Comprehensive process technology of solid waste in alumina plant

A solid waste and comprehensive treatment technology, which is applied in the field of solid waste treatment process of Bayer process alumina production, can solve the problems of alkali adverse effects, land occupation, high cost, etc., so as to alleviate the pressure of environmental protection, realize waste recycling and Environmental friendliness and remarkable benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

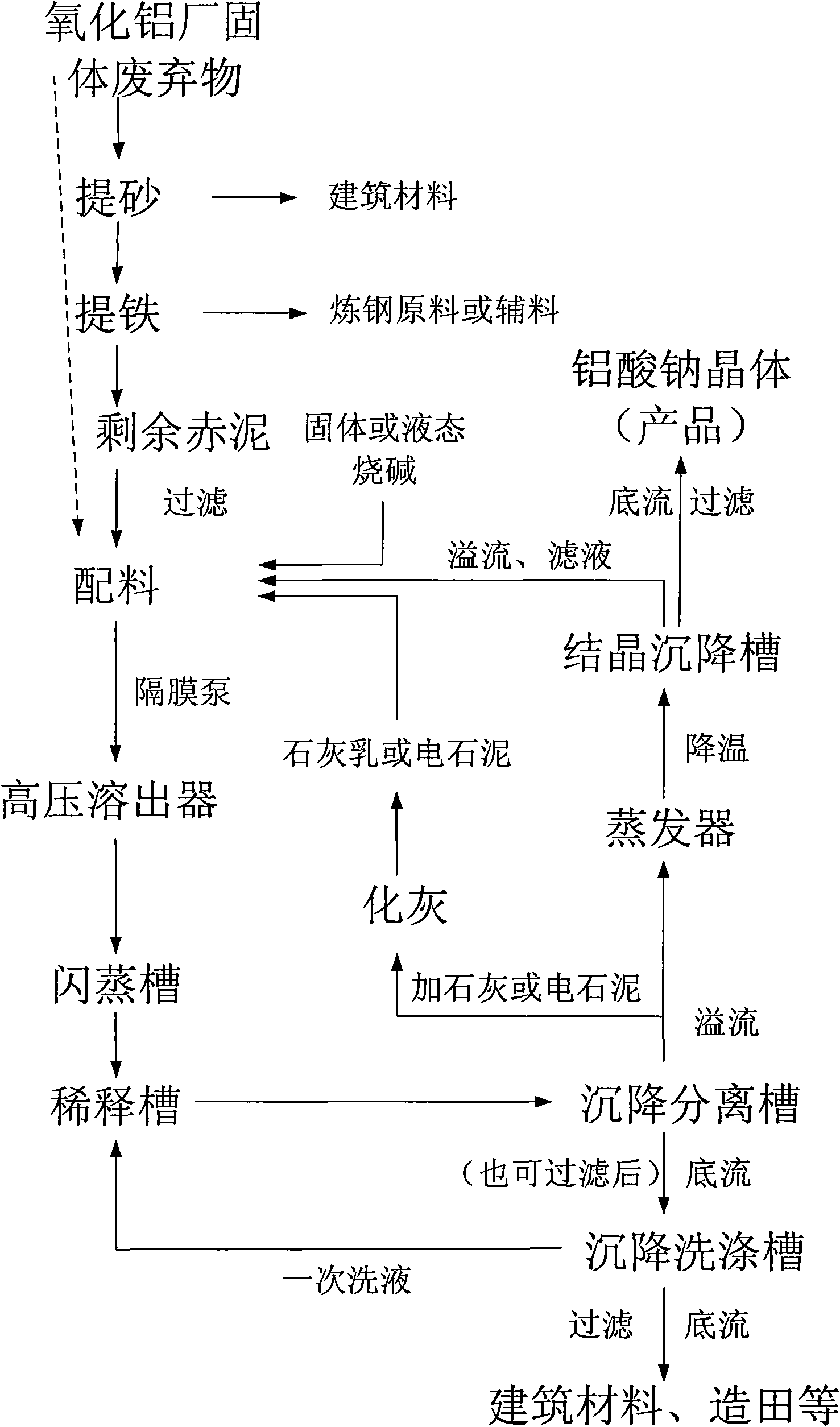

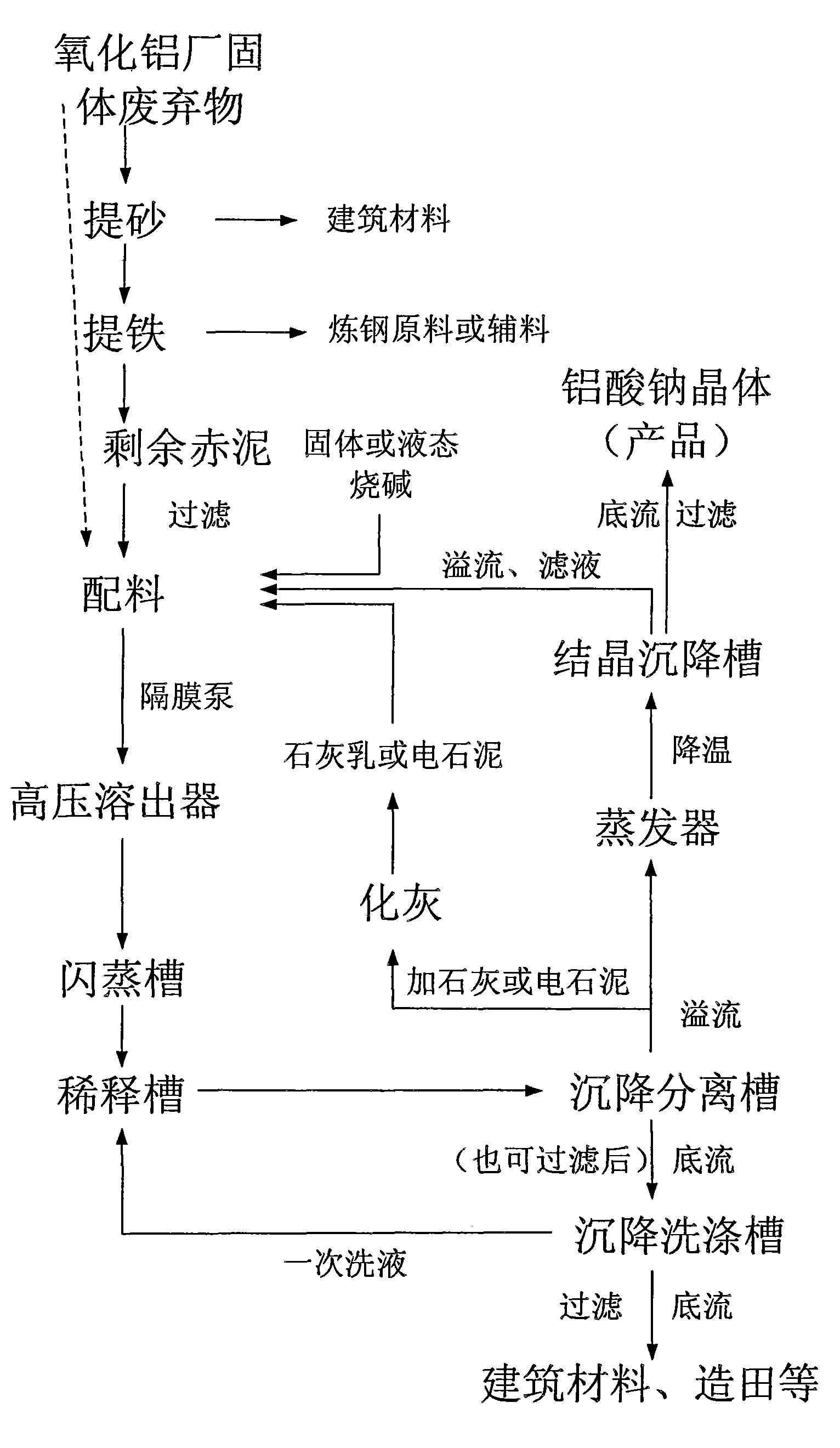

[0019] Comprehensive treatment process of solid waste in alumina plant:

[0020] (1) Pump the last underflow red mud from the sedimentation process in the alumina production process to the sand extraction and iron extraction process to extract sand and iron from solid waste; gravity separation is used for sand extraction, and gravity or magnetization separation is used for iron extraction Filter the treated solid waste to remove the moisture in the solid waste, and mix the obtained filter cake with solid or liquid caustic soda, the overflow of the crystallization settling tank obtained in the subsequent steps, and calcium carbide mud or milk of lime in the batching tank The caustic ratio of the final batching slurry is controlled to 20 to 30 to ensure that the caustic ratio of the eluate is 8 to 15, and the mass fraction ratio (C / S) of calcium oxide and silicon dioxide in the dissolved solid waste is 2.0 to 3.5;

[0021] (2) Pump the batching slurry into high-pressure dissolut...

Embodiment 2

[0025] Comprehensive treatment process of solid waste in alumina plant:

[0026] The operation is the same as in Example 1, except that step (3) the temperature of the stripper is 300-305° C., and the holding time is 40 minutes.

Embodiment 3

[0028] Comprehensive treatment process of solid waste in alumina plant:

[0029] The operation is the same as in Example 1, except that step (3) the temperature of the stripper is kept at 290 to 300° C., and the time of the soak is 50 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com