Microwave liquid phase compounding process of high-purity barium titanate powder

A pure barium titanate, liquid phase synthesis technology, applied in the preparation of barium titanate powder, microwave liquid phase synthesis, can solve the problem of affecting the performance of barium titanate powder, high Na+ content of barium titanate powder, powder Problems such as washing and purification difficulties, to achieve the effects of short reaction time, high product purity and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 113.68 g of analytically pure tetraisopropyl titanate, and with rapid stirring, hydrolyze it in a beaker filled with 2 L of pure water. After stirring for 10 min, the hydrolyzate is filtered and washed. The hydrolyzate was redispersed and diluted to a volume of 600 ml with pure water in a beaker, 19 g of analytically pure nitric acid with a concentration of 65% was added, and water was replenished to a volume of 1 L. Then, with rapid stirring, the above slurry was heated up and kept at 65° C. for 50 minutes to obtain a transparent sol.

[0029] (2) Add 400ml of pure water to a microwave reactor with a capacity of 2.5L, heat it to 85°C by microwave, weigh 257g of barium hydroxide octahydrate (purity > 98wt%) and add it to the kettle, and start stirring to assist the dissolution of barium hydroxide , and add water to a volume of 1L, and prepare a nearly transparent barium hydroxide solution.

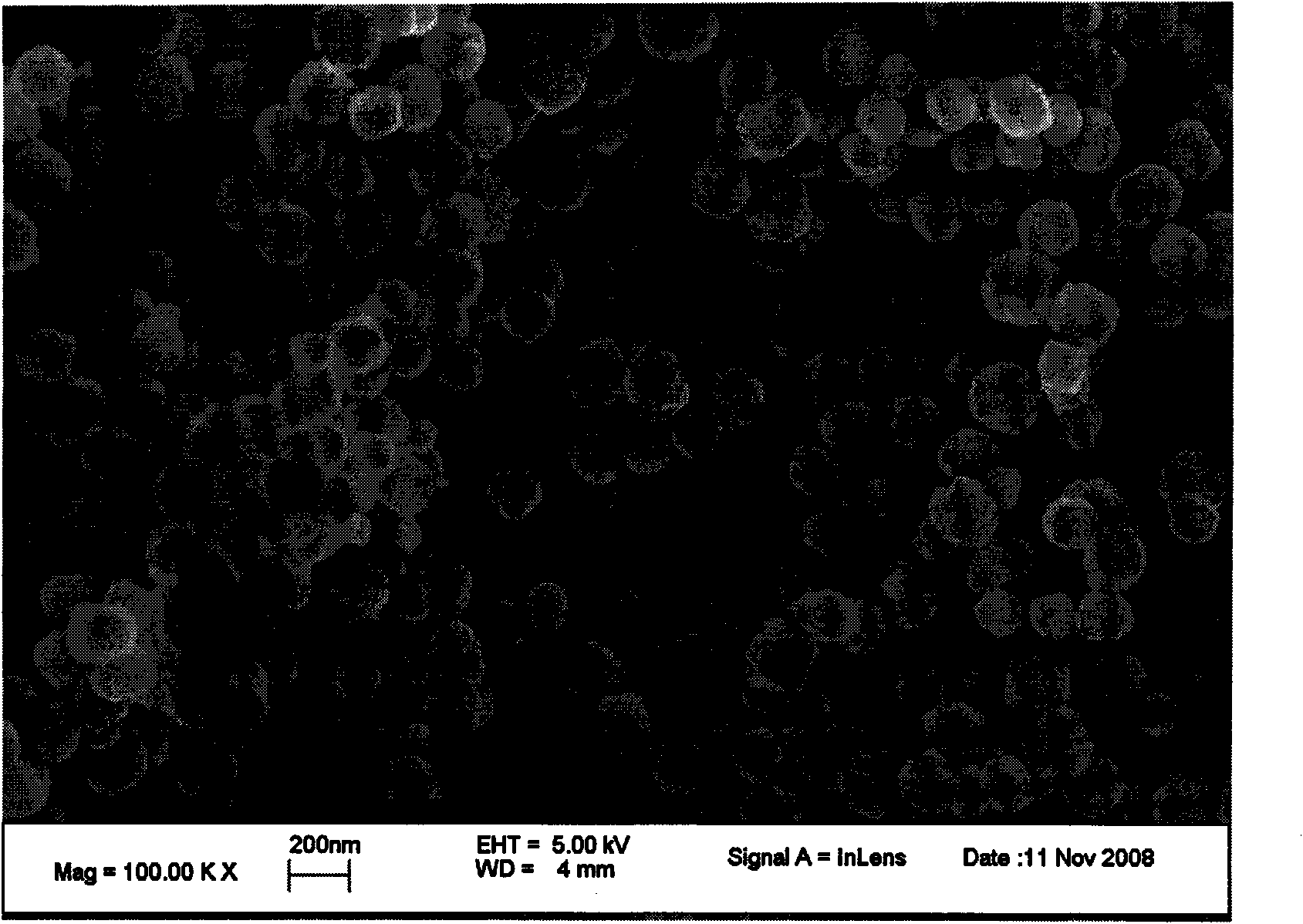

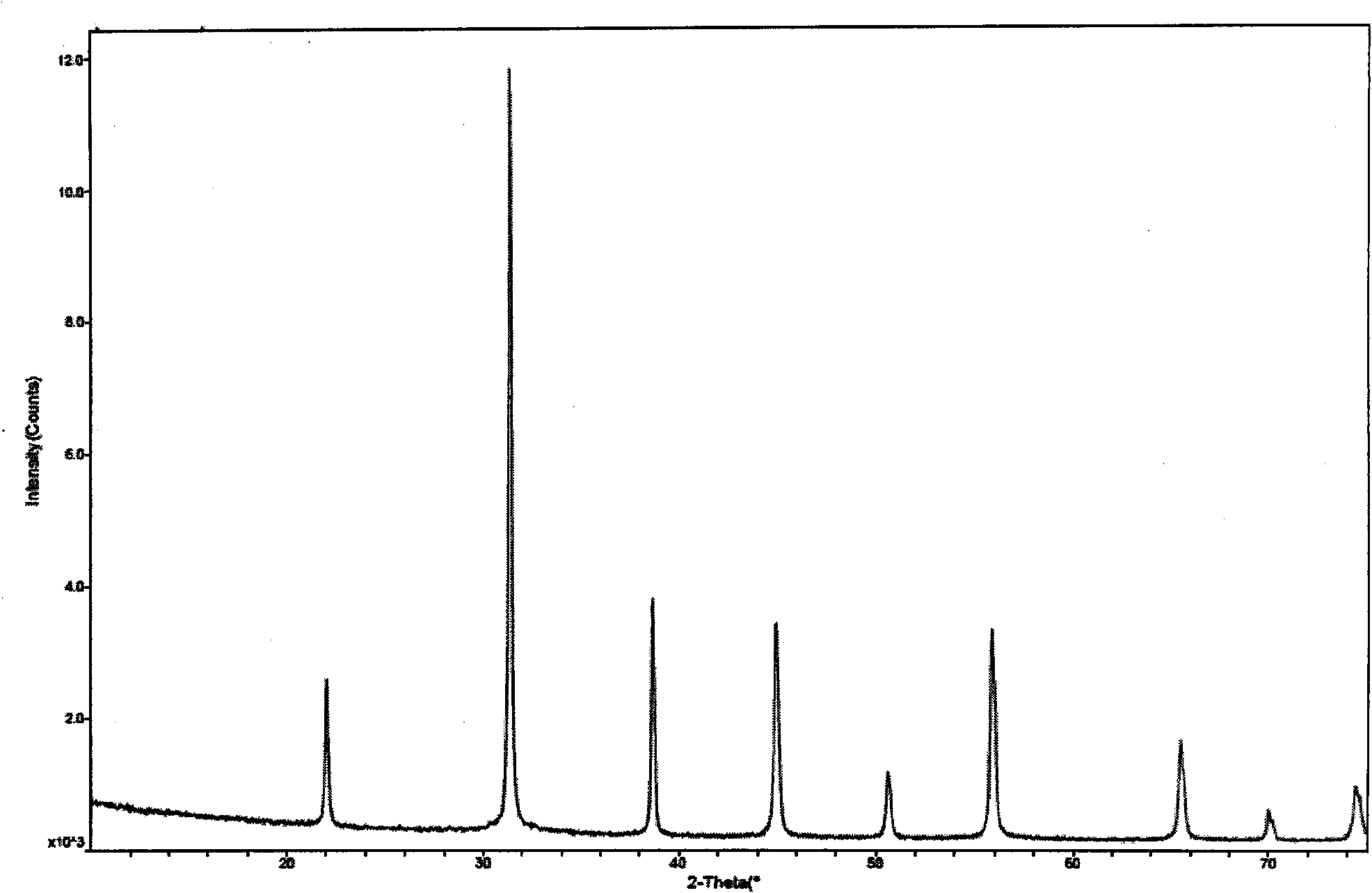

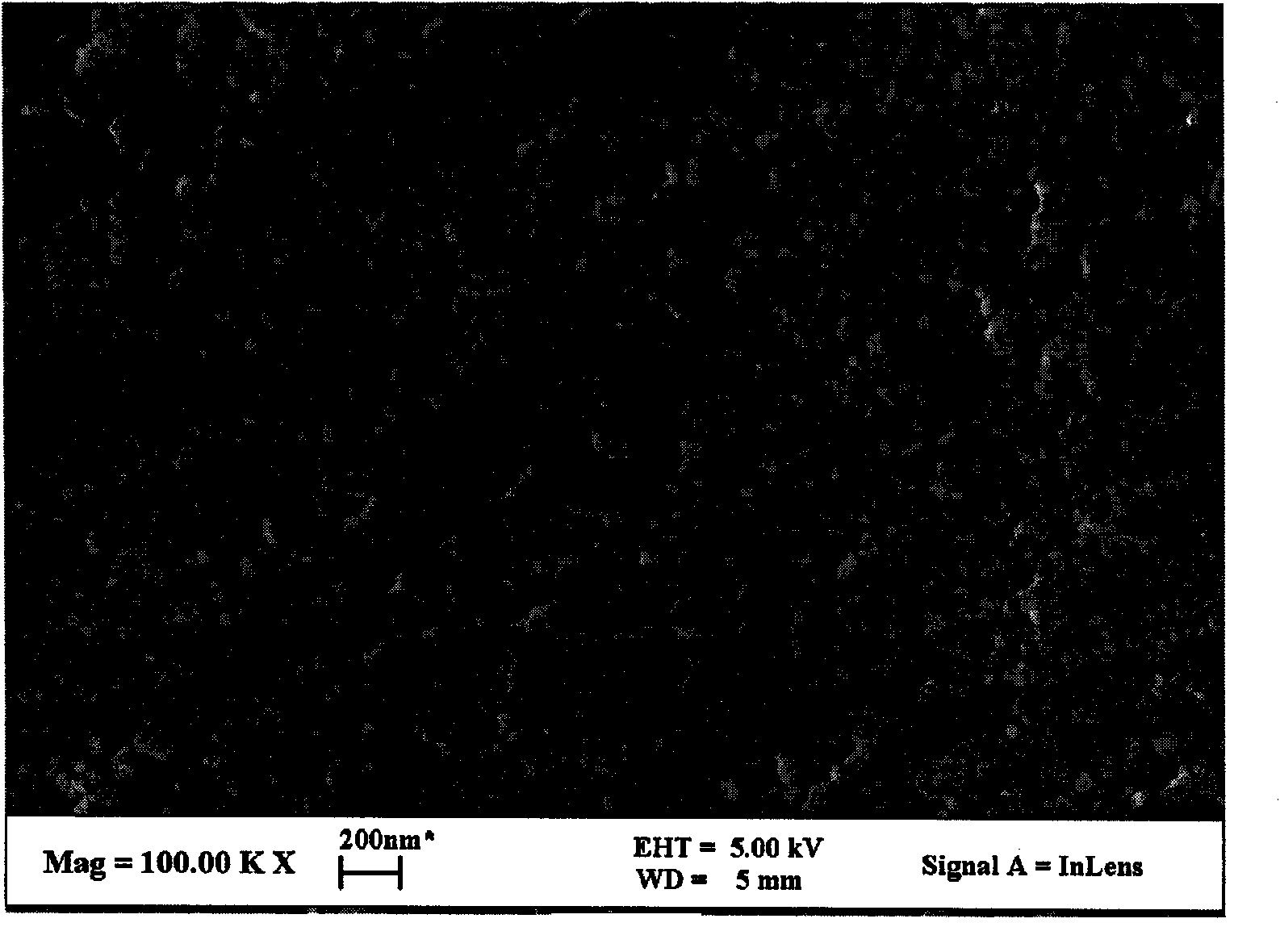

[0030] (3) Under the condition of stirring, the transparent sol obta...

Embodiment 2

[0033] (1) Weigh 284 g of analytically pure tetraisopropyl titanate, and with rapid stirring, hydrolyze it in a beaker filled with 5 L of pure water. After stirring for 10 min, the hydrolyzate is suction-filtered and washed. The hydrolyzate was redispersed and diluted to a volume of 900 ml with pure water in a beaker, 47 g of analytically pure nitric acid with a concentration of 65% was added, and water was replenished to a volume of 1 L. Then with rapid stirring, the above slurry was heated up and kept at 65° C. for 3 hours to obtain a transparent sol.

[0034] (2) Add 700ml of pure water to a microwave reactor with a capacity of 2.5L, heat it to 85°C by microwave, weigh 643g of barium hydroxide octahydrate (purity > 98wt%) and add it to the kettle, and start stirring to assist the dissolution of barium hydroxide , and add water to a volume of 1L, and prepare a nearly transparent barium hydroxide solution.

[0035] (3) Under the condition of stirring, the transparent sol obt...

Embodiment 3

[0038] (1) Weigh 454 g of analytically pure tetraisopropyl titanate, and with rapid stirring, hydrolyze it in a reaction tank filled with 10 L of pure water. After stirring for 10 min, the hydrolyzate is suction-filtered and washed. The hydrolyzate was redispersed and diluted to a volume of 1 L with pure water in a beaker, 76 g of analytically pure nitric acid with a concentration of 65% was added, and water was replenished to a volume of 1.1 L. Then with rapid stirring, the above slurry was heated up and kept at 65° C. for 3 hours to obtain a transparent sol.

[0039] (2) Add 1L of pure water to a microwave reactor with a capacity of 2.5L, heat it to 85°C by microwave, weigh 1029g of octahydrate barium hydroxide (purity > 98wt%) and add it to the kettle, and turn on the stirring auxiliary barium hydroxide Dissolve it, add water to a volume of 1.1L, and prepare a nearly transparent barium hydroxide solution.

[0040] (3) Under the condition of stirring, the transparent sol ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com