Method for co-producing hydrogen and methane by utilizing dry anaerobic fermentation of solid organic wastes

A technology of organic waste and dry fermentation, applied in the fields of environmental protection, energy and chemical industry, can solve the problems such as the failure of the flora to play a full role, the incomplete recovery, and the inability to dilute the acid in time, so as to improve energy utilization efficiency and avoid acid cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

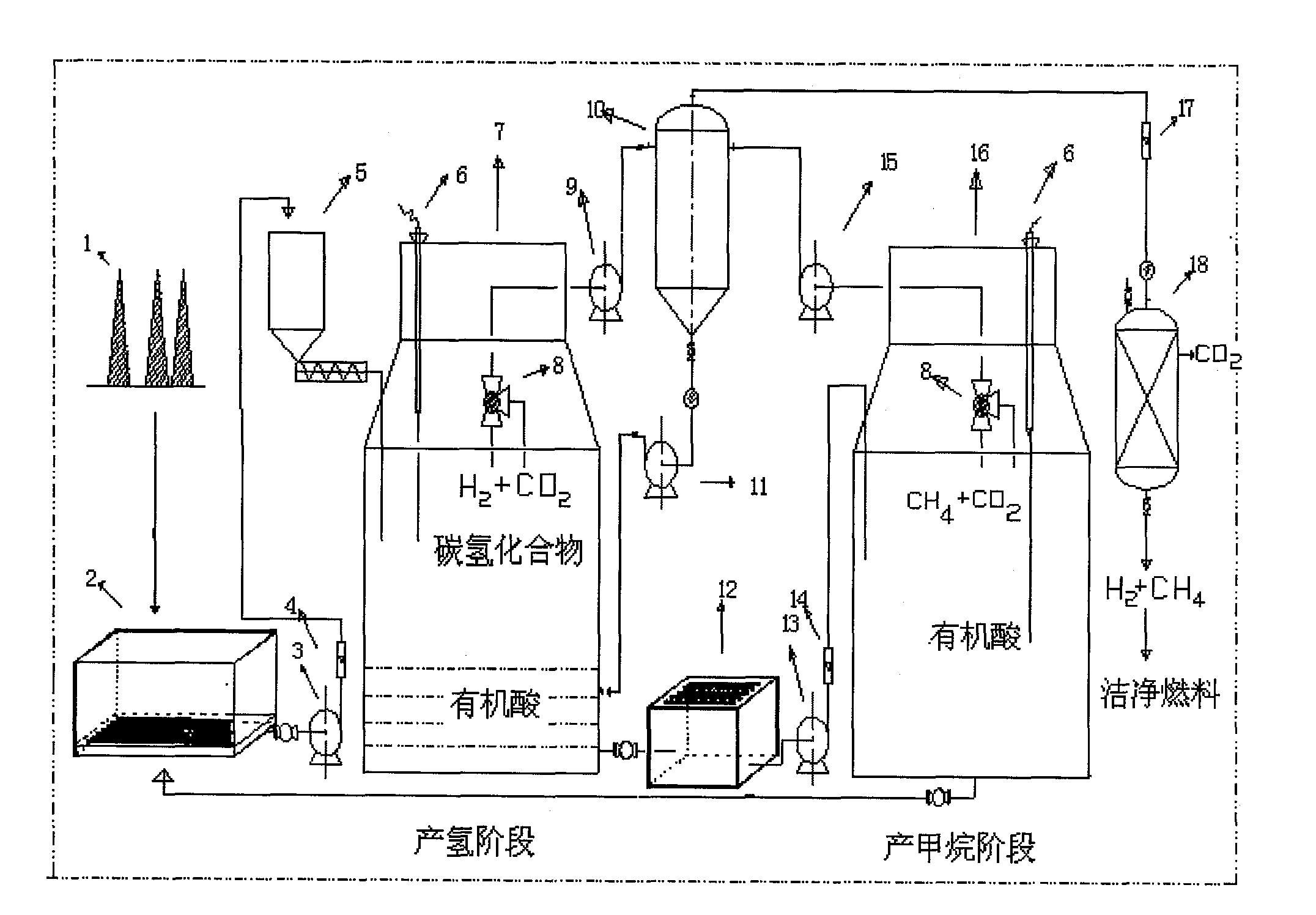

[0026] Below in conjunction with accompanying drawing is embodiment content of the present invention is described further:

[0027] Such as figure 1 Shown: sort the collected urban waste and agricultural organic waste, pre-treat the sorted organic waste at the solid waste storage site 1, sort and rinse the raw materials, and Add 5% bacterial agent, add ammonium bicarbonate according to 1.5% of the raw material weight, mix well, and accumulate aerobically for 3-5 days, when there are white actinomycetes and the raw material becomes soft to the touch. It is mixed with the biogas slurry from the methanogenic reactor 16 in the adjustment pond 2 to form a high-concentration solution of 20%-30%.

[0028] The high-concentration solution is introduced into the hydrogen production reactor 7 through the pump 3, the flow meter 4, and the feeder 5, and the sludge from the urban sewage treatment plant is inoculated into the hydrogen production reactor 7. The amount of inoculated sludge is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com