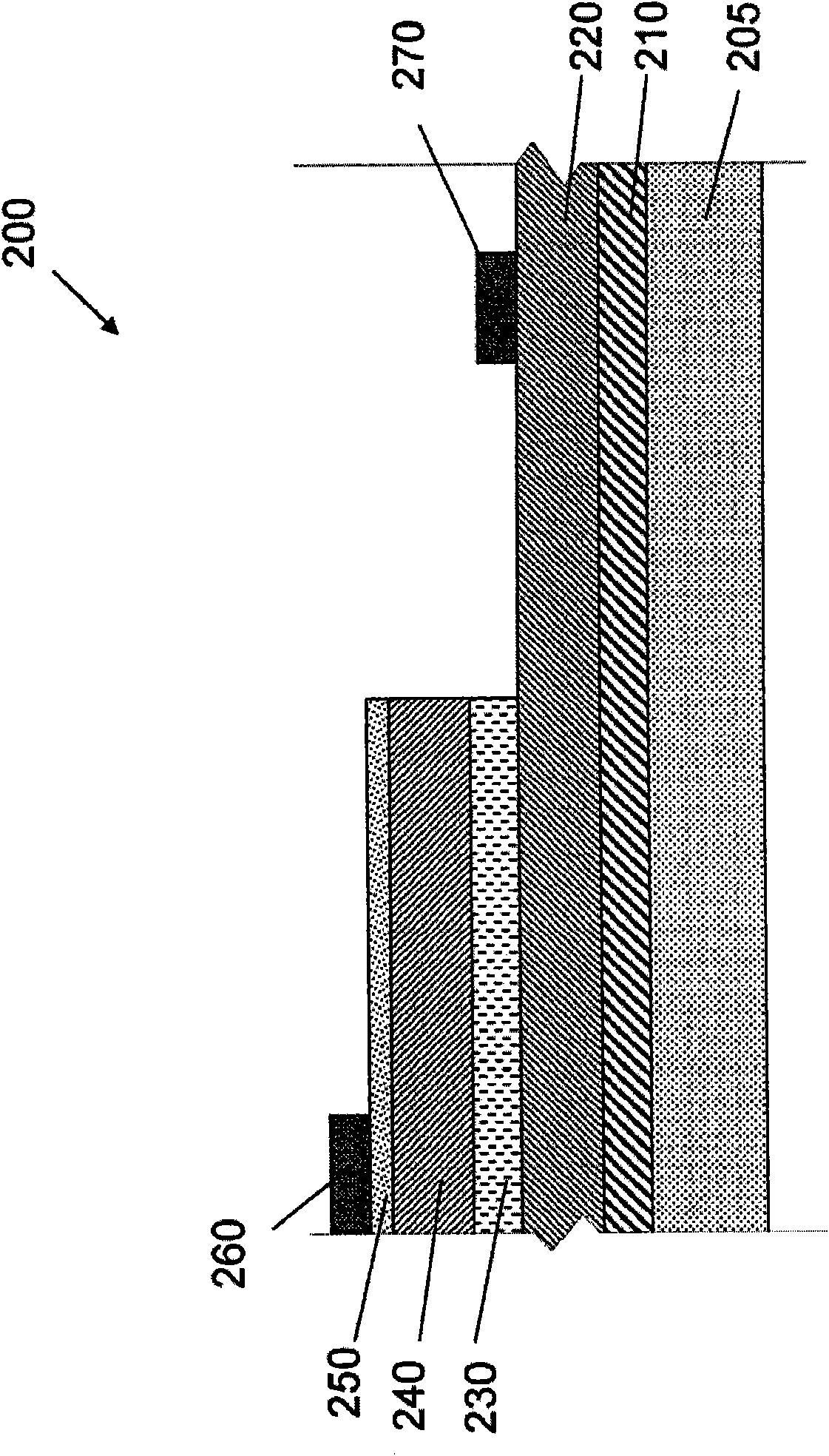

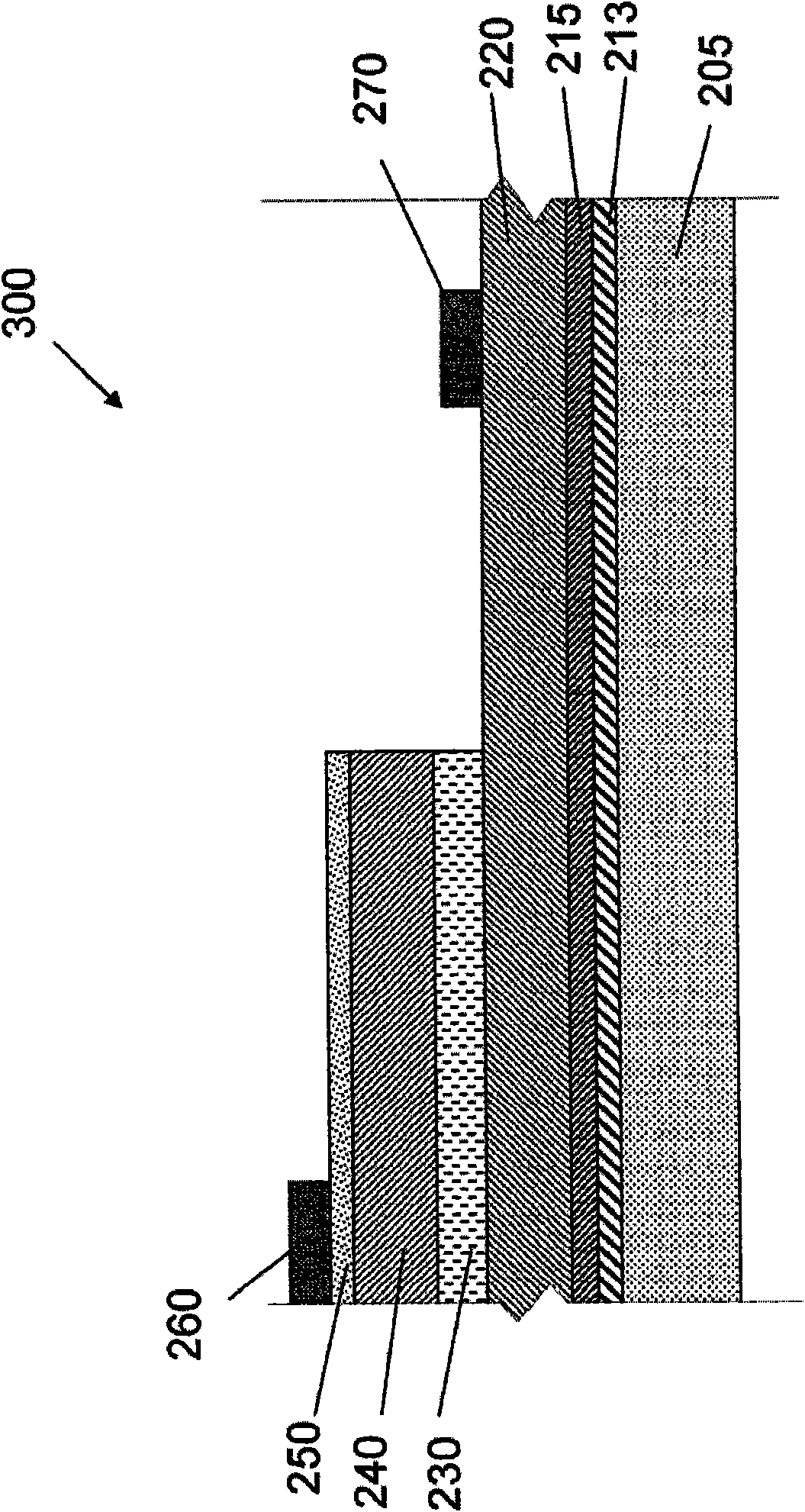

[0032] refer to figure 2 , the LED structure 200 includes a substrate 205 that may have an upper surface along a (111) or (100) crystallographic orientation. The substrate 205 may be formed of silicon, silicon oxide, or glass. For a silicon substrate, substrate 205 may include a (100) or (111) upper surface. Substrate 205 may also include a complementary metal oxide semiconductor (CMOS) material containing circuitry for driving and controlling LED structure 200 . A buffer layer (transition layer) 210 is formed on the substrate 205 . Preferably, the buffer layer 210 may include one or more optical reflective layers. The optical reflective layer may be a thin film formed of Al, Ag, Au or their oxides, or may be other multilayer metal reflective films. As another example, only one or more optical reflective layers may be formed on the substrate 205 without forming the buffer layer 210 . In addition, optionally, after one or more optical reflection layers are formed on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com