Preparation method of ZnS/ZnSe composite infrared transmission material

An infrared transmission, zinc selenide technology, applied in the field of chemical vapor deposition CVD, can solve the problems of increasing process difficulty and risk, strict exhaust gas treatment, increasing production cost, etc., achieving good application prospects, low price, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

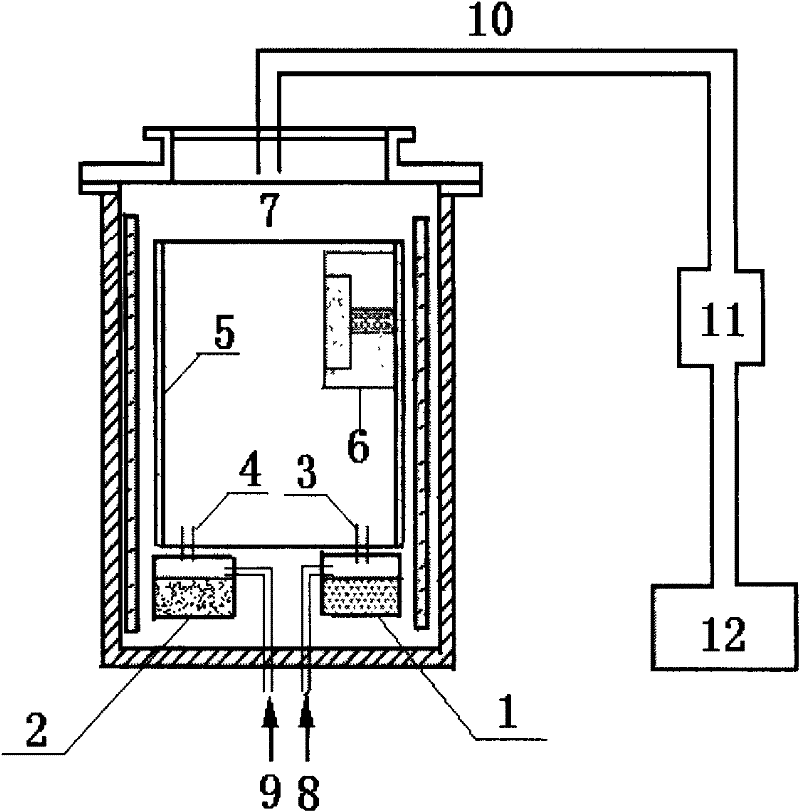

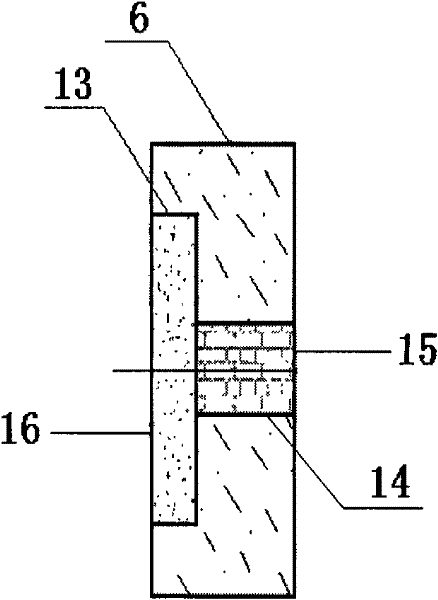

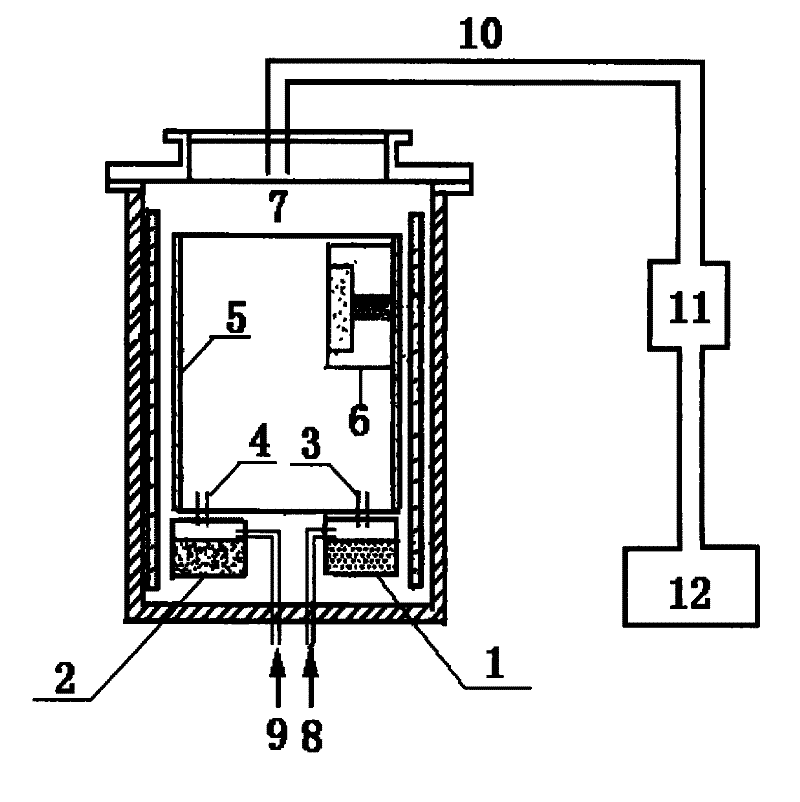

Method used

Image

Examples

Embodiment 1

[0026] Polish a φ40mm×5mm ZnSe substrate. The polished substrate is ultrasonically treated with alcohol for 15 minutes, dried with cotton wool, placed in a muffle furnace, and kept at 200°C for 12 hours; then plasma cleaning is performed to obtain a clean and active ZnSe substrate. surface, to ensure the bonding force between the two layers; put the plasma-cleaned ZnSe substrate into the growth mold, and then put it into the upper half of the deposition chamber at a certain position; put the zinc and sulfur raw materials into their respective crucibles, Cover the sealing cover of the deposition furnace, start the vacuum system, pump out the air in the furnace, then raise the temperature of the deposition chamber to 560°C, raise the temperature of the zinc crucible to 500°C, and raise the temperature of the sulfur crucible after the zinc crucible starts to heat up for 2 hours to 300°C; the flow rate of argon gas in the zinc crucible: the flow rate of argon gas in the sulfur cruc...

Embodiment 2

[0028] Other conditions and operations are the same as in Example 1, only the temperature and pressure of the deposition chamber and the deposition time are changed: the temperature of the deposition chamber is controlled at 600°C, the pressure of the entire system is controlled at 520±20Pa, the temperature of the deposition chamber is kept constant during the growth process, and the deposition The zone temperature is controlled at 600°C, and the entire deposition process lasts for 50 hours from the gas feeding. The overall thickness of the ZnS / ZnSe composite material was measured to be 6.30 mm, and the thickness of the ZnS deposition layer was 1.30 mm.

Embodiment 3

[0030] Other conditions and operations are the same as Case 1. Only change the temperature and pressure of the deposition chamber and the deposition time:

[0031] The temperature of the deposition chamber is controlled at 700°C, the pressure of the entire system is controlled at 700±20Pa, the temperature of the deposition chamber is kept constant during the growth process, the temperature of the deposition area is controlled at 690°C, and the entire deposition process lasts for 50 hours from the start of gas injection. The overall thickness of the ZnS / ZnSe composite was measured to be 6.40 mm, and the thickness of the ZnS deposition layer was 1.40 mm.

[0032] To sum up, the key issues in the preparation of ZnS / ZnSe composites by zinc and sulfur solid-phase elemental reaction mode chemical vapor deposition are how to prepare ZnS / ZnSe composites with a good interface between the two phases, and how to prepare the composites completely from the growth How to eliminate the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com