Method for synthesizing guaiacol

A technology of guaiacol and catechol, applied in organic chemistry, ether preparation and other directions, to achieve the effects of high yield, short process flow and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

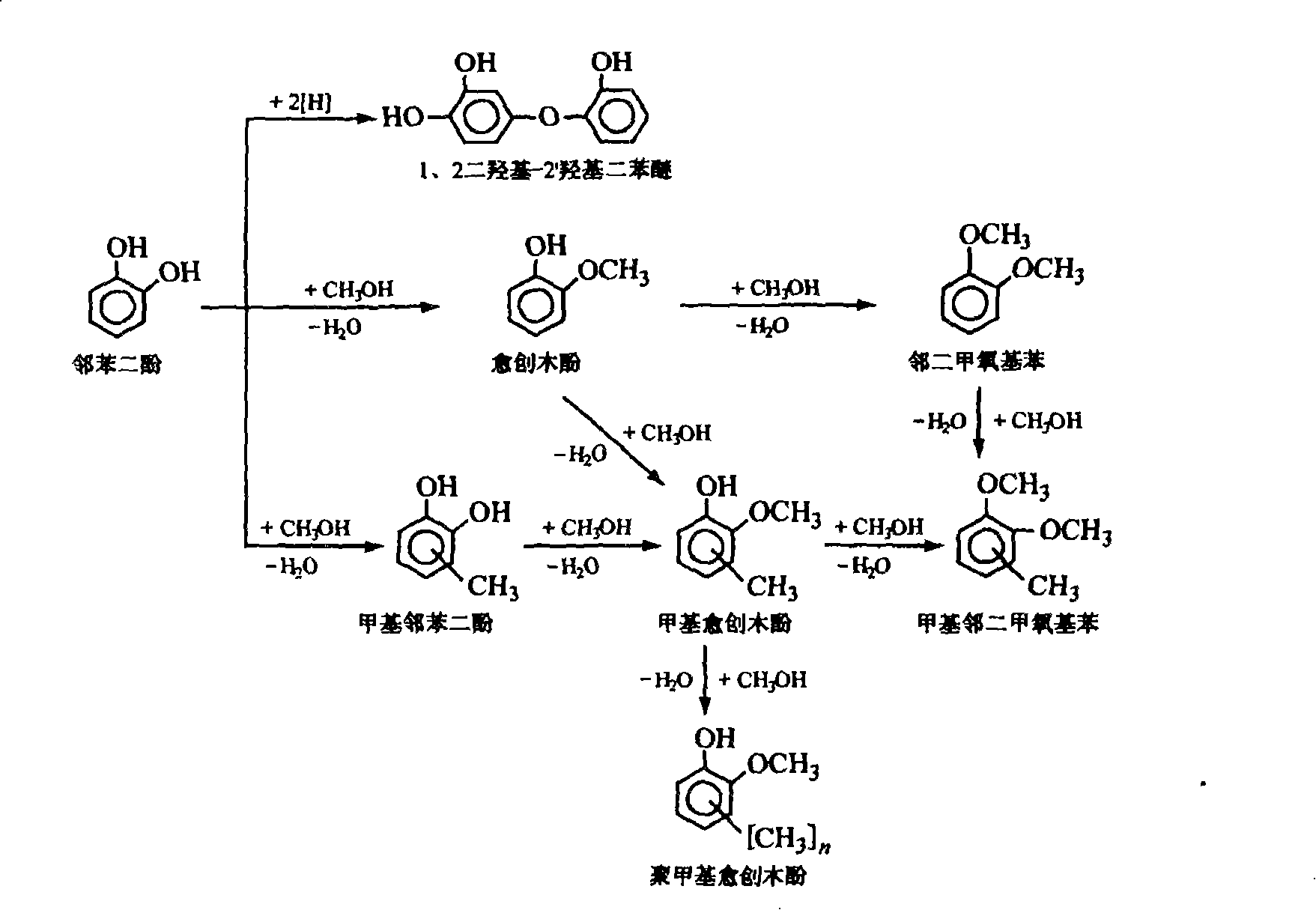

Problems solved by technology

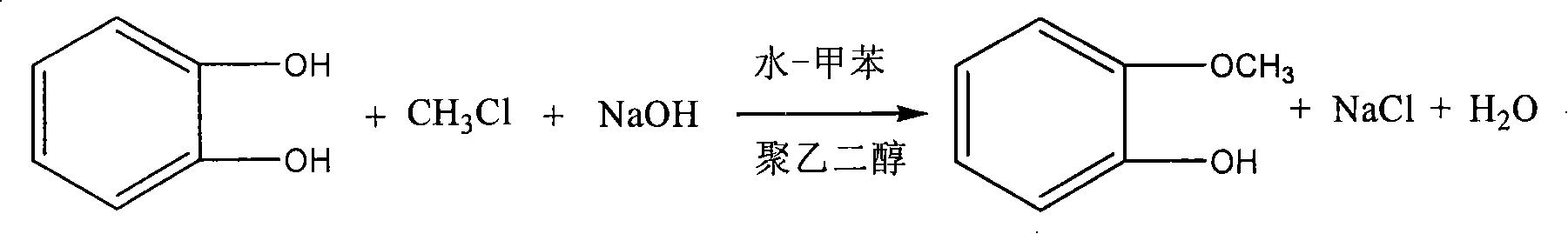

Method used

Image

Examples

Embodiment 1

[0020] 1) After adding 0.2mol catechol, polyethylene glycol-400, 0.18mol sodium hydroxide, 20ml water and 60ml toluene, which account for 1% of the catechol mass, into the reactor, fill it with 0.20mol methyl chloride gas, Stir, the temperature rises to 100°C within 30 minutes and react for 1 hour;

[0021] 2) Add 1:1 hydrochloric acid to the reaction solution in step 1) to adjust the pH=5 to 6, let stand for stratification, weigh the toluene phase, and obtain the yield of guaiacol by gas chromatography analysis is 70.00%, selectivity It was 87.64%, and the conversion rate of catechol was 79.83%.

Embodiment 2

[0023] 1) After adding 0.2mol catechol, polyethylene glycol-6000, 0.22mol sodium hydroxide, 20ml water and 60ml toluene, which account for 4% of catechol mass, into the reactor, fill it with 0.28mol methyl chloride gas, Stirring, the temperature rose to 140°C within 30 minutes and reacted for 4 hours;

[0024] 2) Add 1:1 hydrochloric acid to the reaction solution in step 1) to adjust the pH=5 to 6, let stand for stratification, weigh the toluene phase, and obtain the yield of guaiacol by gas chromatography analysis is 87.24%, selectivity It is 87.24%, and the conversion rate of catechol is 100%.

Embodiment 3

[0026] 1) After adding 0.2mol catechol, polyethylene glycol-6000, 0.22mol sodium hydroxide, 20ml water and 60ml toluene, which account for 5% of catechol mass, into the reactor, fill it with 0.28mol methyl chloride gas, Stirring, the temperature rose to 140°C within 30 minutes and reacted for 4 hours;

[0027] 2) Add 1:1 hydrochloric acid to the reaction solution in step 1) to adjust the pH=5 to 6, let stand for stratification, weigh the toluene phase, and obtain the yield of guaiacol by gas chromatography analysis is 79.81%, selectivity is 85.52%, and the conversion rate of catechol is 93.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com