Antiflaming puncture-resisting water-proof sheet and manufacturing method thereof

A waterproof sheet, anti-puncture technology, used in mining equipment, shaft equipment, earth-moving drilling and other directions, can solve the problem that the anti-puncture waterproof sheet cannot be flame retardant and fireproof, and achieve excellent puncture resistance, large friction coefficient, deformation adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Composite Flame Retardant Masterbatch

[0032] formula:

[0033] Carrier resin (low density polyethylene) 10 parts

[0034] Decabromodiphenyl ether 64 parts

[0035] Antimony trioxide 19.5 parts

[0036] Chlorinated paraffin-70 5 parts

[0037] 0.7 parts of silane coupling agent

[0038] Light stabilizer (ultraviolet absorber UV531) 0.2 parts

[0039] Antioxidant 1010 0.2 parts

[0040] Zinc stearate 0.4 parts

[0041] Preparation:

[0042] Put the decabromodiphenyl ether main flame retardant and antimony trioxide measured according to the formula into a high-speed mixer and stir at a high speed to 35°C ± 2°C, and stir for about 5 minutes. Then put low-density polyethylene, chlorinated paraffin-70, coupling agent, light stabilizer, antioxidant and lubricant into a high-speed mixer and stir at a high speed to 95°C±2°C for about 30 minutes. When there is no dust, mix The final material is added to a twin-screw extruder with an aspect ratio of 44. T...

Embodiment 2

[0044] formula:

[0045] Carrier resin (low density polyethylene) 8 parts

[0046] Decabromodiphenyl ether 70 parts

[0047] 12 parts of antimony trioxide

[0048] Chlorinated paraffin-70 8 parts

[0049] 0.7 parts of coupling agent (titanate)

[0050] Light stabilizer (ultraviolet absorber UV531) 0.4 parts

[0051] Antioxidant (antioxidant 1010) 0.3 parts

[0052]0.6 parts of lubricant (stearic acid)

[0053] The preparation method is the same as in Example 1.

Embodiment 3

[0055] formula:

[0056] Puncture-resistant waterproof sheet material 83kg

[0057] Composite flame retardant masterbatch 14kg

[0058] Other additives 3kg

[0059] Other additives: coupling agent (titanate coupling agent) 1kg, light stabilizer (ultraviolet absorber UV531) 0.5kg, antioxidant (antioxidant 1010) 0.5kg, and lubricant (stearic acid) 1kg ;

[0060] Preparation:

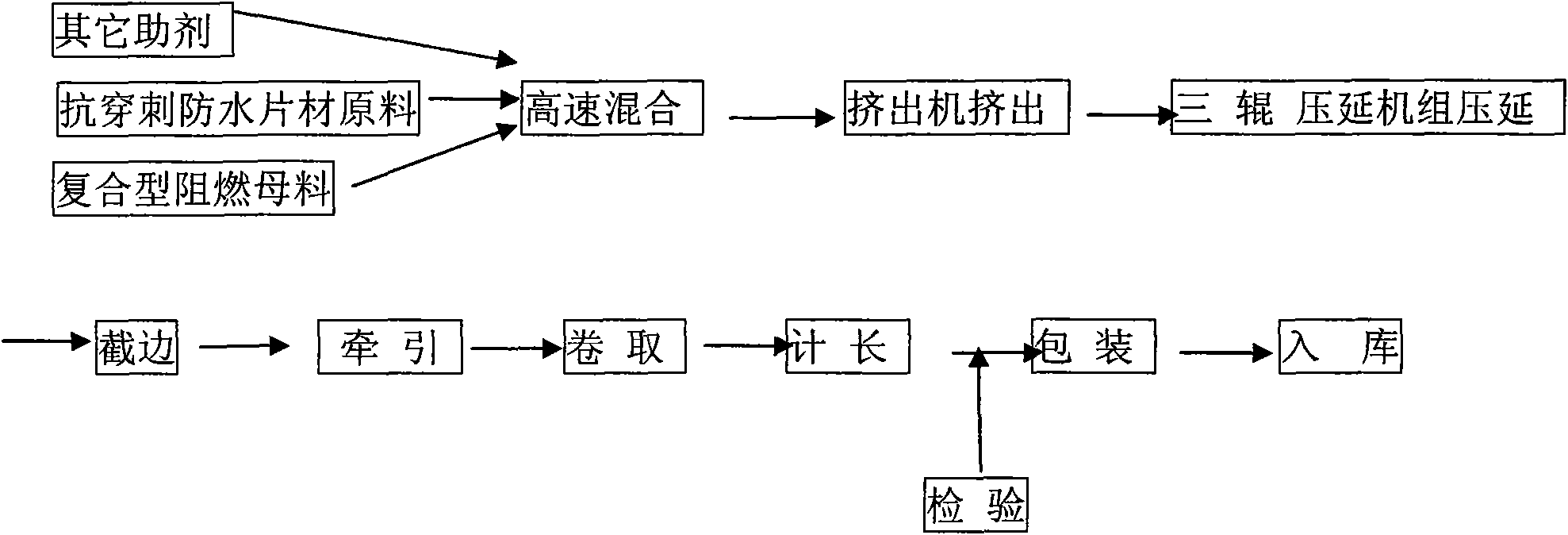

[0061] Measure all the raw materials according to the formula requirements and put them into the high-speed mixer for uniform mixing, then put the uniformly mixed materials into the hopper of the extruder, and carry out extrusion and calendering according to the process described in the attached drawing of the manual to make ZLECB waterproof sheet material. The processing temperature of each section of extruder barrel and hanger die lip is as follows:

[0062] Cylinder: Zone 1, Zone 2, Zone 3, Zone 4, Zone 5, Zone 6, Zone 7, Flange

[0063] 140°C 150°C 155°C 160°C 165°C 175°C 185°C 175°C

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com