Naphthalene-containing polyetherimide polymer and preparation method thereof

A naphthalene polyetherimide and polymer technology, which is applied in the field of polyetherimide preparation, can solve the problem of low heat resistance, and achieve the effects of improving cost performance, large market and development prospects, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

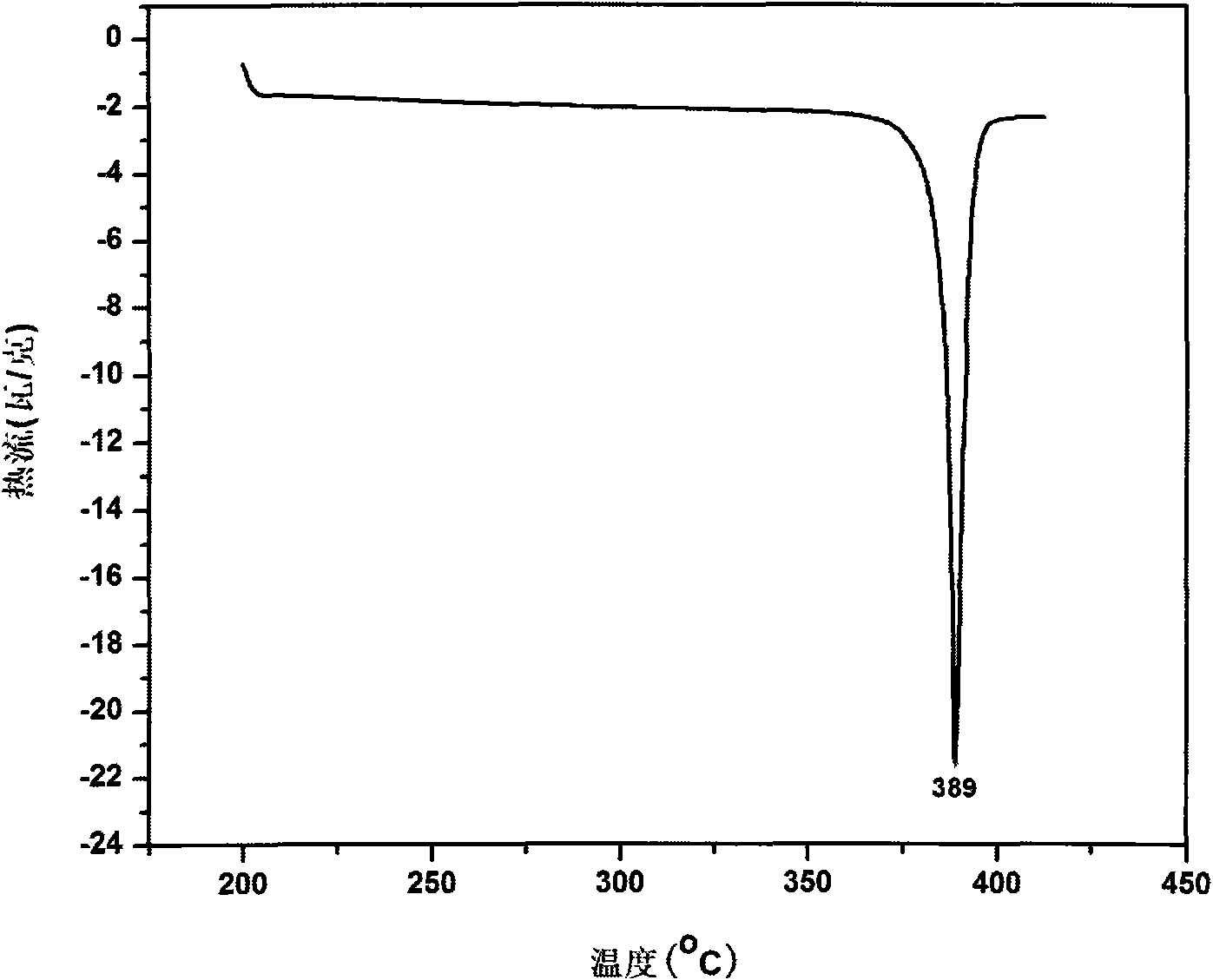

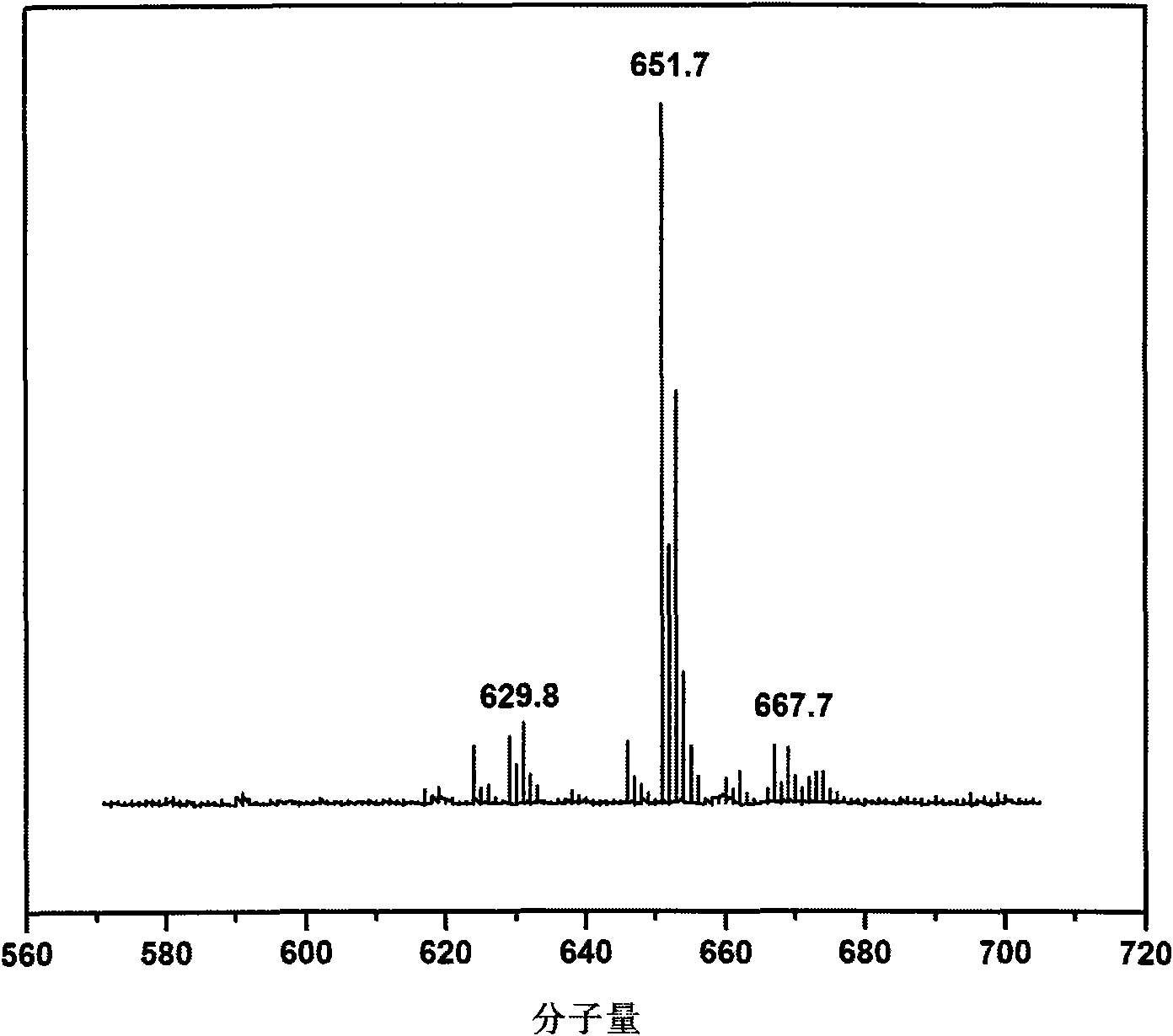

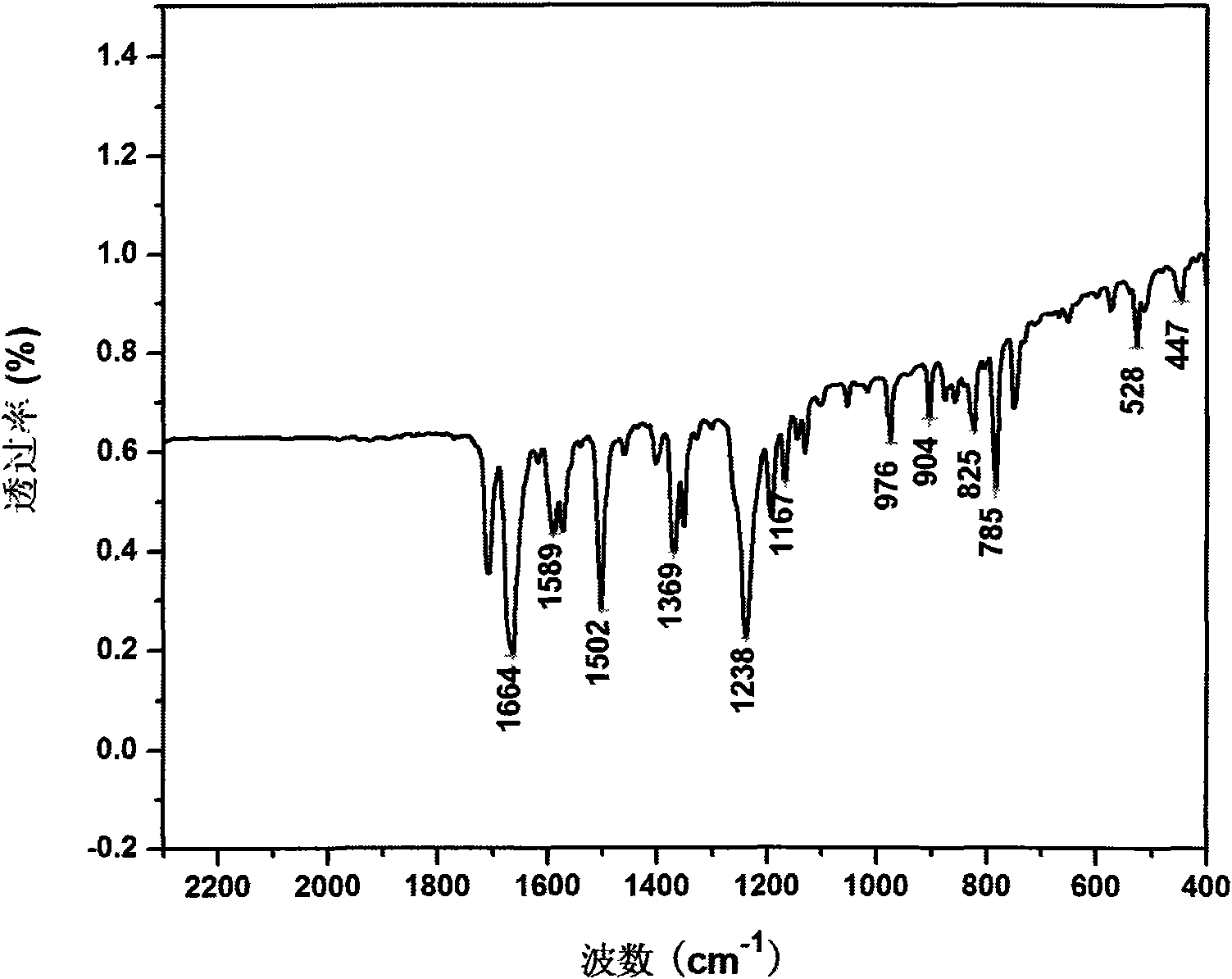

Embodiment 1

[0055] Atmospheric pressure (1.01×10 5 Pa) under, equipped with stirrer, condenser, water trap, thermometer, argon (argon gas is fed from the beginning of the experiment to the end of the experiment. The aforementioned reflux water device refers to the condenser and the separator here. Add 4.69g (0.02mol) 4-chloro-1,8-naphthalene anhydride, 2.00g (0.01mol) 4,4'-diaminodiphenyl ether, 40ml N,N -Dimethylacetamide (DMAc), 10ml of xylene, stirred at room temperature for 1 hour, then started to heat slowly, maintained at 150°C with water for 2 hours, and the system was reddish brown at this time. After the water is completely carried out, xylene is released, and then the temperature of the reaction system is raised to 160°C for 6 hours. After the reaction was completed, the solid was filtered out, then washed twice with acetone and ethanol to remove the residual solvent, and finally the obtained solid was dried in vacuum at 60°C for 5 hours to obtain 3.6 g of golden yellow solid p...

Embodiment 2

[0057] Atmospheric pressure (1.01×10 5 Pa), add 97.7g (0.4mol) 4-chloro-1,8-naphthalene anhydride, 40.0g (0.2 mol) 4,4'-diaminodiphenyl ether, 500ml N,N-dimethylacetamide (DMAc), 70ml xylene, stirred at room temperature for 1 hour, began to heat slowly, and maintained at 150°C with water for 6h, at this time The system is reddish brown. Wait for the water to be completely released, xylene is released, and the temperature is raised to 160°C for 12 hours. After the reaction was completed, the precipitated solid was filtered, then washed twice with acetone and ethanol to remove the residual solvent, and finally the obtained solid was dried in vacuum at 60°C for 15 hours to obtain 81.2 g of golden yellow solid powder, with a yield of 66.0%. (Monomer 1, name: 4,4'-bis(N-phenyl-4-chloro-1,8-naphthalimide) ether), higher than the yield of Example 1.

Embodiment 3

[0059] Atmospheric pressure (1.01×10 5 Pa), add 4.69g (0.02mol) 4-chloro-1,8-naphthalene anhydride, 1.08g (0.01 mol) p-phenylenediamine, 30ml N,N-dimethylacetamide (DMAc), 8ml xylene, stirred at room temperature for 1 hour, started to heat slowly, maintained at 150°C with water for 2 hours, and the system was reddish brown at this time. Wait for the water to be completely released, xylene is released, and the temperature is raised to 160°C for 8 hours. After the reaction was completed, the precipitated solid was filtered, then washed twice with acetone and ethanol to remove the residual solvent, and finally the obtained solid was dried in vacuum at 60° C. for 5 h to obtain 2.7 g of golden yellow solid powder (monomer 2, Name: 4,4'-bis(4-chloro-1,8-naphthalimide)benzene), yield 50.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com