Method for preparing high-purity danshinolic acid B

A salvianolic acid, high-purity technology, applied in the field of extracting high-purity salvianolic acid B, can solve the problems of not too high salvianolic acid B purity, cumbersome operation process, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

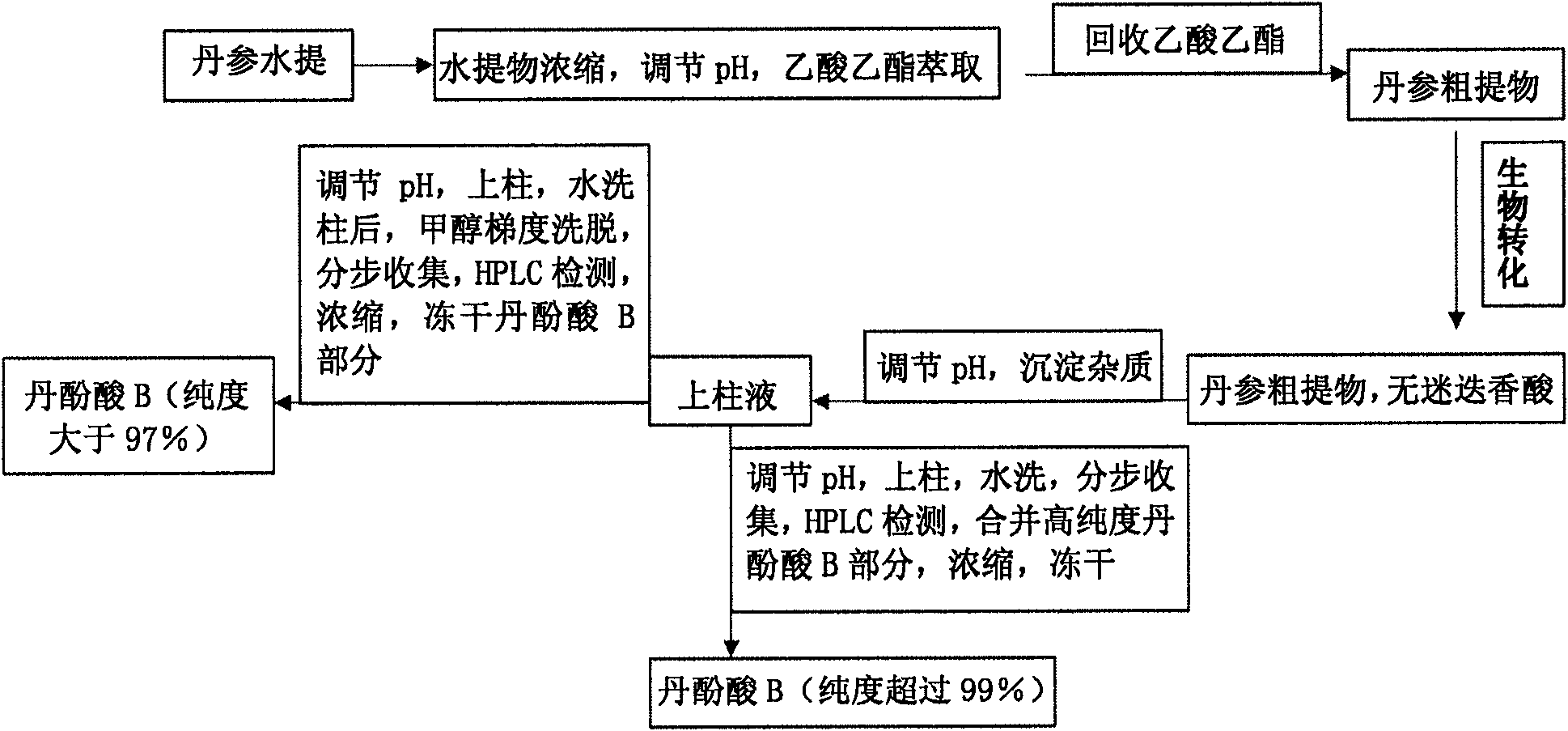

[0045] The preparation method of the high-purity salvianolic acid B provided by the invention comprises steps:

[0046] (1) the water extract of Salvia miltiorrhiza 20-70g and 10 9 -10 10 Individuals / ml of Fusarium graminearum (Fusarium graminearum) resting cells were contacted and placed at 20-35°C for 24-90 hours to obtain an aqueous extract of Salvia miltiorrhiza from which rosmarinic acid was removed; and

[0047] (2) The water extract of Salvia miltiorrhiza from which rosmarinic acid was removed was adsorbed by reversed-phase resin and eluted with water or methanol aqueous solution to obtain high-purity salvianolic acid B.

[0048] Preferably, 40-50g of salvia miltiorrhiza water extract and 5×10 9 -10 10 pcs / ml 10 9 Resting cells are mixed.

[0049] Preferably, air is introduced at 22-32°C, stirred or oscillated for 30-80 hours to obtain the aqueous extract of Danshen from which rosmarinic acid has been removed; more preferably, air is introduced at 25-30°C, stirred ...

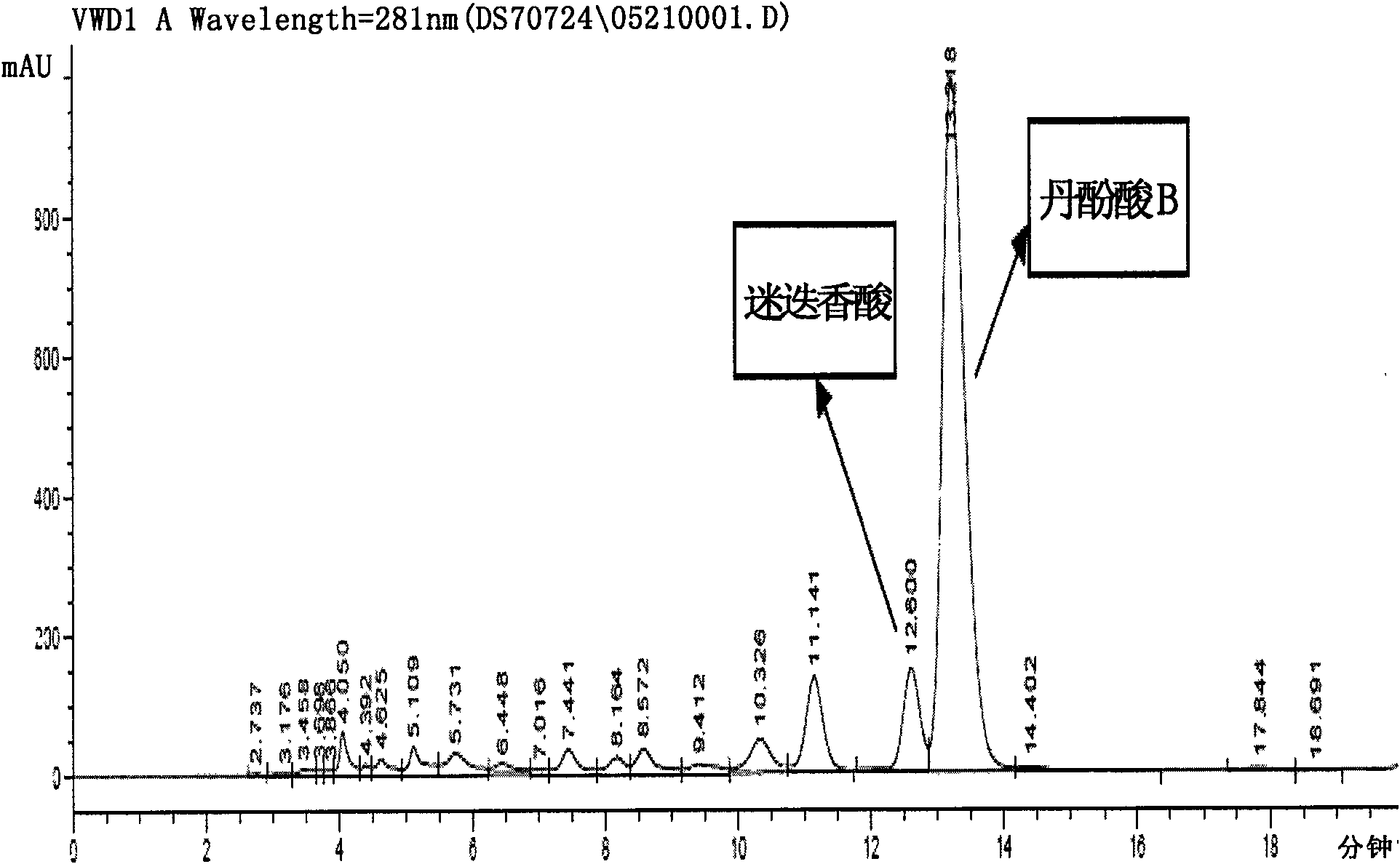

Embodiment 1

[0080] Weigh 100g of dried salvia miltiorrhiza (salvianolic acid B content 2%), add 400ml of water to extract twice at 90°C, combine the two filtrates, concentrate under reduced pressure to 50ml, adjust pH2, add 50ml ethyl acetate to extract twice, combine the two filtrates Ethyl acetate solution was concentrated to recover ethyl acetate. Dissolve the concentrated residue in 200ml of pH7 phosphate buffer, add 10g of wet cells of Fusarium graminearum, shake on a shaker at 28°C, transform for 36 hours, and obtain a crude extract of salvianolic acid without rosmarinic acid . The crude extract was sterilized by filtration, adjusted to pH 2, allowed to stand still to precipitate impurities, filtered and then applied to reversed-phase resin XAD-2, with a resin volume of 200ml. After the column is applied, 1000ml of water is used to elute the resin column, and then 45% methanol is used to elute the resin column until the impurities whose retention time is less than salvianolic acid ...

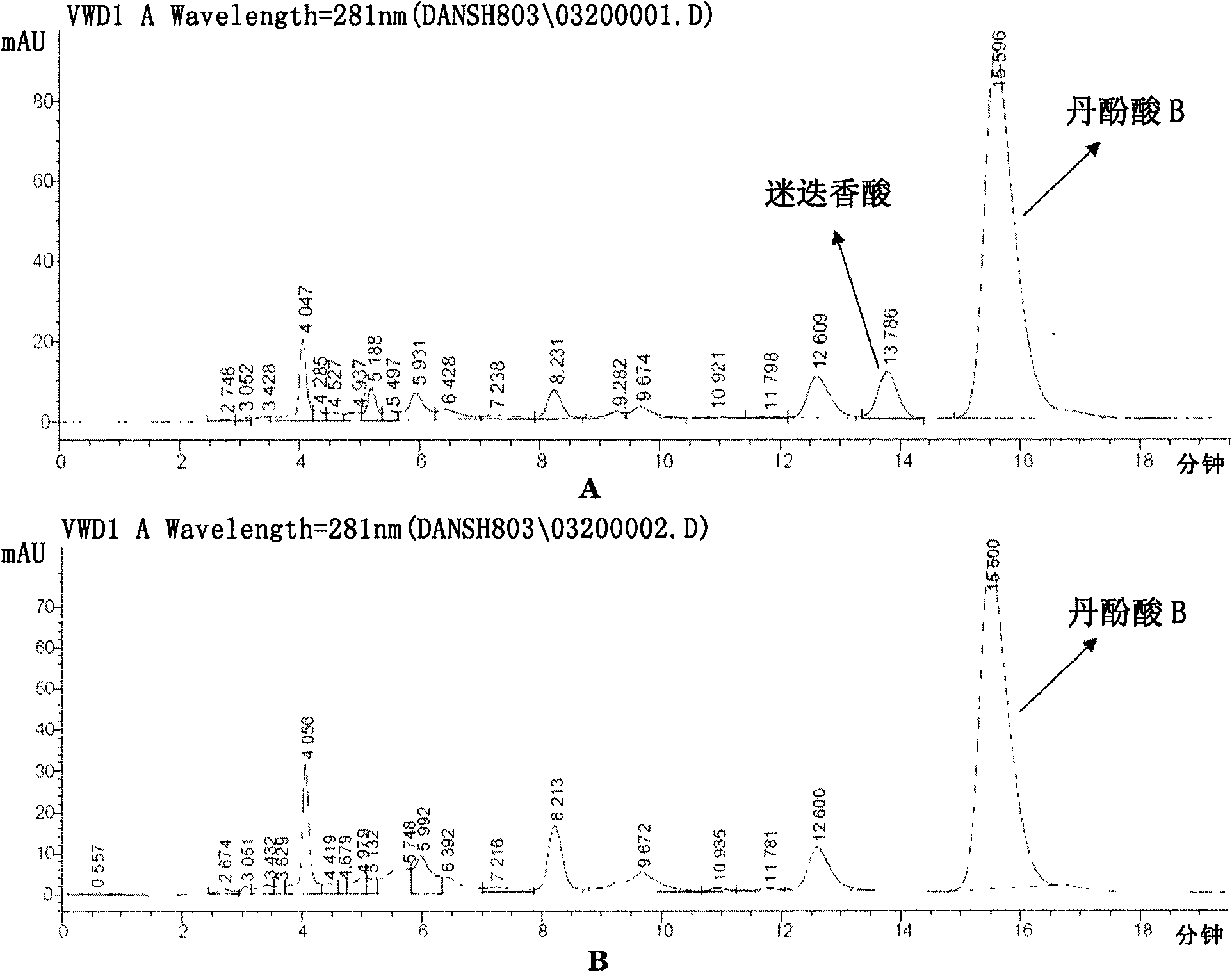

Embodiment 2

[0087]Weigh 100g of dried salvia miltiorrhiza (salvianolic acid B content 2%), add 400ml of water to extract twice at 90°C, combine the two filtrates, concentrate under reduced pressure to 50ml, adjust pH2, add 50ml ethyl acetate to extract twice, combine the two filtrates Ethyl acetate solution was concentrated to recover ethyl acetate. Dissolve the concentrated residue in 200ml of pH7 phosphate buffer, add 10g of wet cells of Fusarium graminearum, shake on a shaker at 28°C, transform for 36 hours, and obtain a crude extract of salvianolic acid without rosmarinic acid . Filter and sterilize the crude extract, then adjust the pH to 2, let stand to precipitate impurities, adjust the filtrate to pH 7 after filtration, apply reverse phase resin HP-20, and wash with water to collect salvianolic acid B eluate with a purity of 99%. , combined, adjusted to pH 2, extracted with ethyl acetate to remove salt, recovered ethyl acetate, dissolved salvianolic acid B in water, and lyophiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com