Once-through isothermal methanol-methanation advanced purification process and device

A deep purification device and deep purification technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as low load, increased compressor power consumption, and large compressor impact, and reduce investment and energy consumption, reduced cooling water consumption, and greater operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

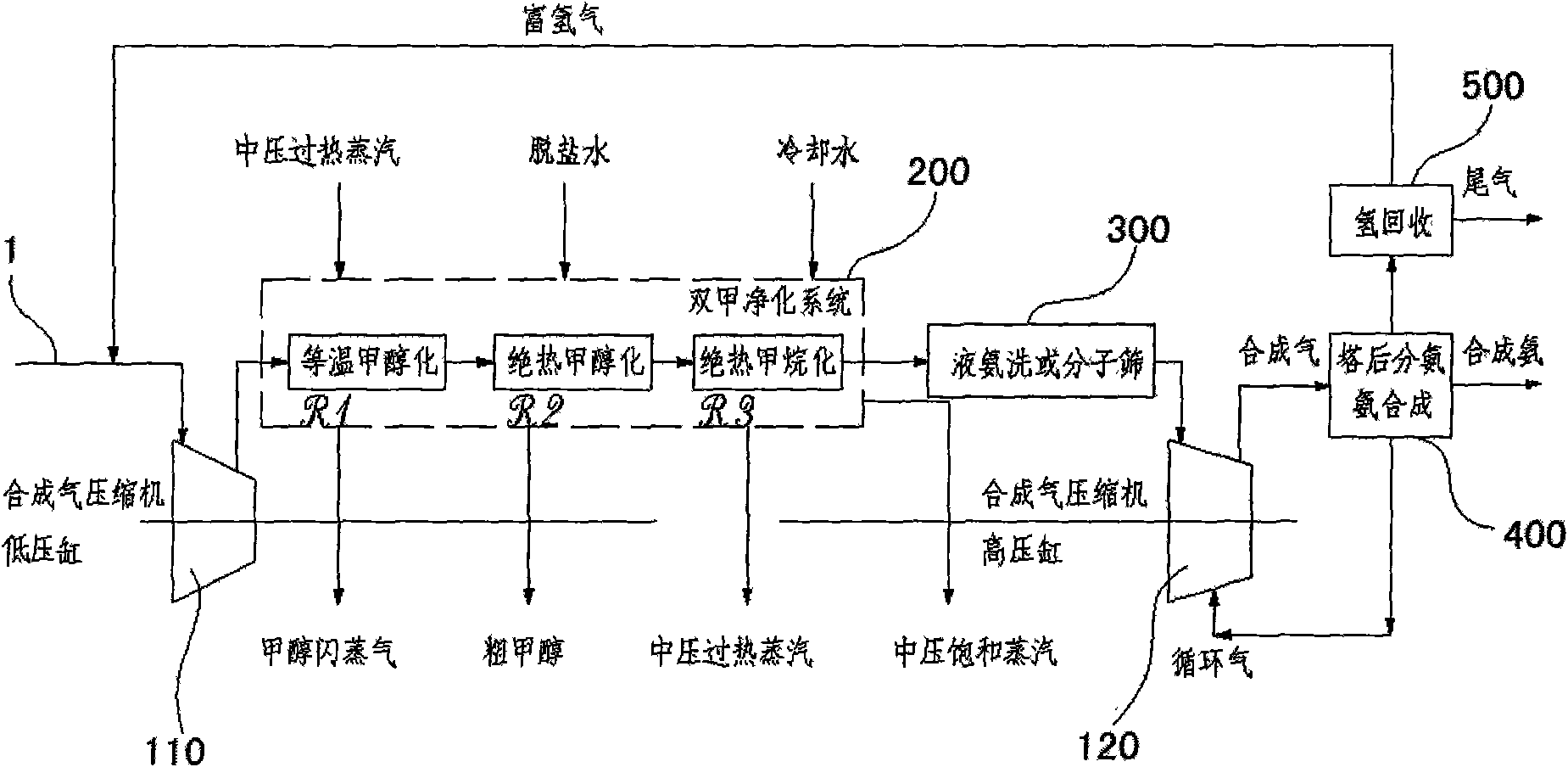

Embodiment 1

[0042] This embodiment is applied to a new device, and its energy saving effect is obvious. The one-pass isothermal double-A deep purification device of this embodiment includes a syngas compressor, which is a centrifugal compressor, and has a low-pressure cylinder 110 and a high-pressure cylinder 120, and also includes a double-A deep purification device. 300, the double A deep purification device 200 is composed of an isothermal methanolization reactor R1, an adiabatic methanolization reactor R2 and an adiabatic methanation reactor R3 in series.

[0043] The process gas 1 from the shift desulfurization and decarburization, after being compressed by the low pressure cylinder 110 of the compressor, enters the double-A deep purification device 300 under the pressure of 5.0-8.0 MPa. The process gas 1 is first preheated to a temperature of 200-250°C and then enters the isothermal methanolization reactor R1. The isothermal methanolization reactor R1 produces medium-pressure satura...

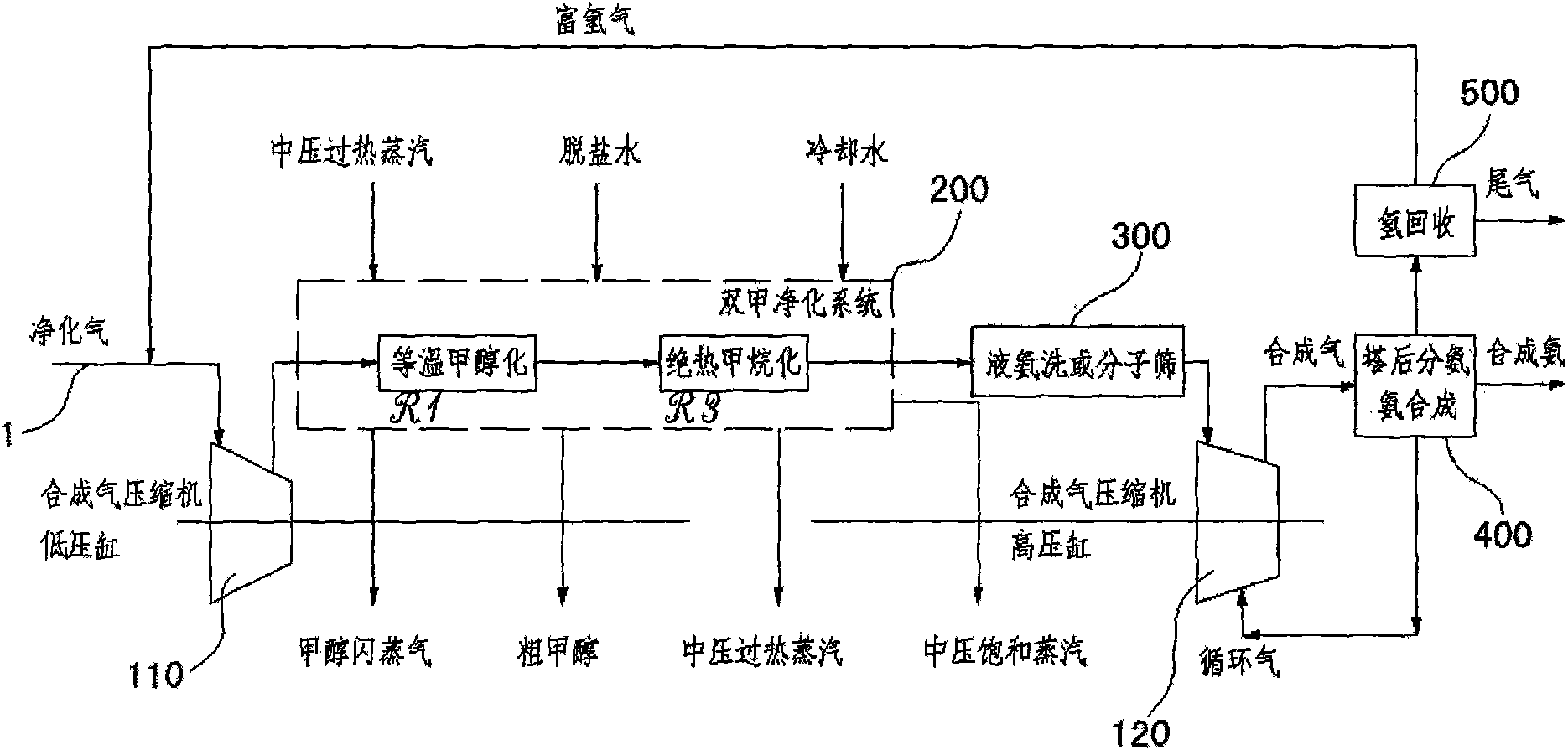

Embodiment 2

[0047] If the total carbon content in the desulfurized and decarbonized feed gas decreases, the following Example 2 can be used to reduce investment. The only difference in this embodiment is that the double-methyl deep purification device 200 is different from the embodiment 1, and is composed of an isothermal methanolization reactor R1 and an adiabatic methanation reactor R3 connected in series. The rest is the same as in Example 1.

[0048] The process gas 1 from the shift desulfurization and decarburization, after being compressed by the low pressure cylinder 110 of the compressor, enters the double-A deep purification device 300 under the pressure of 5.0-8.0 MPa. The process gas 1 is first preheated to a temperature of 200-250°C and then enters the isothermal methanolization reactor R1. The isothermal methanolization reactor R1 produces medium-pressure saturated steam by-product, and the reaction temperature is controlled by the pressure of the by-produced saturated steam...

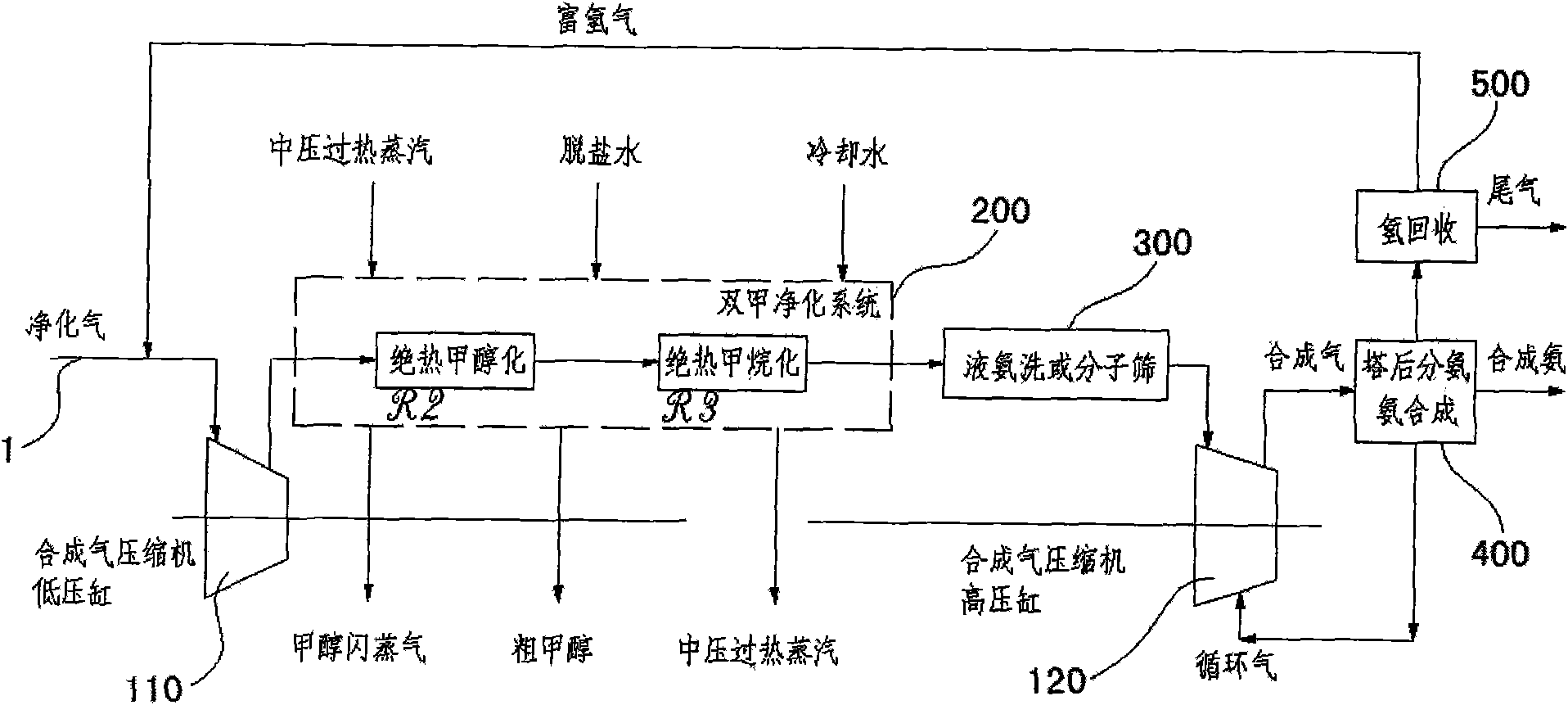

Embodiment 3

[0052] If the total carbon content in the desulfurization and decarbonization feed gas is further reduced, the following Example 3 can be used to further reduce the investment; the application in the retrofit device has obvious effect of energy saving and production increase. The only difference in this embodiment is that the double-methyl deep purification device 200 is different from the embodiment 1, and is formed by connecting an adiabatic methanolization reactor R2 and an adiabatic methanation reactor R3 in series. The rest is the same as in Example 1.

[0053] The process gas 1 from the shift desulfurization and decarburization, after being compressed by the low pressure cylinder 110 of the compressor, enters the double-A deep purification device 300 under the pressure of 5.0-8.0 MPa. The process gas 1 is first preheated to a temperature of 200-230 °C and then enters the adiabatic methanolization reactor R2, and the remaining CO+CO 2 further converted to methanol. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com