L-proline trifluoromethanesulfonic acid ammonium salt and application thereof

A technology of proline trifluoromethanesulfonate ammonium salt and trifluoromethanesulfonic acid, which is applied in the direction of sulfonate preparation, carboxylic acid amide preparation, organic compound/hydride/coordination complex catalyst, etc., and can solve the problem of catalyst Difficult to recycle, long reaction time, and limited substrate applicability, etc., to achieve the effect of recyclable price, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

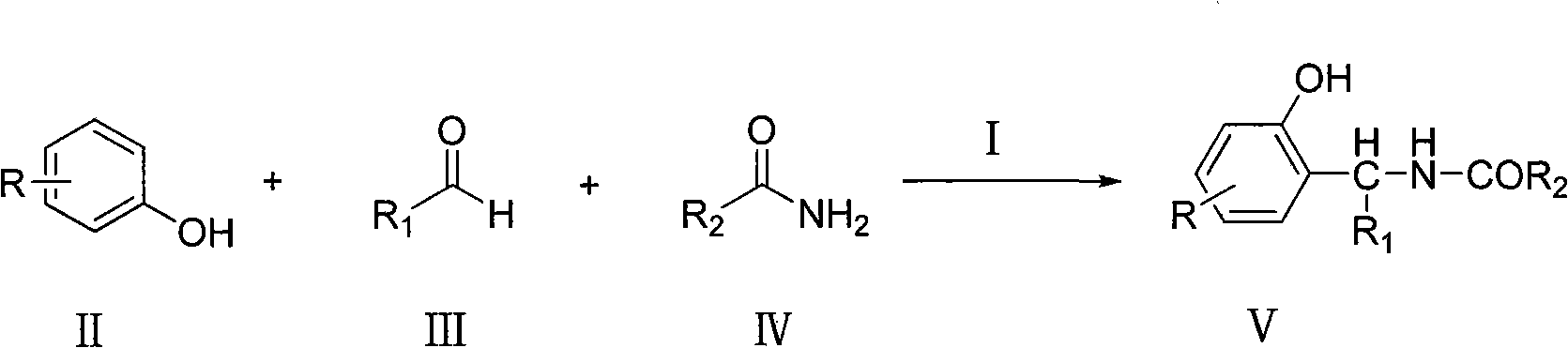

Method used

Image

Examples

Embodiment 1

[0035] Under ice-bath conditions, trifluoromethanesulfonic acid (0.750g, 5.0mmol) was slowly added dropwise to an aqueous solution (10mL) of L-proline (0.580g, 5.0mmol), and the reaction temperature was controlled at -5°C to React at 5°C for 30 minutes, wash with petroleum ether and concentrate to obtain 1.23 g of L-proline trifluoromethanesulfonate ammonium salt with a yield of 93%.

Embodiment 2

[0037] Under ice-bath conditions, trifluoromethanesulfonic acid (0.750g, 5.0mmol) was slowly added dropwise to a toluene solution (10mL) of L-proline (0.580g, 5.0mmol), and the reaction temperature was controlled at -5°C Between ~5°C, react for 30 minutes, wash with petroleum ether and concentrate to obtain 1.14 g of L-proline ammonium trifluoromethanesulfonate, with a yield of 86%.

Embodiment 3

[0039] Add 2-naphthol (0.144g, 1.0mmol), benzaldehyde (0.106g, 1.0mmol), benzamide (0.133g, 1.1mmol) and L-proline ammonium triflate in a 25mL two-necked flask Salt (0.026g, 0.1mmol) was reacted under reflux of chloroform (2mL), followed by TCL. After the reaction, extract with water and ethyl acetate, take the organic layer, concentrate, and recrystallize from ethyl acetate to obtain the corresponding condensation product with a yield of 95%.

[0040] White solid; mp 242-243°C; 1 H NMR (500MHz, DMSO-d 6 ): δ=7.20-7.32(m, 8H, Ar-H), 7.47-7.50(m, 3H, Ar-H), 7.54-7.57(m, 1H, Ar-H), 7.79-7.87(m, 4H , Ar-H), 8.08(d, J=8.5Hz, 1H, Ar-H), 9.03(d, J=8.5Hz, 1H, NH), 10.33(s, 1H, OH); 13 C NMR (100MHz, DMSO-d 6): δ=49.7, 118.8, 119.1, 123.2, 126.9, 127.0, 127.2, 127.6, 128.7, 128.8, 129.0, 129.1, 129.9, 129.1, 129.9, 131.9, 132.8, 134.8, 142.4, 153.6, 16 : 3422, 3147, 1629, 1538, 1400, 1347, 822, 751, 582cm -1 ; MS (ESI): m / z=352 [M - ].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com