Method for producing optical film, optical film, polarizing plate and display

A technology of optical film and film method, which is applied in the direction of optics, optical elements, polarizing elements, etc., can solve the problems of peeling deterioration, low production speed, and reduced production speed, so as to reduce the constraints of film production conditions and reduce the delay value. Average, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0300] (atmospheric pressure plasma treatment)

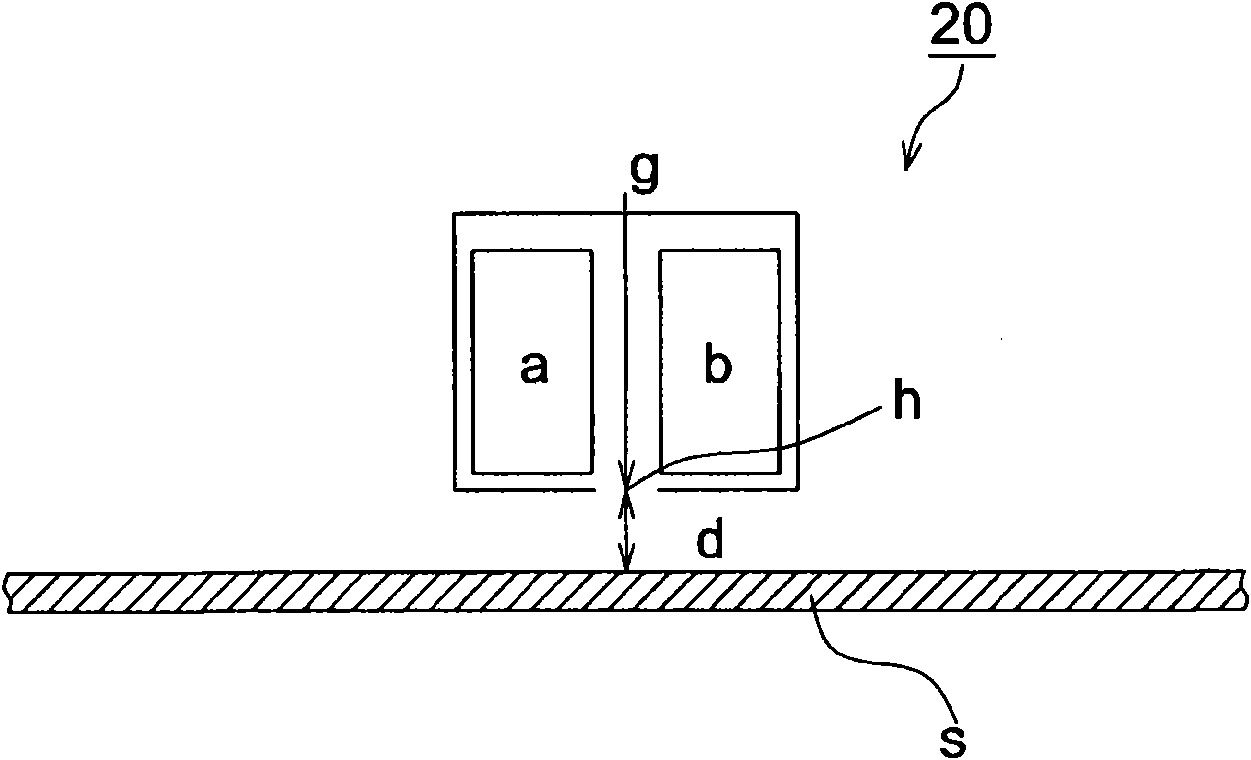

[0301] The gap (d) between the ejection slit (h) of the atmospheric pressure plasma device (20) and the surface of the metal support (s) is set to 2 mm. Under this condition, the metal support (s) is transported while the metal support (s) A plasma irradiation process is performed for 0.0005 seconds by passing under the atmospheric pressure plasma device (20). Since the exact contact time between the free radical and the metal support (s) is difficult to measure, the plasma irradiation time referred to here refers to the time from a certain point on the surface of the metal support (s) from the spray slit (h) Time for the bottom to move across the opening width of the slit (h). For example, if the opening width of the ejection slit (h) is 2 mm and the moving speed of the metal support (s) is 2 mm / sec, the plasma irradiation time is 1 sec. In addition, the amount of reaction gas (g) used is 3m per 1m of irradiation width 3 / mi...

Embodiment 2

[0304] The only difference from Example 1 is that the plasma irradiation treatment time is 0.01 second, and the solvent vapor concentration near the surface of the plasma (s) before entering the atmospheric pressure plasma device (20) is methylene chloride 6500ppm, methanol 1500ppm, others are identical with embodiment 1.

Embodiment 3

[0306] The difference from Example 2 is that 1% by volume of oxygen is added to the reaction gas (g), and the others are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com