Preparation method of halogen-free environmental protection flame-retardant asphalt for tunnel road surface

A kind of asphalt, environmental protection technology, applied in the direction of roads, roads, building insulation materials, etc., to delay the fire, reduce smoke, improve the effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

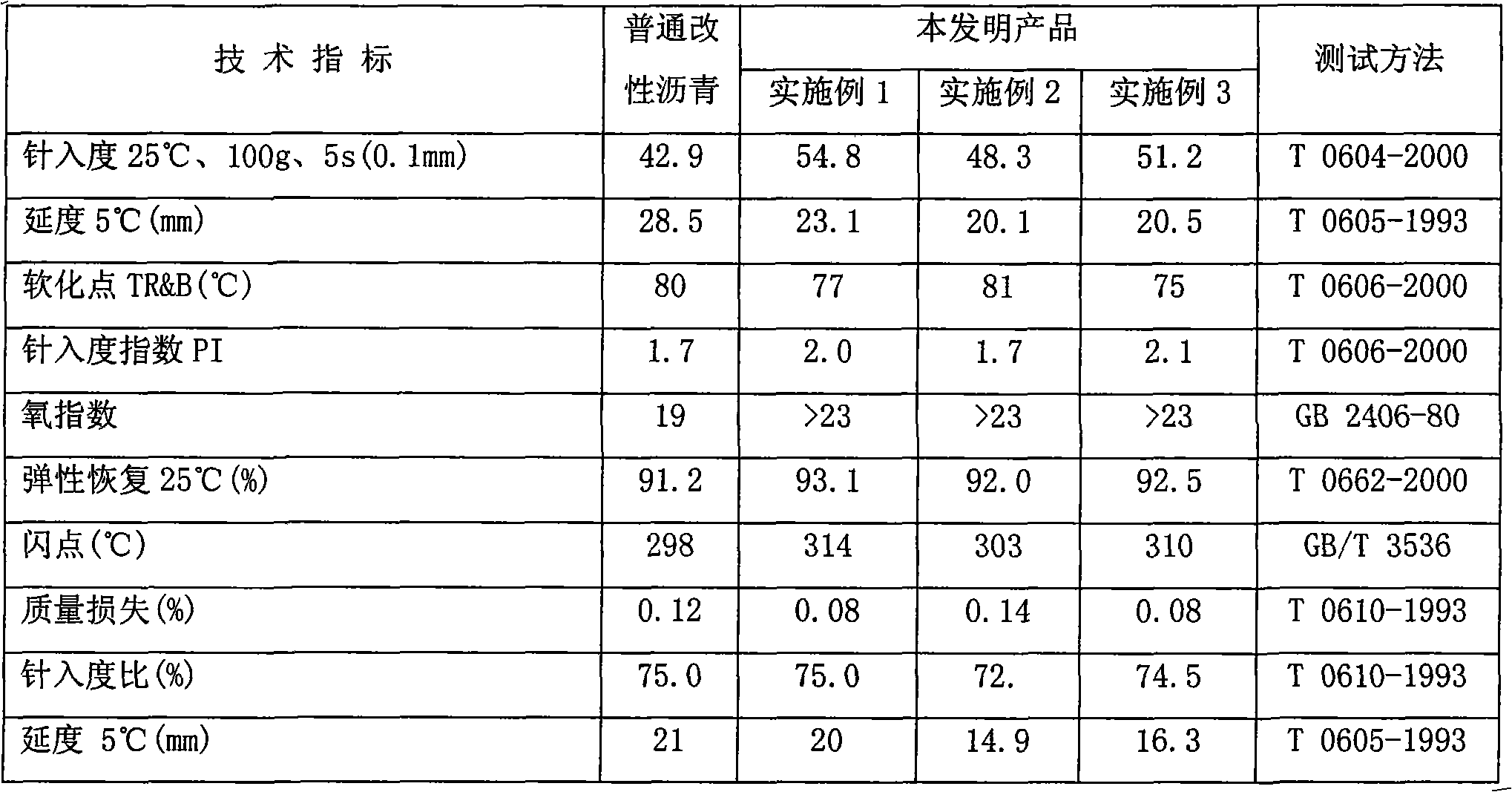

Examples

Embodiment 1

[0025] The group allocation ratio is as follows:

[0026] Component mass percentage is (%)

[0027] Zhonghai No. 70 asphalt 91

[0028] SBS modifier 6

[0029] Halogen-free flame retardant 3

[0030] Wherein, the mass percent of each component of flame retardant is:

[0031] Component mass percentage is (%)

[0032] Melamine Phosphonate 50

[0034] KH-570 9.5

[0035] Molybdenum trioxide 0.5

[0036] According to the above-mentioned raw material proportioning, prepare according to the following process:

[0037] Step 1: Heat the Zhonghai No. 70 asphalt in the asphalt storage tank to 110°C by circulating heating oil, and dehydrate it at a constant temperature for 50 minutes.

[0038] Step 2: Heat up to 170°C, stir and shear at a speed of 1000r / min, and add SBS modifier at the same time. After the SBS modifier is completely submerged in the asphalt, the stirring speed is increased to 4000r / min, and the constant temperature is sheared for...

Embodiment 2

[0041] The group allocation ratio is as follows:

[0042] Component mass percentage is (%)

[0043] Zhonghai No. 70 asphalt 75

[0044] SBS modifier 5

[0045] Halogen-free flame retardant 20

[0046] Wherein, the mass percent of each component of flame retardant is:

[0047] Component mass percentage is (%)

[0048] Ammonium polyphosphate 75

[0050] KH-550 3

[0051] Molybdenum trioxide 2

[0052] The preparation method is the same as in Example 1.

Embodiment 3

[0054] The group allocation ratio is as follows:

[0055] Component mass percentage is (%)

[0056] Zhonghai No. 70 asphalt 60

[0057] SBS modifier 30

[0058] Halogen-free flame retardant 10

[0059] Wherein, the mass percent of each component of flame retardant is:

[0060] Component mass percentage is (%)

[0061] Melamine 60

[0063] KH-550 8

[0064] Molybdenum trioxide 2

[0065] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com