Composite membrane counter electrode used for dye-sensitized solar cells and preparation method thereof

A solar cell and dye sensitization technology, applied in the field of carbon material/polypyrrole composite film counter electrode and its preparation, can solve the problem of high preparation cost of platinum counter electrode, and achieve strong electrochemical reversibility, not easy to fall off, and high catalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

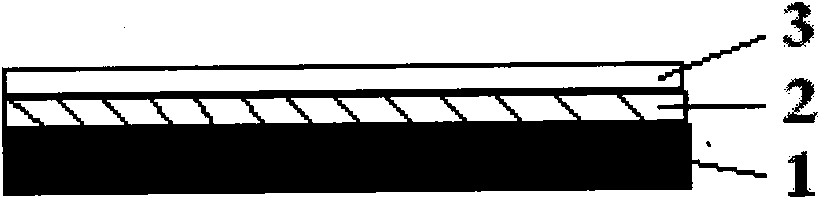

[0018] Embodiment 1: In this embodiment, a composite film counter electrode for dye-sensitized solar cells is sequentially composed of a conductive substrate (1), a carbon material film (2) and a polypyrrole film (3) through the intermolecular The polypyrrole film is a polypyrrole film or a polypyrrole derivative film.

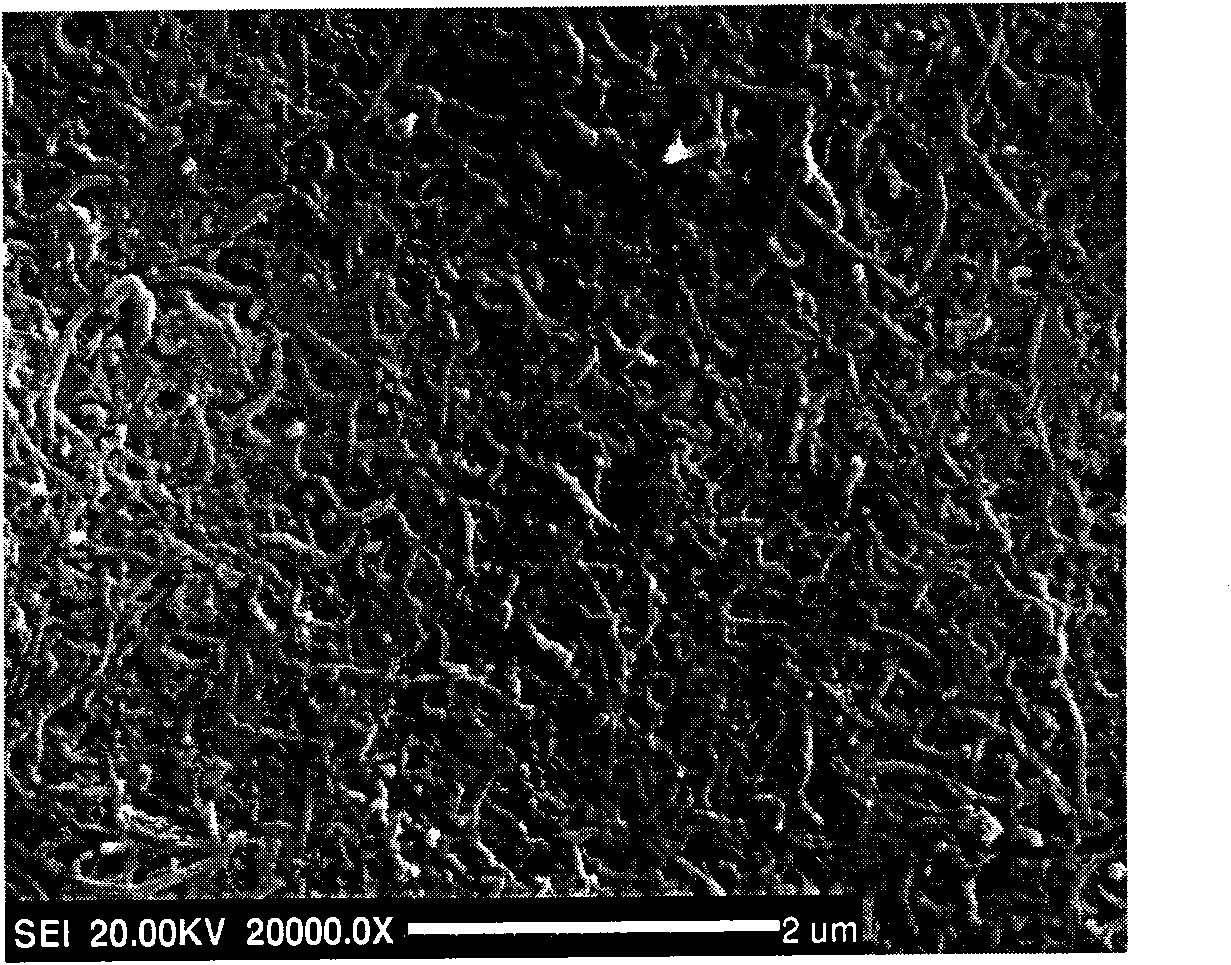

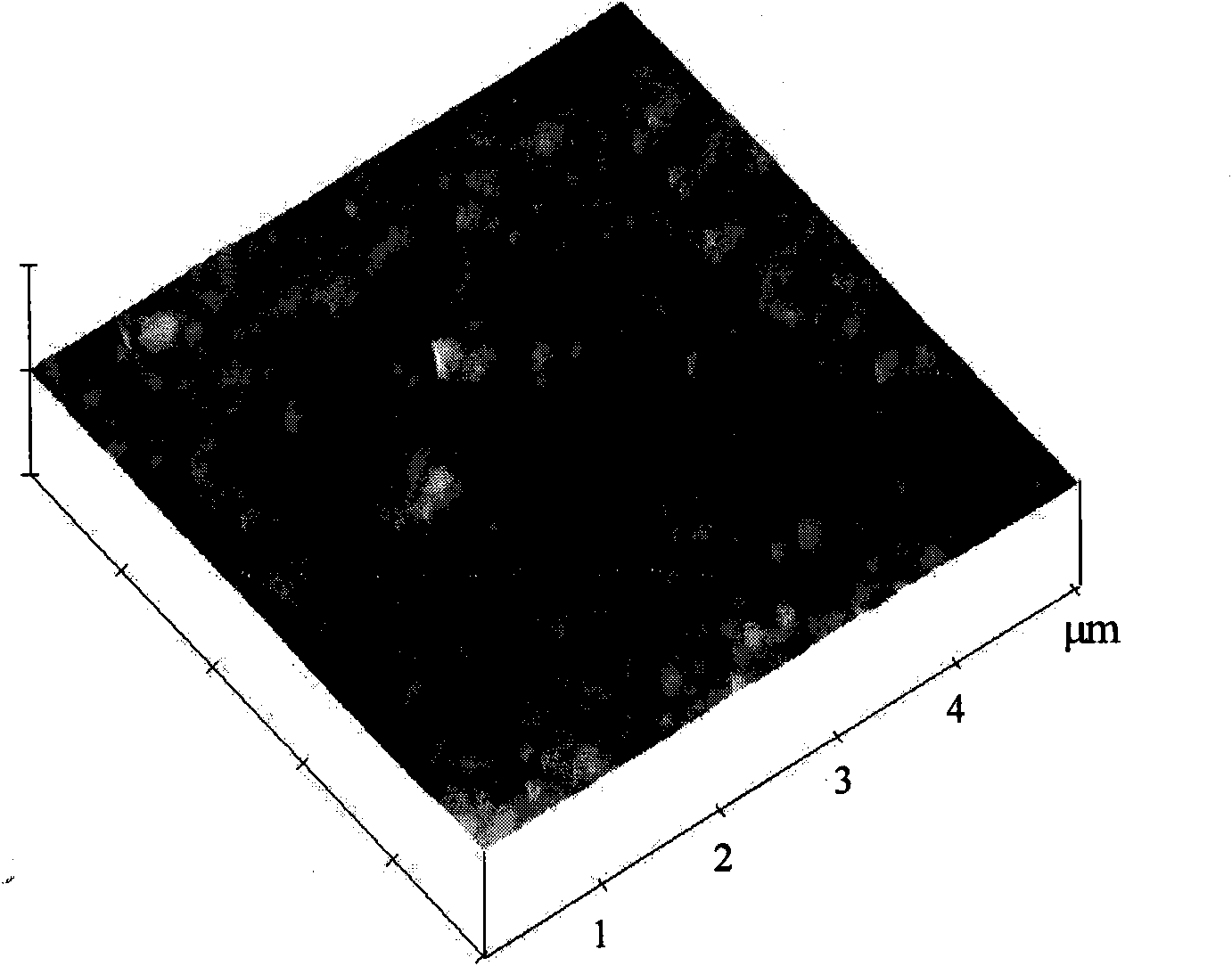

[0019] The structural schematic diagram of the composite film counter electrode used in the dye-sensitized solar cell of the present embodiment is as follows figure 1 shown. The composite film for dye-sensitized solar cells has a dense and uniform counter-electrode structure, strong bonding between adjacent layers, long service life, good stability, good catalytic performance, and controllable size. The photoelectric conversion efficiency of the dye-sensitized solar cell based on the carbon material and the polypyrrole composite film counter electrode of this embodiment reaches 4.267%, which can reach a level comparable to that of the existing conventional Pt...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the carbon material film is 6-10 μm, and the thickness of the polypyrrole film is 2-4 μm. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the conductive substrate is selected from conductive glass, stainless steel metal sheet or insulating material coated with a conductive metal film. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

[0022] The conductive metal described in this embodiment is copper, nickel, zinc, titanium or tin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com