Heat-sensitive recording material

一种热敏记录材料、热敏记录的技术,应用在温度记录法、复制/标记方法、印刷等方向,能够解决起雾增加、颜色灵敏度降低等问题,达到高记录密度、背景起雾的发生少、优异记录灵敏度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

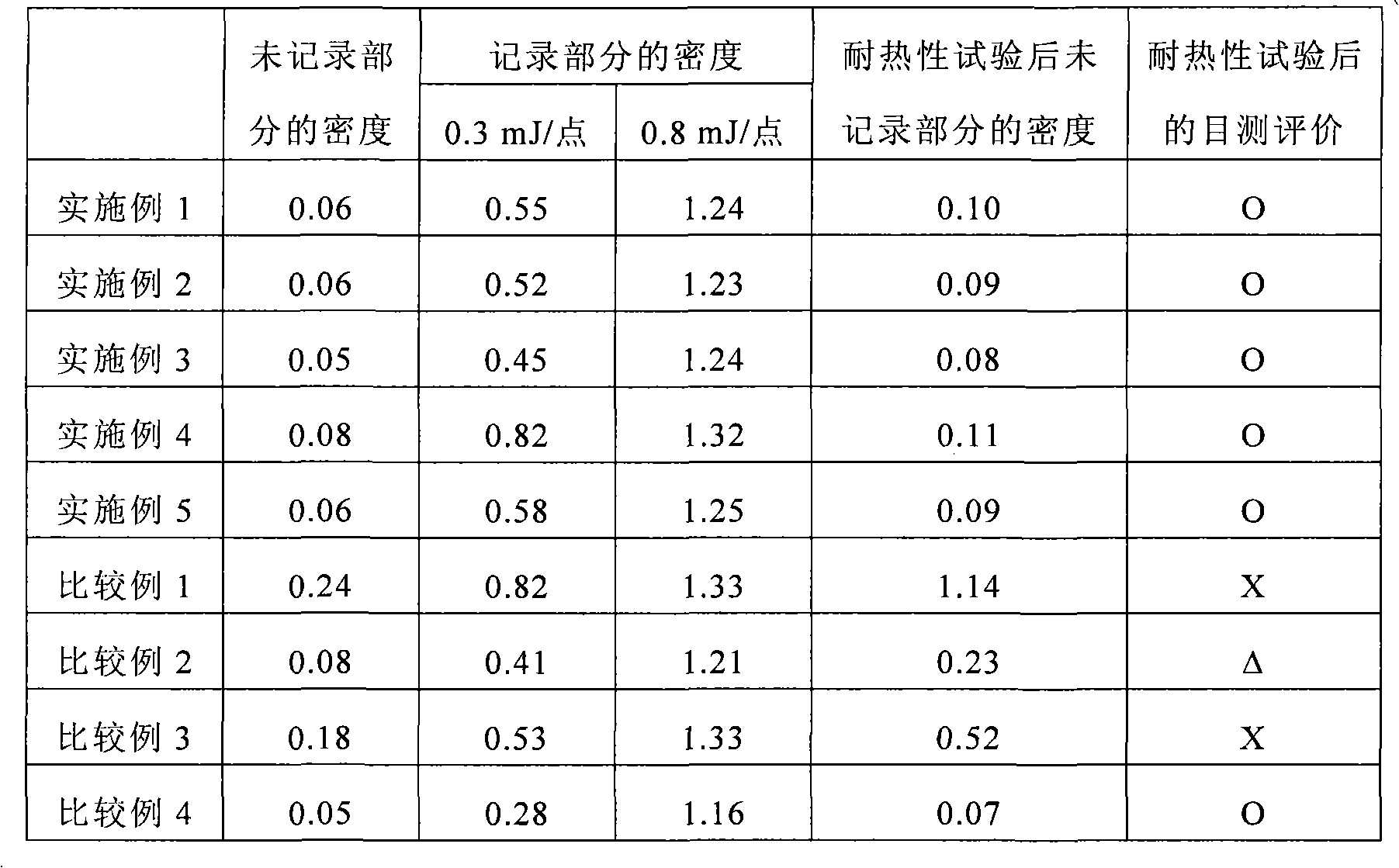

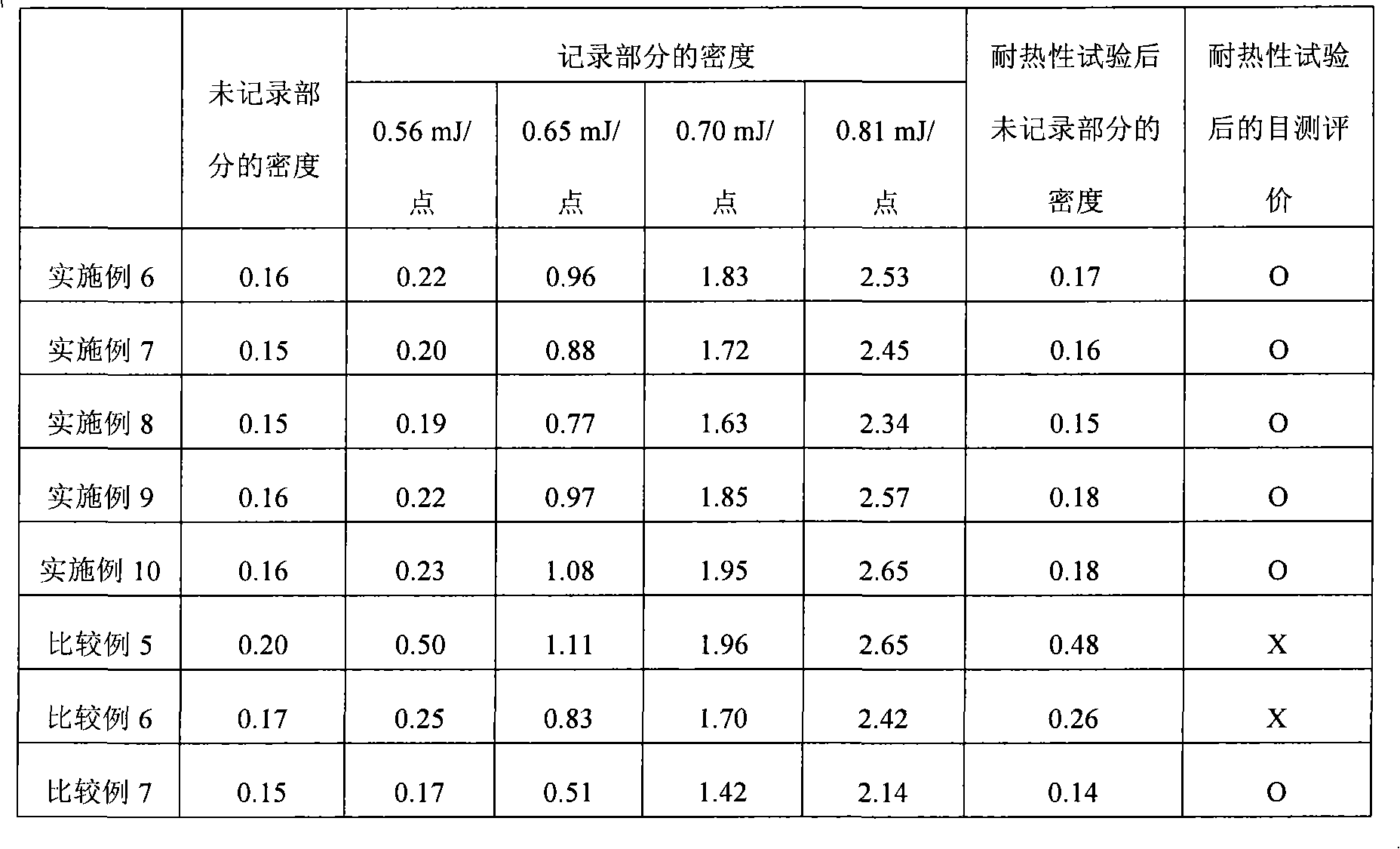

Examples

preparation example Construction

[0051] The polyvalent isocyanate compound-containing polymeric component used in the preparation of the composite particles of the present invention is a compound that forms polyurea or polyurea-polyurethane by reacting with water, and may be a single polyvalent isocyanate compound, or a polyvalent isocyanate compound A mixture with a polyol reacted with it, or an adduct of a polyol and a polyvalent isocyanate compound, or a multimer such as a biuret body or an isocyanurate body of a polyvalent isocyanate.

[0052] Examples of polyvalent isocyanate compounds used in the present invention include m-phenylene diisocyanate, p-phenylene diisocyanate, 2,6-benzylidene diisocyanate, 2,4-benzylidene diisocyanate, naphthalene -1,4-diisocyanate, diphenylmethane-4,4'-diisocyanate, dicyclohexylmethane-4,4'-diisocyanate, 5-isocyanato-1-(isocyanatomethyl) -1,3,3-trimethylcyclohexane, 3,3'-dimethyldiphenylmethane-4,4'-diisocyanate, xylylene-1,4-diisocyanate, m-tetramethyl Xylylene diisocyan...

Embodiment 1

[0125] Preparation of Composite Particle Dispersion Liquid (Liquid A) Containing Dye Precursor

[0126] As a dye precursor, 20 parts of 3-bis(n-butyl)amino-6-methyl-7-anilinofluoran was dissolved in 24 parts of dicyclohexylmethane-4,4'-bis Isocyanate (trade name: Desmodur (registered trademark) W; manufactured by Sumika Bayer Urethane Co., Ltd.). This solution was gradually added to 200 parts of an aqueous solution of 6% polyvinyl alcohol (trade name: Poval (registered trademark) PVA217EE; manufactured by Kuraray Co., Ltd.), using a homogenizer (trade name : T.K.ROBO MICS; manufactured by Tokushu Kika Kogyo Co., Ltd.) Stirring at 7,000 rpm for 2 minutes for emulsification and dispersion. Gained emulsion is heated to 90 DEG C, add 20 parts of polyethyleneimine (trade name: Epomin (registered trademark) SP-003) that has the branched structure that contains primary amine, secondary amine and tertiary amine and molecular weight is 300 as reaction accelerator ; manufactured by ...

Embodiment 2

[0134] A thermosensitive recording material was obtained in the same manner as in Example 1, except that, in the preparation of Liquid A, 20 parts of amines having a branched structure containing primary amines, secondary amines, and tertiary amines and having a molecular weight of 600 were used. A 10% aqueous solution of polyethyleneimine (trade name: Epomin (registered trademark) SP-006; manufactured by Nippon Shokubai Co., Ltd.) was used as a reaction accelerator instead of 20 parts having a branched structure containing primary, secondary, and tertiary amines. And a 10% aqueous solution of polyethyleneimine with a molecular weight of 300 (trade name: Epomin (registered trademark) SP-003; manufactured by Nippon Shokubai Co., Ltd.). At this time, the average particle diameter of the composite particles was 1.0 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com