Synthesis method of tourmaline

A synthesis method and tourmaline technology, applied in silicate, aluminum silicate and other directions, can solve the problems of high equipment requirements, high preparation cost, wide product particle size distribution, etc., and achieve easy operation, mild conditions, and equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

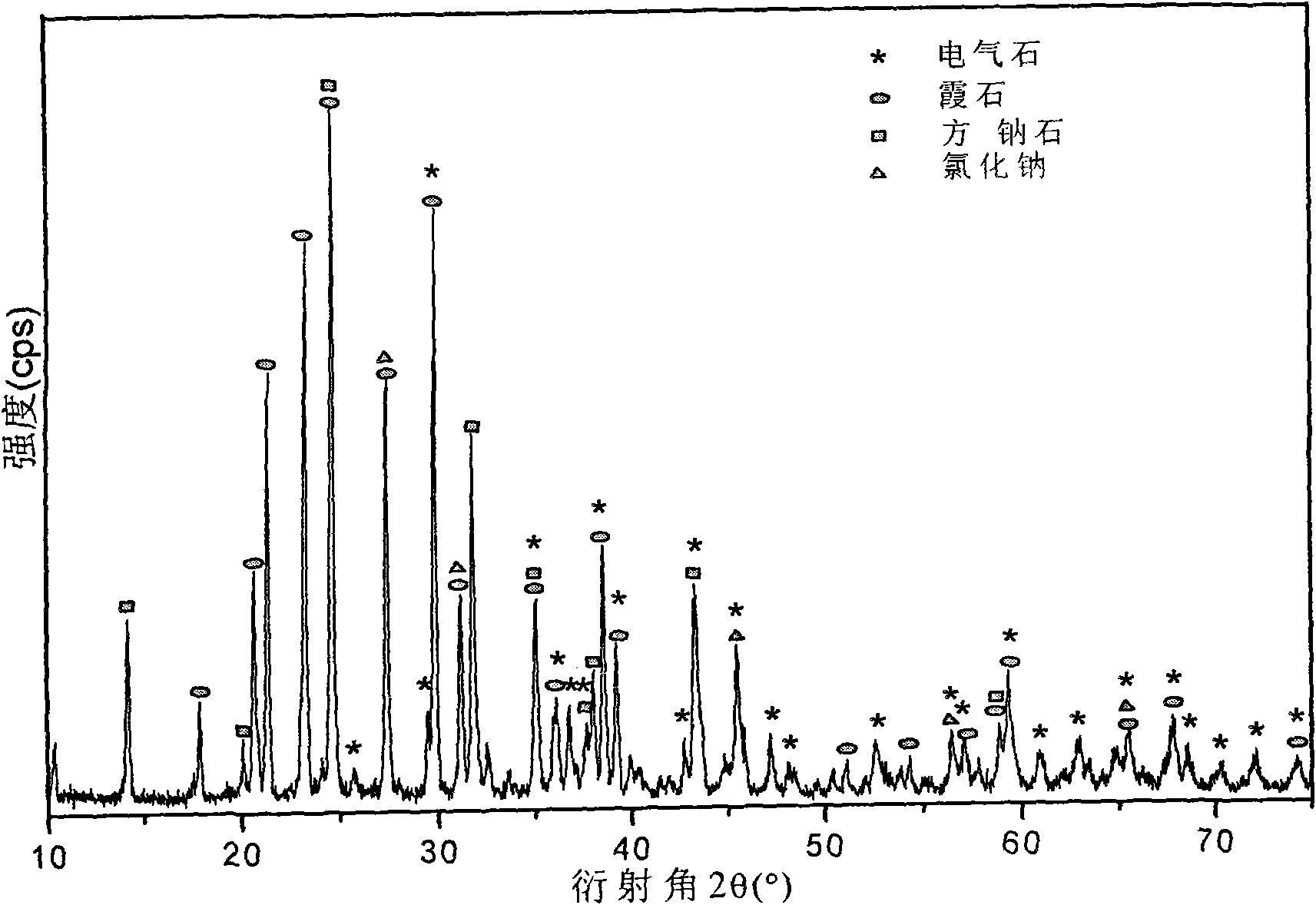

Image

Examples

Embodiment 1

[0024] (1) Weighing of reactants and preparation of solutions. Weigh magnesium chloride (MgCl 2 ·6H 2 O), aluminum chloride (AlCl 3 ), sodium silicate (Na 2 SiO 3 9H 2 O), boric acid (H 3 BO 3 ). H 3 BO 3 and Na 2 SiO 3 9H 2 O was dissolved in deionized water to form solution (a), AlCl 3 and MgCl 2 ·6H 2 O was dissolved in 1mol / L HCl solution to prepare solution (b). Prepared solutions (a) and (b) were heated and stirred on a constant temperature magnetic stirrer, and kept at a constant temperature of 60°C, then slowly added solution (a) dropwise to solution (b) under constant temperature stirring, and kept stirring at a constant temperature for 10 minutes, A homogeneous solution (c) is obtained.

[0025] (2) dropwise reaction. Use a basic burette to slowly add 3mol / L sodium hydroxide solution dropwise to the solution (c) kept at a constant temperature, and at the same time use a PHS-3C precision pH meter to detect the pH value online, and record the change o...

Embodiment 2

[0032] (1) According to the ratio of n(Mg):n(Al):n(Si):n(B)=1:2:2:1, weigh MgCl respectively 2 ·6H 2 O, AlCl 3 、Na 2 SiO 3 9H 2 O and H 3 BO 3 (unit: gram); then the H 3 BO 3 and Na 2 SiO 3 9H 2 O was dissolved in 250ml deionized water to form solution a, and the weighed AlCl 3 and MgCl 2 ·6H 2 O was dissolved in 1mol / L 250ml HCl solution to make solution b; under the condition of 60±1℃, heat and stir solution a and solution b separately, then add solution a dropwise into solution b, and Stir at constant temperature for 10-15 minutes to obtain a homogeneous solution c, in which the amount of magnesium ions is 0.01-0.04 g / ml;

[0033](2) Use a basic burette to drop a sodium hydroxide solution with a concentration of 5mol / L and a temperature of 60±1°C into the phase solution c, and check the pH value at the same time until the pH value is 9.5, and the solution produces white color. Stop the dropwise addition of flocculent precipitate and continue to stir for 1h; ...

Embodiment 3

[0038] (1) According to the ratio of n(Mg):n(Al):n(Si):n(B)=1:2:2:1, weigh MgCl respectively 2 ·6H 2 O, AlCl 3 、Na 2 SiO 3 9H 2 O and H 3 BO 3 ; Then the weighed H 3 BO 3 and Na 2 SiO 3 9H 2 O was dissolved in deionized water to form solution a, and the weighed AlCl 3 and MgCl 2 ·6H 2 O was dissolved in 1mol / L HCl solution to form solution b; solution a and solution b were heated and stirred at a constant temperature at 65°C, and then solution a was added dropwise to solution b, and stirred at a constant temperature of 60°C for 15 minutes. Obtain homogeneous solution c, wherein the amount of magnesium ions is 0.01-0.04g / ml;

[0039] (2) Use a basic burette to drop a sodium hydroxide solution with a concentration of 1mol / L and a temperature of 65°C into the phase solution c, and check the pH value at the same time until the pH value is 9, and white flocculents are produced in the solution Stop dropping the precipitate and continue to stir for 2h;

[0040] (3) Le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com