Flexible bonding copper wire and preparation method thereof

A flexible bond and copper wire technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as excessive copper wire, reduce impact force and damage, reduce bonding energy, and maintain stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Raw material ratio: Ce 0.001%, Pd 0.005%, Pt 0.005%, with Cu to 100%.

[0019] Preparation:

[0020] 1) Alloy: Select the alloy elements to be added, and use more than 99.999% high-purity copper to make pre-alloys and master alloys.

[0021] 2) Melting and casting: According to different models and customer requirements, 99.999% high-purity copper is added to various alloys, cast into round rods, and the crystal size can be obtained by adjusting the parameters such as the speed of drawing and casting, the temperature of heating and cooling Suitable, uniformly structured rods;

[0022] 3) Wire drawing: the gold rod is drawn into wires of different diameters through a wire drawing machine, and the appropriate processing deformation is selected to prevent recovery and recrystallization softening.

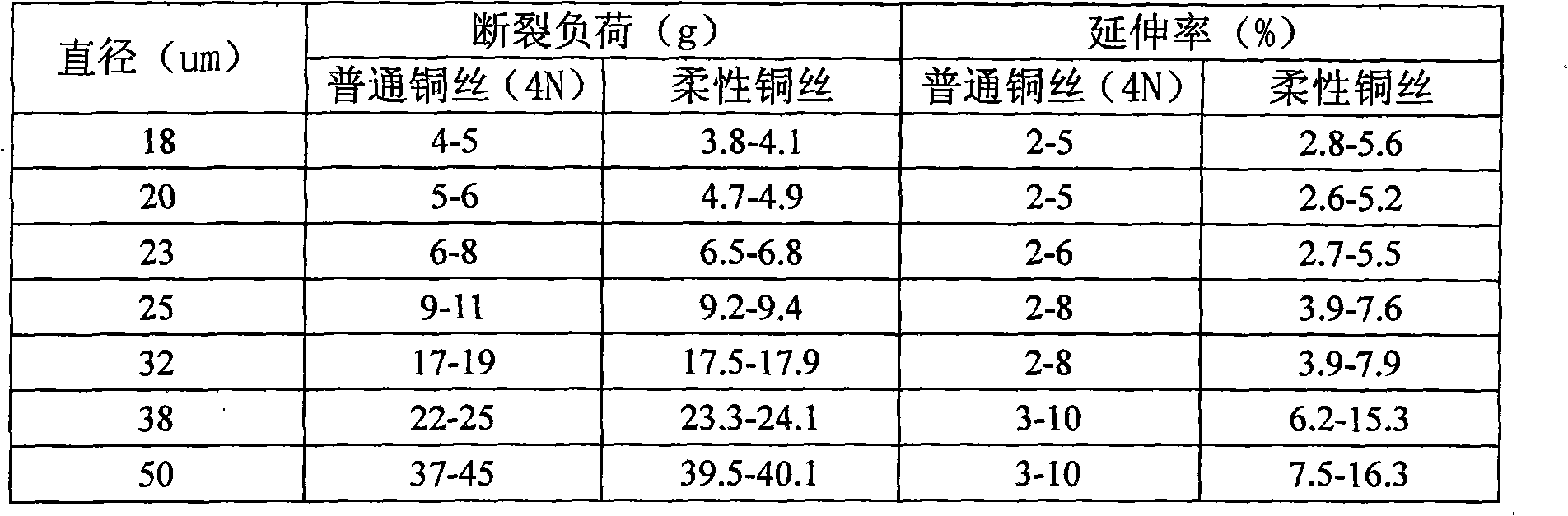

[0023] 4) Annealing: According to different requirements of customers, set different annealing parameters, eliminate stress, select recrystallization area, and obtain mechanic...

Embodiment 2

[0028] Raw material ratio: Ce 0.005%, Pd 0.003%, Pt 0.009%, with Cu to 100%.

[0029] Preparation method: with embodiment one.

Embodiment 3

[0031] Raw material ratio: Ce 0.003%, Pd 0.004%, Pt 0.007%, with Cu to 100%.

[0032] Preparation method: with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com