High-strength aluminium alloy plate and production method thereof

An aluminum alloy sheet and production method technology, applied in metal rolling, quenching agent, heat treatment equipment and other directions, can solve the problems of unsatisfactory quality of aluminum alloy sheet, uneven heating of materials, long material time, etc., to achieve rapidity and Continuity, conducive to popularization and application, good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. A high-strength aluminum alloy plate and its production method

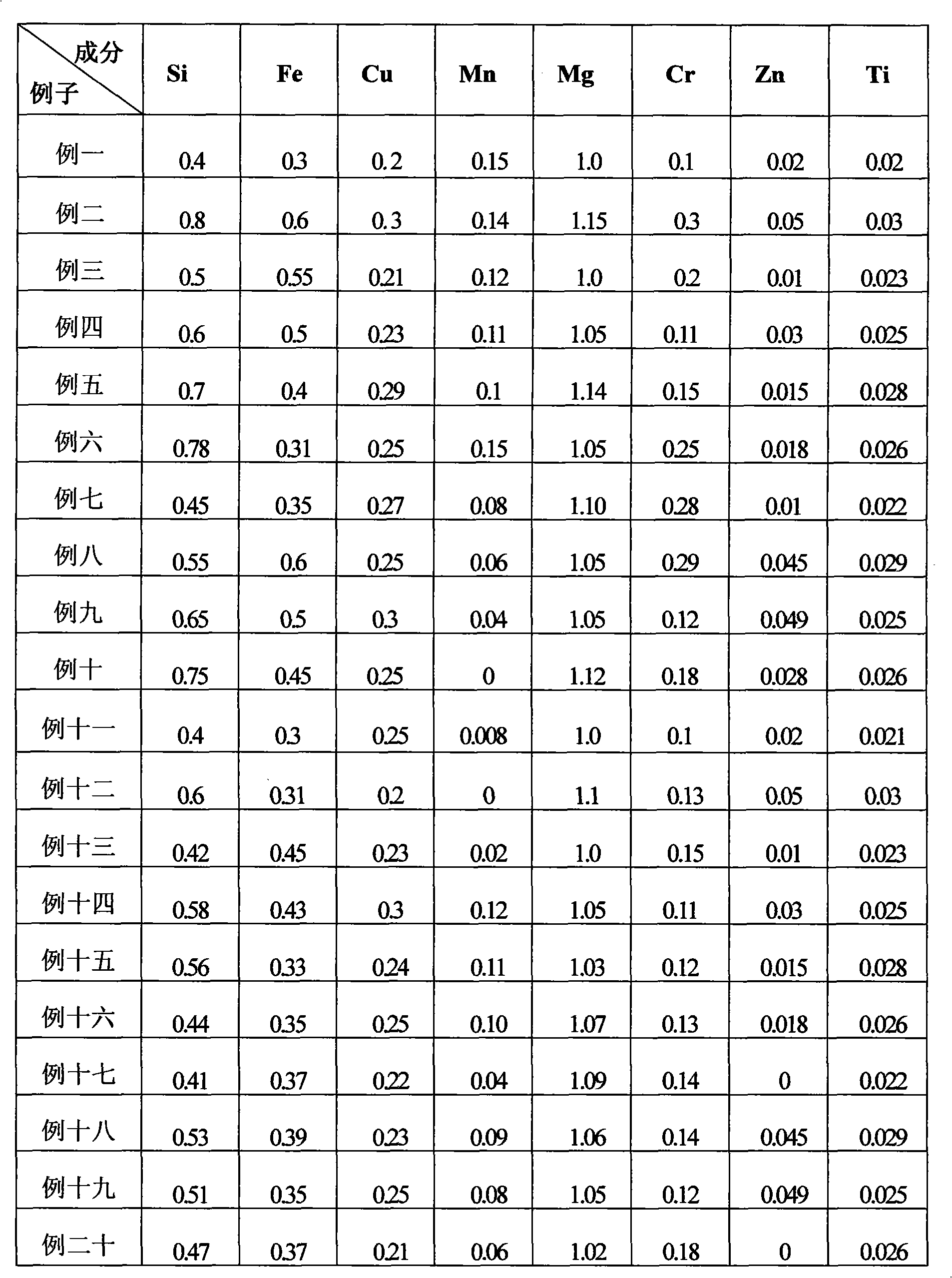

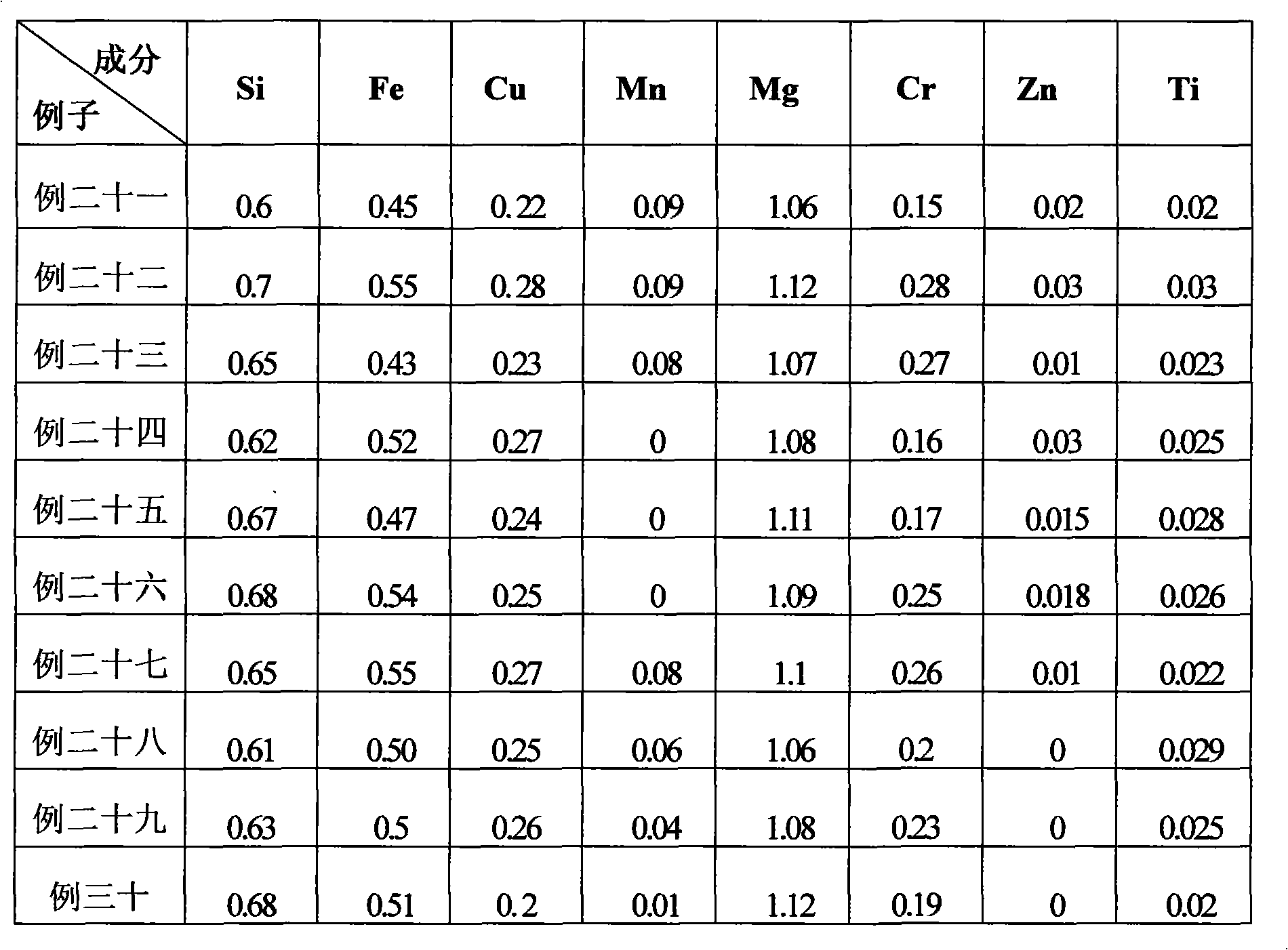

[0031] 1. The alloy composition of the high-strength aluminum alloy plate is shown in Table 1. The values in the table are expressed in parts by weight. The content of other unavoidable impurities is controlled below 0.01 part, and the balance is aluminum. The total of each component is 100 parts.

[0032] 2. Production steps:

[0033] (1) Melting Put the aluminum ingots for remelting and the Al-Si master alloy together into the melting furnace, melt at 700-750°C for 5-8 hours, stir evenly after melting, add Fe, Cr, Cu metal additives and The magnesium ingots are fully stirred evenly, and samples are taken for spectral analysis to see whether the various components except Ti meet the requirements, and then the contents of Si, Fe, Cu, Mg, and Cr are appropriately adjusted to obtain an aluminum alloy melt whose components meet the requirements;

[0034] (2) Refining and standing still The al...

Embodiment 2

[0045] Embodiment 2, high-strength aluminum alloy plate and production method thereof

[0046] 1. The composition of each alloy is shown in Table 1;

[0047] 2. production method is basically the same with embodiment one, and difference is process parameter:

[0048] (1) Melting Put the aluminum ingot for remelting and the Al-Si master alloy into the melting furnace, and melt at 700°C for 8 hours;

[0049] (2) Refining and standing still Refining the aluminum alloy melt at 720°C for no less than 20 minutes, removing scum, and then standing for 40 minutes; The nitrogen volume in the chlorine mixture accounts for 90% of the total volume;

[0050] (3) Continuously add aluminum titanium boron wire on the casting line to make the content of titanium components meet the requirements; remove hydrogen online, and after hydrogen removal, the hydrogen content in the aluminum melt is below 0.15ml / 100gAl, and then at a temperature of 700°C and a speed of 40mm / The aluminum alloy ingot ...

Embodiment 3

[0057] Embodiment 3, high-strength aluminum alloy plate and its production method

[0058] 1. The composition of each alloy is shown in Table 1;

[0059] 2. production method is basically the same with embodiment one, and difference is process parameter:

[0060] (1) Melting Put the aluminum ingot for remelting and the Al-Si master alloy into the melting furnace, and melt at 750°C for 5 hours;

[0061] (2) Refining and standing still Refining the aluminum alloy melt at 740°C for no less than 20 minutes, removing scum, and then standing for 40 minutes; The nitrogen volume in the chlorine mixture accounts for 88% of the total volume;

[0062] (3) Continuously add aluminum-titanium-boron wire on the casting line to make the content of titanium components meet the requirements; dehydrogenation on-line, after dehydrogenation, the hydrogen content in the aluminum melt is below 0.15ml / 100gAl, and then at a temperature of 710°C and a speed of 45mm / The aluminum alloy ingot was cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com