O-type aftosa synthetic peptide vaccine

A technology for synthesizing peptide vaccines and foot-and-mouth disease, which is applied in the field of polypeptides or their polypeptide polymers, can solve problems affecting the use of new vaccines, achieve good application prospects, high immune response levels, and enhance immune effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The solid-phase synthesis of embodiment 1 foot-and-mouth disease synthetic peptide antigen

[0034] The polypeptide antigen of the present invention can be prepared by using ABI 433A automatic polypeptide synthesizer and Merrifield solid-phase synthesis method, wherein 9-fluorenylmethoxycarbonyl (Fmoc) modified amino acid is used, and the solid phase carrier is Rink Amide MBHA resin. The production process usually includes solid-phase synthesis of polypeptide antigens, cleavage of polypeptides, purification of antigens and sterilized storage.

[0035] 1.1 Solid phase synthesis of polypeptide antigen

[0036] 1.1.1 Preparation of synthetic raw materials

[0037] The sequences of the synthetic polypeptide antigens are respectively shown in SEQ ID NO: 1, SEQ ID NO: 2, and SEQ ID NO: 3.

[0038] According to the sequence of the antigen and the synthesis scale, 1 mmol of the appropriate Fmoc-modified amino acid was prepared and added to the corresponding amino acid vial. ...

Embodiment 2

[0063] Example 2. Preparation of synthetic peptide vaccines

[0064] 2.1 Preparation of antigen aqueous phase

[0065] First, weigh the three peptide antigens synthesized according to the above-mentioned Example 1; then, dilute the concentration of the synthesized peptide antigen to 50 μg / ml with sterile water for injection; filter the antigen solution through a filter with a pore size of 0.2 μm, and sterilize .

[0066] 2.2 Preparation of oil phase adjuvant

[0067] Sterilize the oil-phase adjuvant at 121°C for 30 minutes, and set aside.

[0068] 2.3 Emulsion of synthetic peptide vaccine

[0069] Clean the IKA emulsification equipment with 2000ml of sterilized distilled water for 3 times, then put the oil phase into the emulsification tank at 20-28°C according to the volume ratio of oil phase adjuvant and antigen water phase of 1:1, and start the motor to After stirring at a slow speed of 90-150r / m for 2 minutes, slowly add the water-phase antigen at the same time, stir f...

Embodiment 3

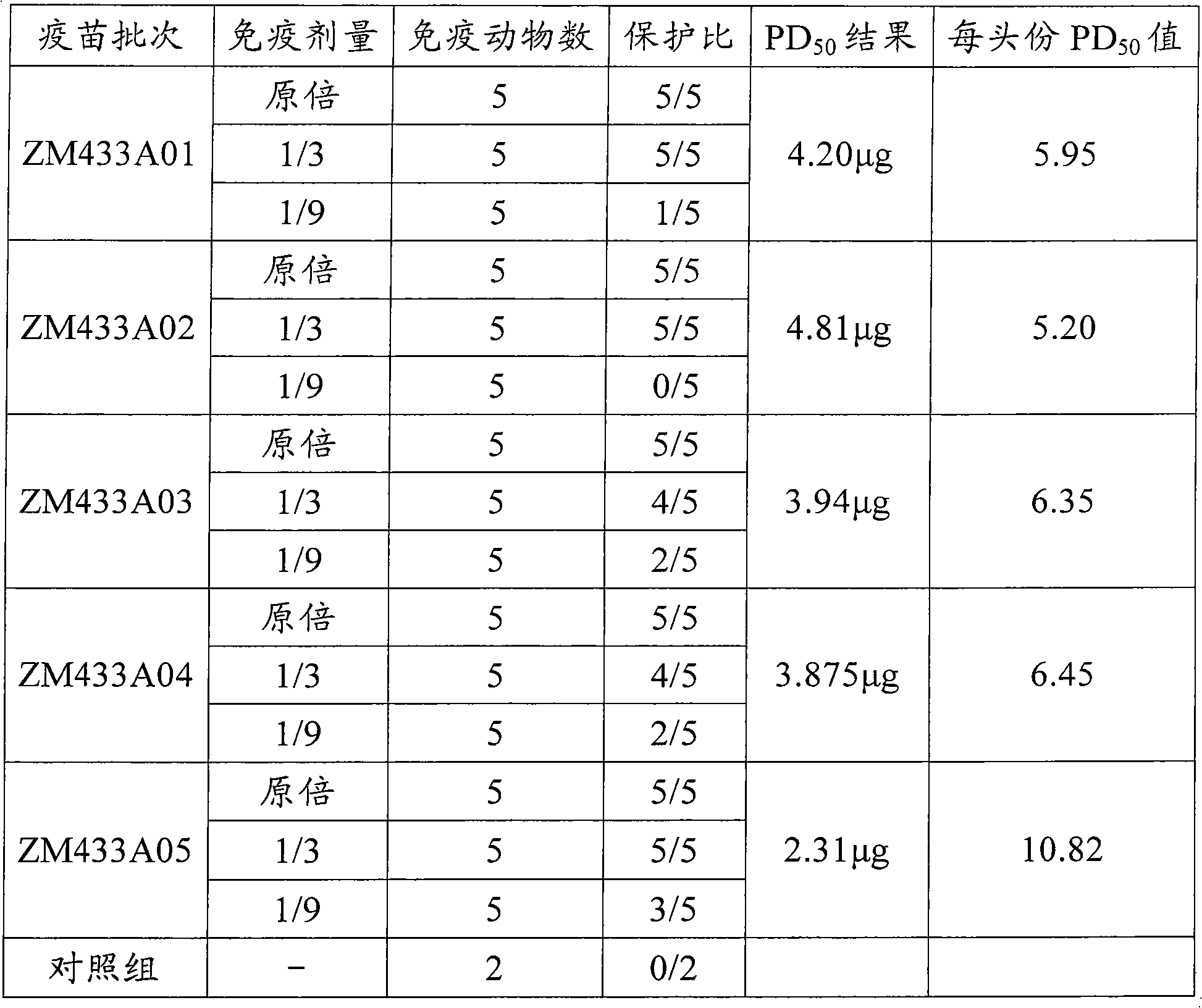

[0070] Efficacy test of embodiment 3 swine foot-and-mouth disease O type synthetic peptide vaccine

[0071] 1. Materials and methods

[0072] 1.1 Synthetic peptide vaccine

[0073] Synthesize polypeptide antigens with SEQ ID NO: 1, SEQ ID NO: 2, and SEQ ID NO: 3 sequences according to the above-mentioned examples, and then prepare the corresponding batch numbers: ZM433A01, ZM433A02, and ZM433A03 swine foot-and-mouth disease O-type synthetic peptides vaccine.

[0074] In addition, all valines in the amino acid sequence in SEQ ID NO: 1 were replaced with norvaline; all leucines were replaced with norleucine, and the antigen was synthesized according to the method provided in the above examples. The batch number of the prepared vaccine was: ZM433A04.

[0075] According to the sequence of SEQ ID NO: 1, the dimer antigen of this sequence was synthesized by conventional synthetic peptide technology, and the vaccine was prepared to obtain the synthetic peptide vaccine with batch n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com