Hydrogel tissue filling agent for ophthalmology and preparation method thereof

The technology of hydrogel and filler is applied in the field of ophthalmic hydrogel tissue filler and its preparation, which can solve the problems of low volume swelling and inability to meet the requirements, achieve good tolerance and biocompatibility, and reduce complications Symptoms, excellent swelling ability and the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The bulk polymerization method is adopted, with AIBN as the initiator, allyl MA and EGDM as the crosslinking agent, and NVP and MMA as the monomers to carry out the copolymerization reaction. The total raw material weight is 4g, the monomer composition is NVP / MMA=75 / 25, the amount of crosslinking agent allyMA / EGDM=0.19% / 0.026%, and the amount of initiator is 0.05%. In the triangular grinding mouth flask, according to the predetermined ratio, dissolve the initiator and cross-linking agent in NVP, then add MMA, stir to make all components mix completely. The monomer mixture was filtered, the filtrate was poured into a mold, and reacted in a constant temperature incubator at 80° C. for 24 hours.

[0025] (2) Take the sample synthesized in step (1), fully swell in physiological saline for 72 hours, place in a container with 20% NaOH solution (about 20ml), and react at a constant temperature at 70°C for 1 hour.

[0026] (3) Take the sample treated in step (2), wash it i...

Embodiment 2

[0028](1) The bulk polymerization method is adopted, with BPO as the initiator, allyl MA and EGDM as the crosslinking agent, and NVP and MMA as the monomers to carry out the copolymerization reaction. The total raw material weight is 4g, the monomer composition is NVP / MMA=80 / 20, the crosslinking agent addition allyMA / EGDM=0.38% / 0.052%, and the initiator dosage is 0.2%. In the triangular grinding mouth flask, according to the predetermined ratio, dissolve the initiator and cross-linking agent in NVP, then add MMA, stir to make all components mix completely. The monomer mixture was filtered, and the filtrate was poured into a mold, and reacted in a constant temperature incubator at 90° C. for 12 hours.

[0029] (2) Take the sample synthesized in step (1), fully swell in saline for 72 hours, place it in a container with 30% NaOH solution (about 20ml), and react at a constant temperature at 80°C for 4 hours.

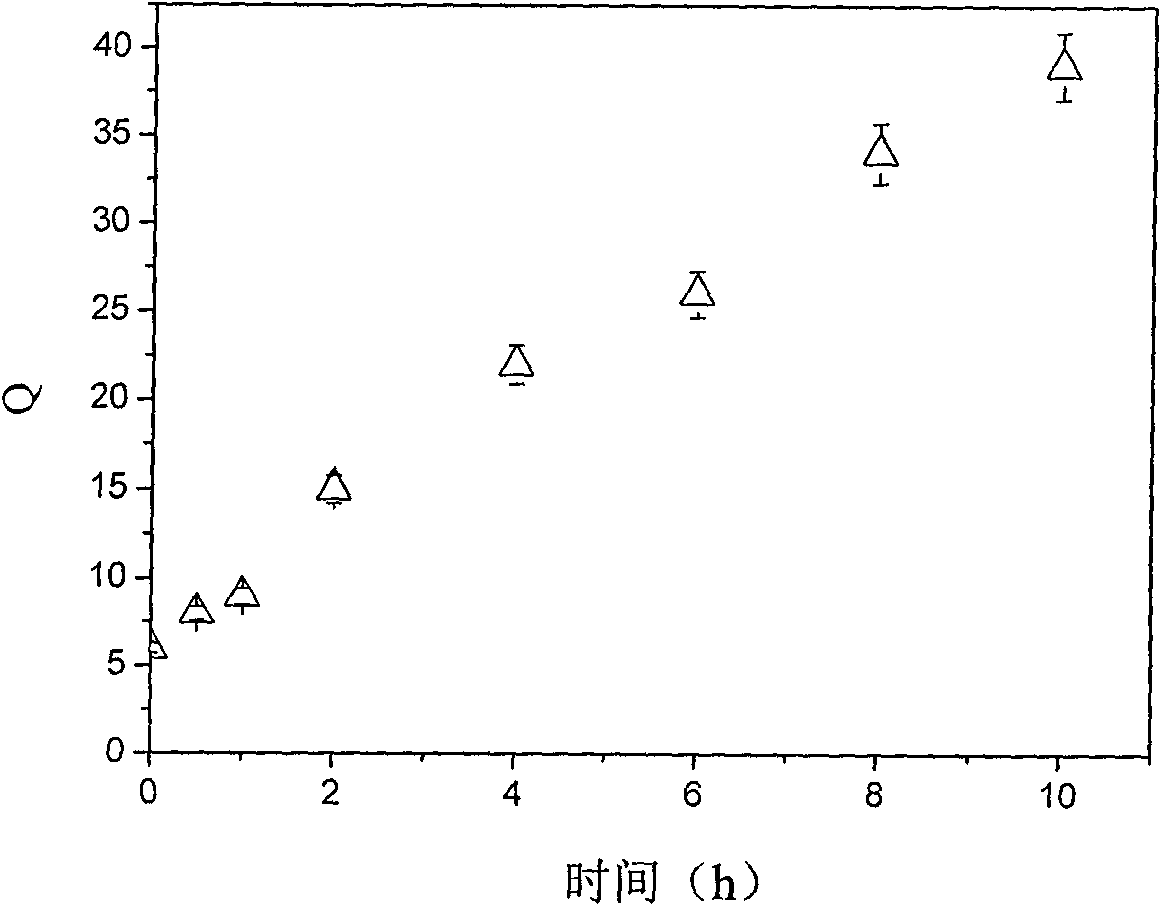

[0030] (3) With step (3) in embodiment 1. The volume swelling degree ...

Embodiment 3

[0032] (1) The bulk polymerization method is adopted, with AIBN as the initiator, allyl MA and EGDM as the crosslinking agent, and NVP and MMA as the examples to carry out the copolymerization reaction. The total raw material weight is 4g, the monomer composition is NVP / MMA=65 / 35, the amount of crosslinking agent added is allyMA / EGDM=0.19% / 0.026%, and the amount of initiator is 0.08%. In the triangular grinding mouth flask, according to the predetermined ratio, dissolve the initiator and cross-linking agent in NVP, then add MMA, stir to make all components mix completely. The monomer mixture was filtered, and the filtrate was poured into a mold, and reacted in a constant temperature incubator at 80° C. for 24 hours.

[0033] (2) Take the sample synthesized in step (1), fully swell in normal saline for 72 hours, place it in a container with 10% NaOH solution (about 20ml), and react at a constant temperature at 60°C for 10 hours.

[0034] (3) With step (3) in embodiment 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com