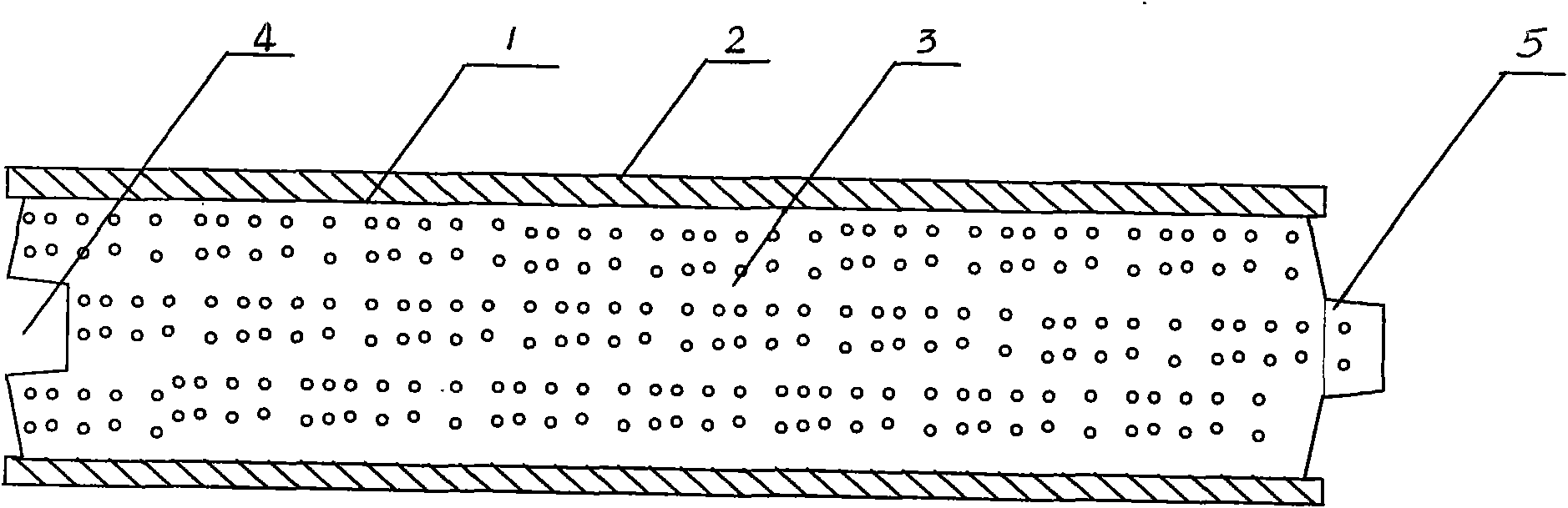

Light-weight insulating wall body and production method thereof

A thermal insulation wall, lightweight technology, applied in chemical instruments and methods, walls, building components, etc., can solve the problems of no patent application, no thermal insulation wall materials have been reported in reports, etc. Social and environmental effects, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

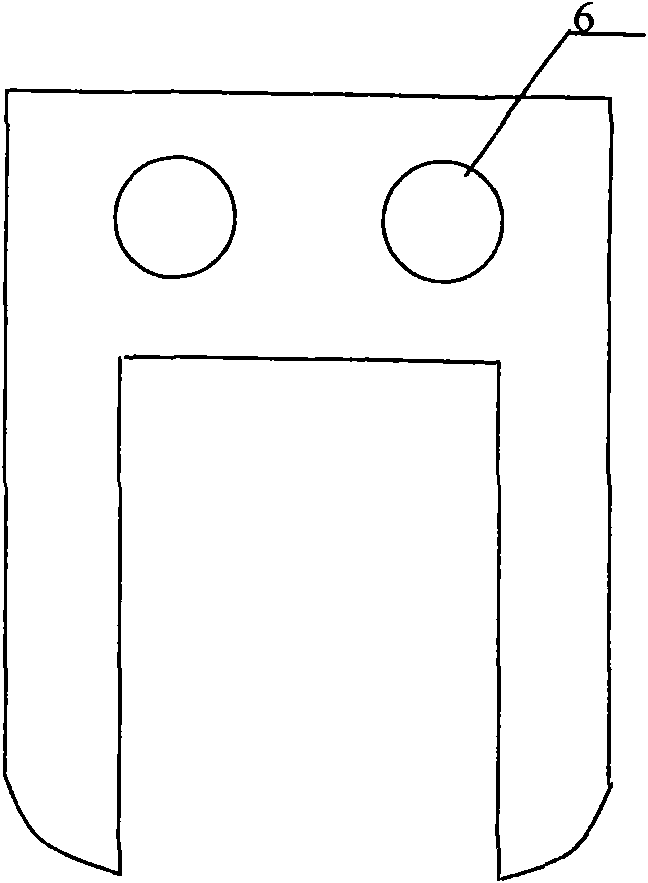

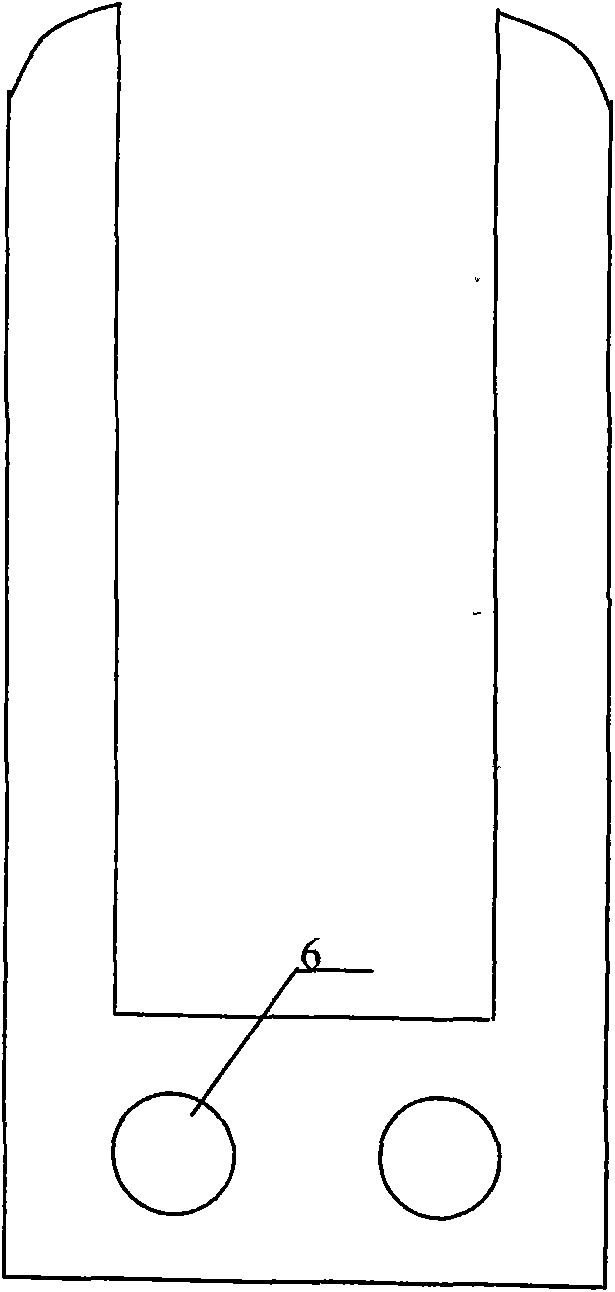

Image

Examples

Embodiment

[0033] The first step is to modify phosphogypsum: take phosphogypsum discharged from an enterprise in Guizhou Province as raw material, and its chemical composition (mass fraction) is shown in the following table after testing:

[0034] Composition SO 3 CaOSiO 2 F MgO Al 2 o 3 Fe 2 o 3

[0035] Content 39.46 31.40 4.99 0.2 0.04 0.04 0.21

[0036] Ingredient P 2 o 5 Na 2 OK 2 O TiO 2 MnO loss on ignition Total

[0037] Content 1.18 0.09 0.09 0.07 0.01 21.76 100

[0038] First, clean the phosphogypsum with clean water and dry it, then send it to a tunnel kiln and burn it with civil gas at 1300-1360°C for 25 minutes to remove part of the water and P in the phosphogypsum. 2 o 5 and fluorine, and then grind the calcined charge to 400-450 mesh for later use. At this time, the composition of phosphogypsum has changed, and its chemical composition (mass fraction) is as shown in the following table after testing:

[0039] Composition SO 3 CaOSiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com