Dry etching method for two-color HgCdTe device and etching device thereof

An etching device and dry etching technology, applied in semiconductor devices, electrical components, sustainable manufacturing/processing, etc., can solve problems such as high damage, improve yield, reduce surface leakage current, and reduce dry etching The effect of erosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0030] The invention is mainly used in the two-color mercury cadmium telluride device process, and solves the problem of high damage to the material surface caused by the deep mesa forming process. By adopting a new type of etching technology and specially developed process conditions for low damage and high rate etching, plus a series of wet chemical etching and heat treatment processes after etching, the two-color HgCdTe device can be well reduced and eliminated. Damage to the countertop molding process.

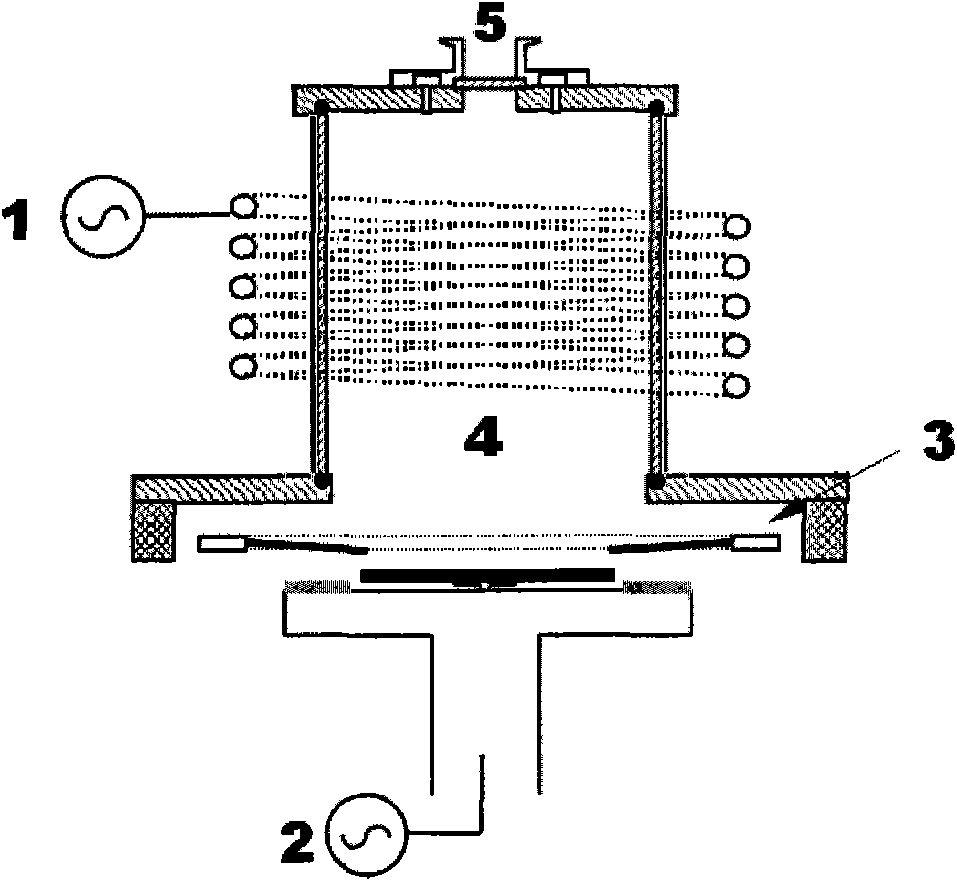

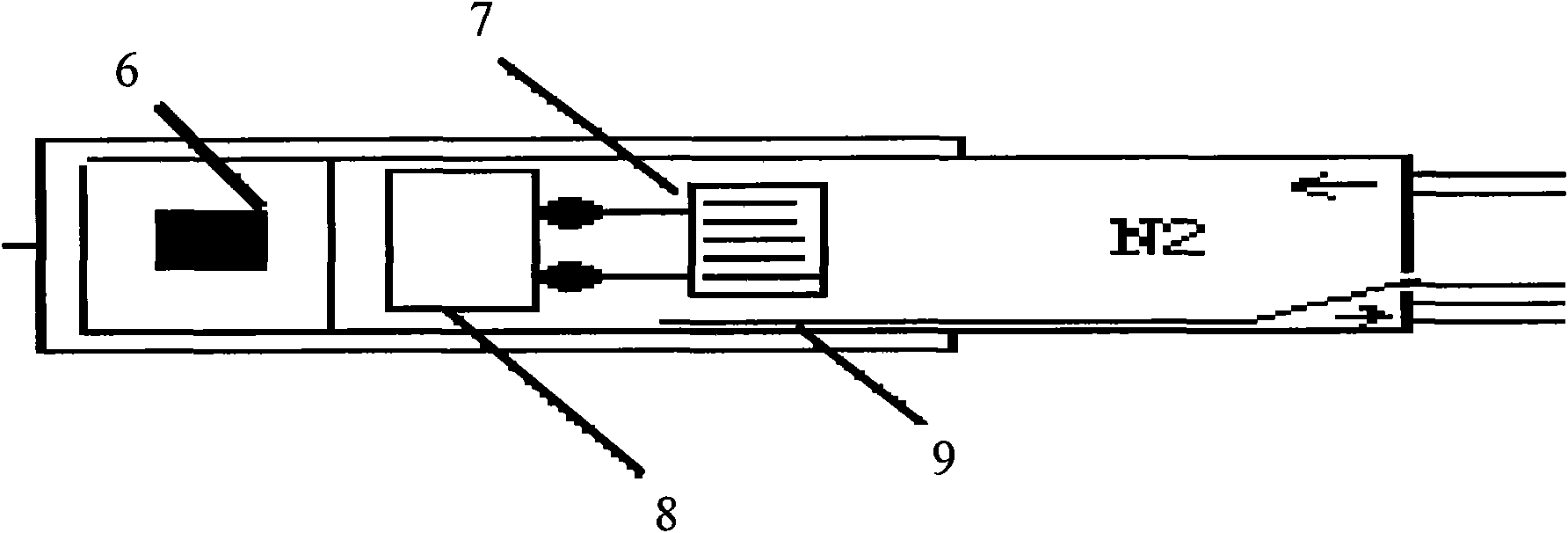

[0031] The present invention reduces etching damage to the greatest extent by adopting a novel ICP (Inductive Coupled Plasma, inductively coupled plasma etching) dry etching device, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com