Preparation method of Al2O3/TiO2 compound dielectric film aluminum electrode foil

A technology of composite dielectric film and aluminum electrode foil, which is applied in the direction of capacitor electrodes, circuits, capacitors, etc., can solve the problems of long cycle time and easy burning of aluminum electrode foil, so as to reduce industrial production energy consumption, high anodic oxidation current utilization efficiency, The effect of increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

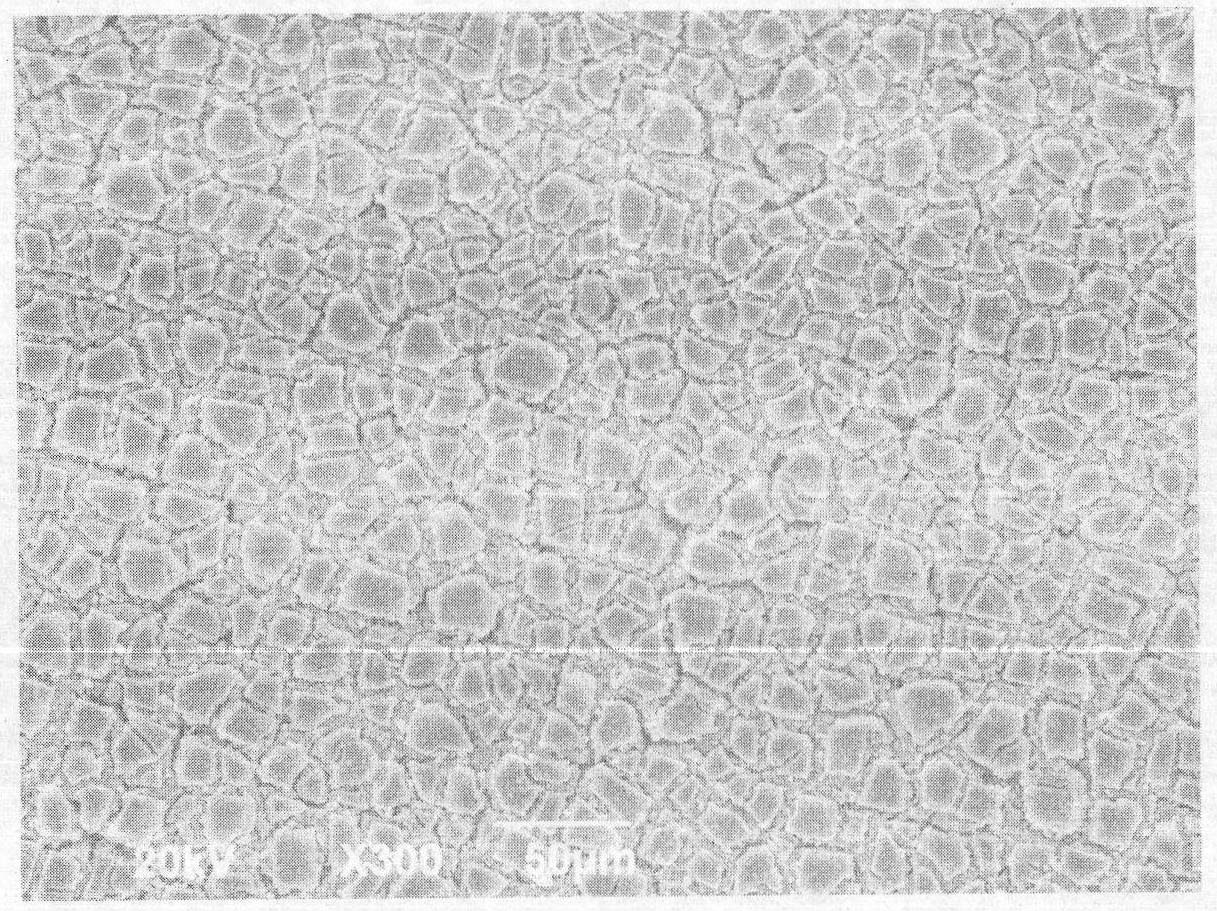

[0039] Mix deionized water and methanol uniformly at a ratio of 3:1 to obtain methanol aqueous solution, add TiCl 4 and H 2 o 2 solution, control TiCl 4 Concentration is 0.005mol / L, H 2 o 2 The concentration is 0.02mol / L, and the temperature of the solution is controlled at 5°C; then, the inert metal platinum is used as the positive electrode, and the aluminum corrosion foil is subjected to cathodic electrodeposition, the current is 0.005A, the voltage is 8V, and the deposition time is 20 minutes.

[0040] Through low temperature and high temperature heat treatment, the temperature of low temperature heat treatment is 75°C, and the treatment time is 5 minutes; the temperature of high temperature heat treatment is 550°C, and the treatment time is 10 minutes. Anatase-type TiO was deposited on the surface of aluminum corrosion foil through the above-mentioned temperature-controlled heat treatment. 2 Nano oxide film.

[0041] After using the above-mentioned process, the corr...

Embodiment approach 2

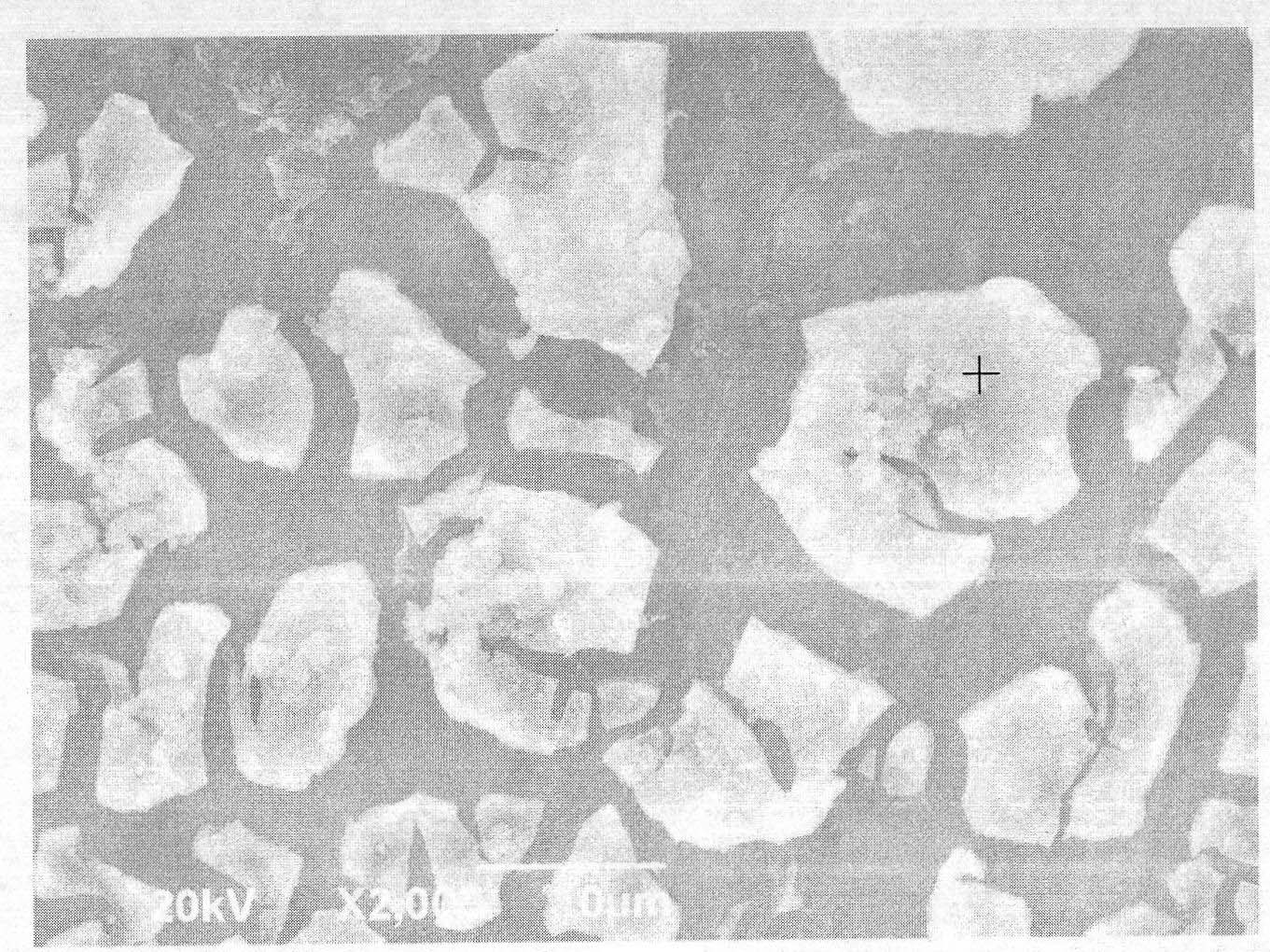

[0043] Mix deionized water and methanol uniformly at a ratio of 3:1 to obtain methanol aqueous solution, add TiCl 4 and H 2 o 2 solution, control TiCl 4 Concentration is 0.01mol / L, H 2 o 2 The concentration is 0.03mol / L, and the temperature of the solution is controlled at 5°C; then, the inert metal platinum is used as the positive electrode, and the aluminum corrosion foil is subjected to cathodic electrodeposition, the current is 0.01A, the voltage is 15V, and the deposition time is 10 minutes.

[0044] Through low temperature and high temperature heat treatment, wherein the temperature of low temperature heat treatment is 60°C, and the treatment time is 5 minutes; the temperature of high temperature heat treatment is 450°C, and the treatment time is 10 minutes. Anatase-type TiO was deposited on the surface of aluminum corrosion foil through the above-mentioned temperature-controlled heat treatment. 2 Nano oxide film.

[0045] After using the above-mentioned process, t...

Embodiment approach 3

[0047] Mix deionized water and methanol uniformly at a ratio of 3:1 to obtain methanol aqueous solution, add TiCl 4 and H 2 o 2 solution, control TiCl 4 Concentration is 0.1mol / L, H 2 o 2 The concentration is 0.2mol / L, and the temperature of the solution is controlled at 20°C; then, the inert metal platinum is used as the positive electrode, and the aluminum corrosion foil is subjected to cathodic electrodeposition, the current is 0.5A, the voltage is 50V, and the deposition time is 1 minute.

[0048] Through low temperature and high temperature heat treatment, the temperature of low temperature heat treatment is 100°C, and the treatment time is 5 minutes; the temperature of high temperature heat treatment is 600°C, and the treatment time is 2 minutes. Anatase-type TiO was deposited on the surface of aluminum corrosion foil through the above-mentioned temperature-controlled heat treatment. 2 Nano oxide film.

[0049] After using the above-mentioned process, the corroded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com