Filter medium for removing diethylstilbestrol in water and preparation method thereof

A technology of diethylstilbestrol and filter medium is applied in the field of filter medium for removing diethylstilbestrol in water and its preparation field, and achieves the effects of improving water quality, wide source of raw materials and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

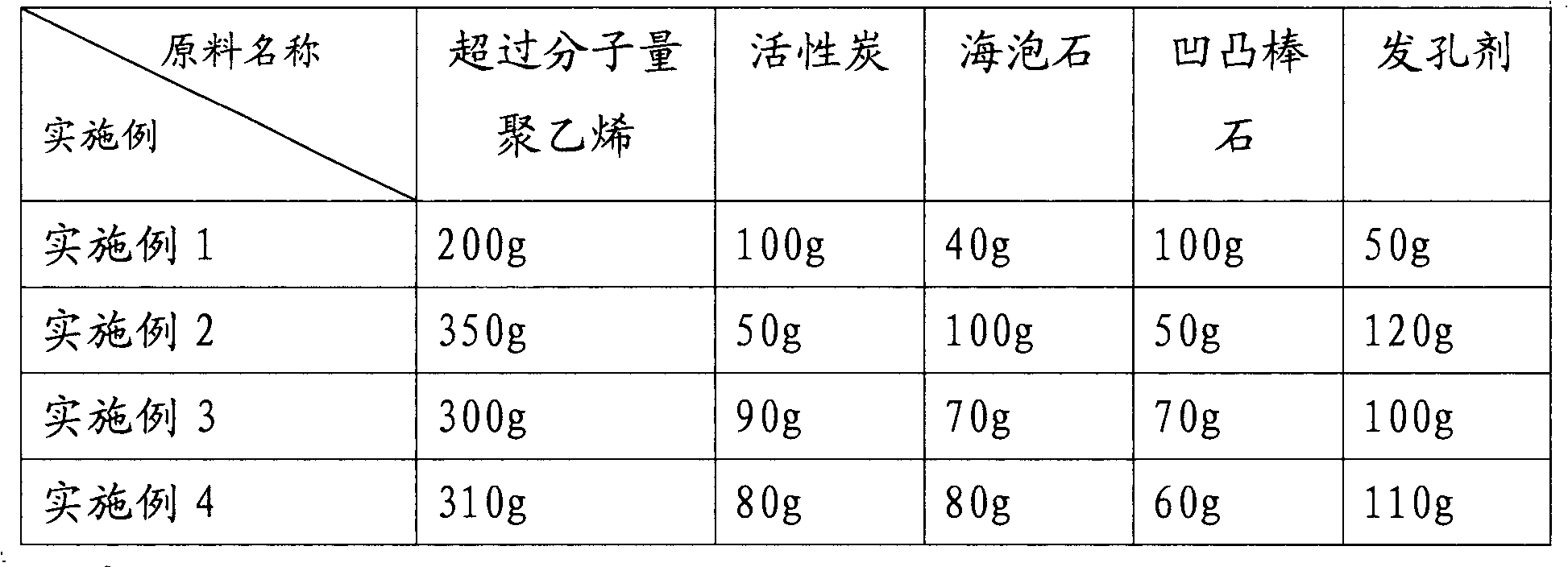

Examples

Embodiment 1

[0030] The specific steps of this embodiment include the following steps:

[0031] (1) Take ultra-high molecular weight polyethylene powder 200g (gram), and described ultra-high molecular weight polyethylene is the M-III type product of Beijing Dongfang Petrochemical Co., Ltd. auxiliary agent two factory, and its molecular weight is 3,500,000, and particle diameter is 74-89 microns;

[0032] (2) Take medical active carbon powder 100g, the particle diameter of described medical active carbon is 74~89 microns;

[0033] (3) take sepiolite powder 40g, described sepiolite powder is obtained through following method: with the sepiolite powder of 74~89 microns, clean with deionized water, dry, soak in the HCl of 0.05 6 Hours, then neutralized with alkali and cleaned with deionized water, dried to get final product;

[0034] (4) Take by weighing modified attapulgite powder 100g, described modified attapulgite powder is obtained through following method processing:

[0035] The atta...

Embodiment 2

[0041] The specific steps of this embodiment include the following steps:

[0042] (1) Weigh 350 g of ultra-high molecular weight polyethylene powder. The ultra-high molecular weight polyethylene is the M-III product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. Micron;

[0043] (2) Take medical activated carbon powder 50g, the particle diameter of described medical activated carbon is 74~89 microns;

[0044] (3) Take sepiolite powder 100g, described sepiolite powder is obtained through following method: with the sepiolite powder of 74~89 microns, clean up with deionized water, dry, soak in the HCl of 0.05 6 Hours, then neutralized with alkali and cleaned with deionized water, dried to get final product;

[0045] (4) Take by weighing modified attapulgite powder 50g, described modified attapulgite powder is obtained through following method processing:

[0046] The attapulgite powder is soaked statically in hydrochloric acid solution with a concentration of 5wt% ...

Embodiment 3

[0052] The specific steps of this embodiment include the following steps:

[0053] (1) Weigh 300 g of ultra-high molecular weight polyethylene powder. The ultra-high molecular weight polyethylene is the M-III product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. Micron;

[0054] (2) Take medical active carbon powder 90g, the particle diameter of described medical active carbon is 74~89 microns;

[0055] (3) Take sepiolite powder 70g, described sepiolite powder is to obtain through following method: with the sepiolite powder of 74~89 microns, clean with deionized water, dry, soak in the HCl of 0.05 6 Hours, then neutralized with alkali and cleaned with deionized water, dried to get final product;

[0056] (4) Take by weighing modified attapulgite powder 70g, described modified attapulgite powder obtains through following method processing:

[0057] The attapulgite powder is soaked statically in hydrochloric acid solution with a concentration of 5wt% (mass fractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com