Reacting chamber and plasma processing system with same

A reaction chamber and chamber technology, applied in the field of microelectronics, can solve the problems affecting the processing/processing results of workpieces, process yield rate, pumping speed, affecting workpiece processing/processing results, and affecting process yields, etc., to avoid Airflow reflection and turbulence, reduced pumping time, effect of reduced pumping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the reaction chamber and the plasma processing system provided with the reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

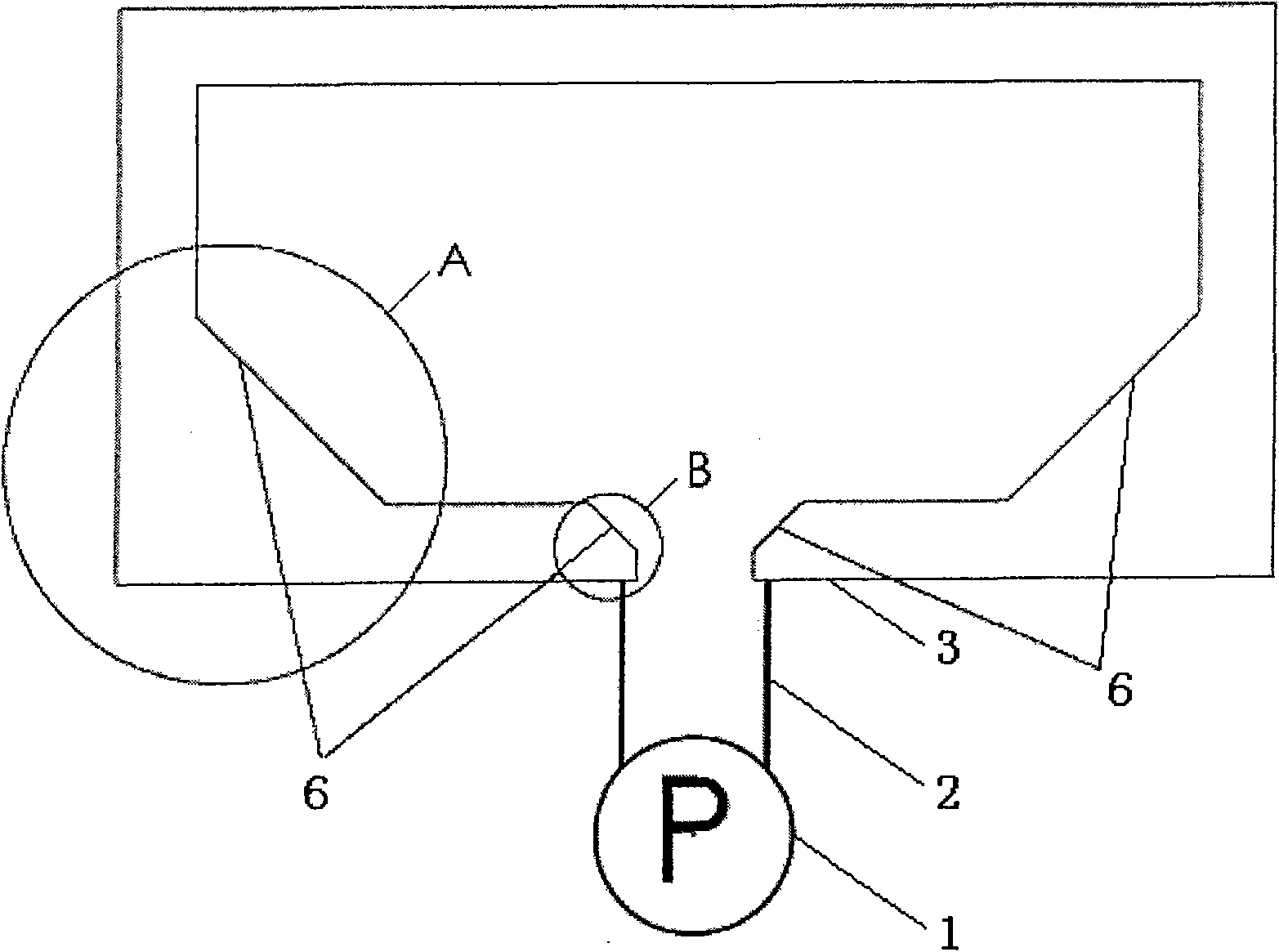

[0030] see image 3 , which shows the reaction chamber provided by the first embodiment of the present invention. Let’s take the left half of the chamber 3 as an example for illustration. The positions of the inner walls A and B of the chamber are designed as inclined plane structures 6. The inclined plane structures 6 follow the flow direction of the air flow and are located at the corners of the chamber. The bevel structure 6 is used at the inward corner position shown by the symbol B, and the bevel structure 6 is also used at the outward corner position shown by the symbol B.

[0031] In this embodiment, the slope angle is approximately 45 degrees, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com