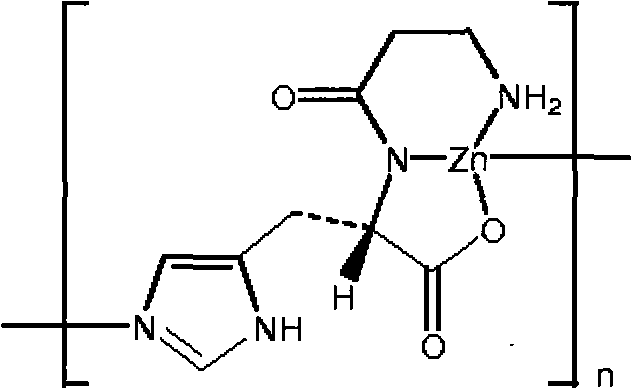

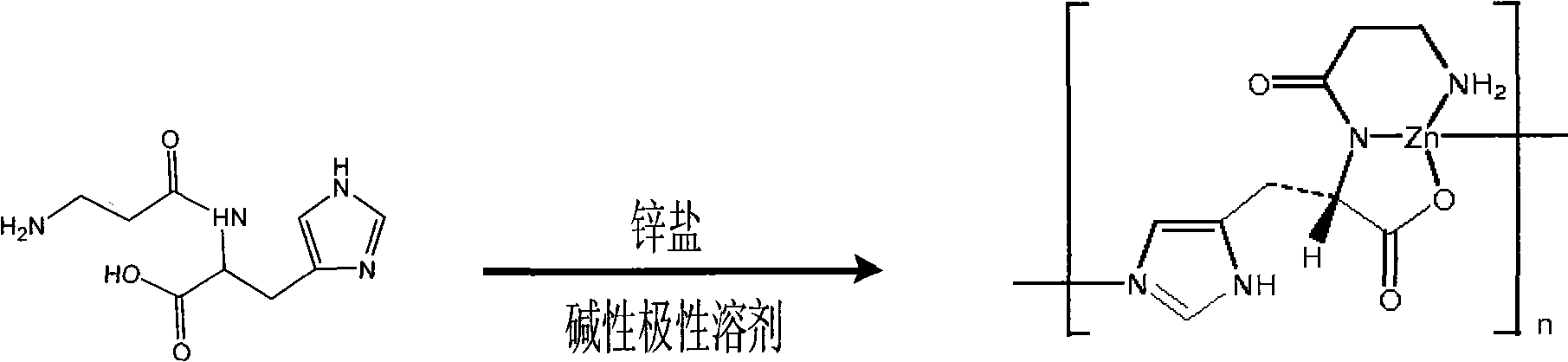

Preparation method of L-carnosine zinc

A technology of carnosine zinc and carnosine, which is applied in the field of preparation of pharmaceutical intermediates, can solve the problems of low utilization rate of raw materials, high residual salt content, large solvent consumption, etc., and achieves the effects of reducing preparation cost, good yield and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Get 2.5g of L-carnosine with an optical purity of more than 99.5%, dissolve it with 500g of pure water, and get the commodity model D201 macroporous anion-exchange resin prepared in advance, preferably but not limited to, produced by Langfang New Times Chemical Co., Ltd., Hebei Province, China That is, 100 g of macroporous basic anion exchange resin is dropped into the above-mentioned L-carnosine aqueous solution, stirred for 2.0 h (static adsorption), the temperature is controlled at 5-10 ° C, the adsorbed resin is packed into a column, and the mass percentage concentration is 2% ZnCl 2 Reverse elution with aqueous solution, the temperature during elution is controlled at 15-20°C, and the elution rate is controlled at 5.0-6.0vvh -1 . As the elution proceeds, the generated L-carnosine zinc is precipitated from the aqueous solution. When no solid is washed out in the eluent, the eluent containing L-carnosine zinc is combined, and dried at 80°C after solid-liquid separati...

Embodiment 2

[0028] Get the L-carnosine 5.0g more than 99.5% of optical purity, dissolve with 500g pure water, get the ion-exchange resin 100g described in embodiment 1 of pretreatment and drop into above-mentioned L-carnosine aqueous solution, stir 2.0h (static adsorption: Static adsorption The specified amount of adsorbent and quantitative solution reach equilibrium after a long time of full contact.), the temperature is controlled at 5-10 ° C, the adsorbed resin is packed into a column, and ZnCl with a zinc ion mass concentration of 2% 2 Reverse elution with aqueous solution, the temperature during elution is controlled at 20-30°C, and the elution rate is controlled at 5.0-6.0vvh -1 . As the elution proceeds, the generated L-carnosine zinc is precipitated from the aqueous solution. When no solid is washed out in the eluent, the eluent containing L-carnosine zinc is combined, and after solid-liquid separation, it is dried at 80°C to obtain L- Carnosine zinc product 6.2g. Mass yield: 12...

Embodiment 3

[0030] Get L-carnosine 20g more than 99.5% of optical purity, dissolve with 1000g pure water, get pretreated D201 (commercial model, macroporous anion exchange resin is macroporous basic anion exchange resin) ion exchange resin 200g packing column, will The above-mentioned carnosine solution passes through the installed ion-exchange column for adsorption and activation (dynamic adsorption), the temperature is controlled at 0-5°C, and the flow rate is controlled at 1.0vvh -1 , after the activation of the carnosine solution on the column, use ZnCl with a zinc ion mass concentration of 2% 2 Reverse elution with aqueous solution, the temperature during elution is controlled at 20-30°C, and the elution rate is controlled at 5.0-6.0vvh -1 . As the elution proceeds, the generated L-carnosine zinc is precipitated from the aqueous solution. When no solid is washed out in the eluent, the eluent containing L-carnosine zinc is combined, and after solid-liquid separation, it is dried at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical rotation | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com